Troubleshooting Common Wear Issues in HPGR Tungsten Carbide Flanges

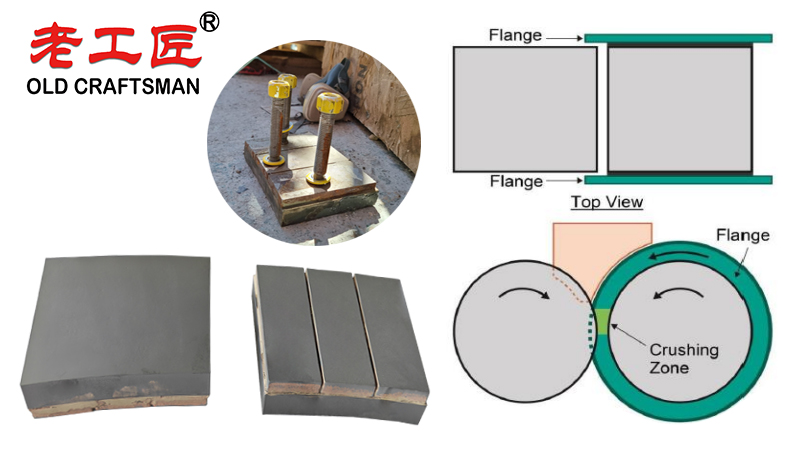

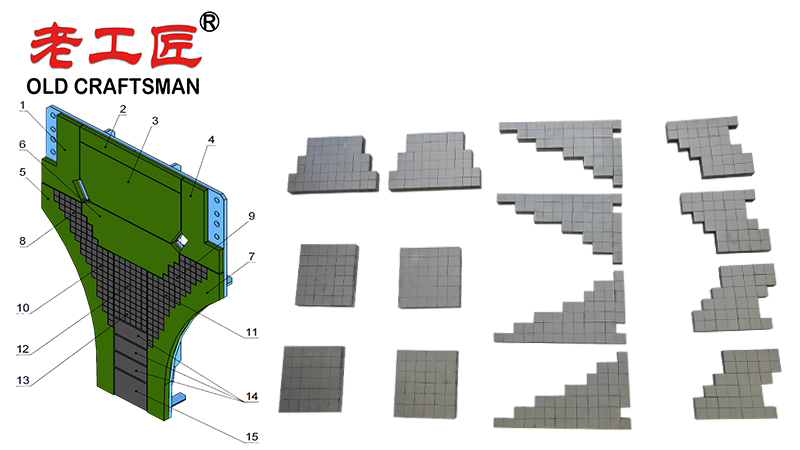

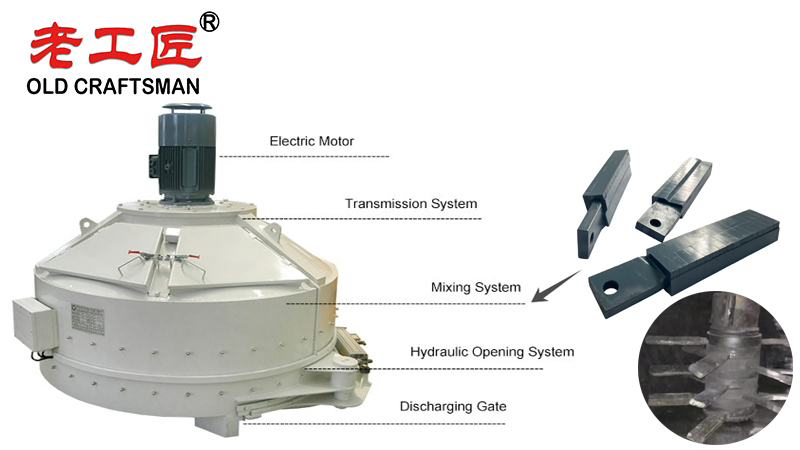

ZZ OLD CRAFTSMAN makes tungsten carbide wear plates are mainly used as transfter chute, HPGR cheek plate, HPGR flange, HPGR corner block etc.

Troubleshooting Common Wear Issues in HPGR Tungsten Carbide Flanges Read More »