A Step-by-Step Guide of Manufacturing New Refractory Molds

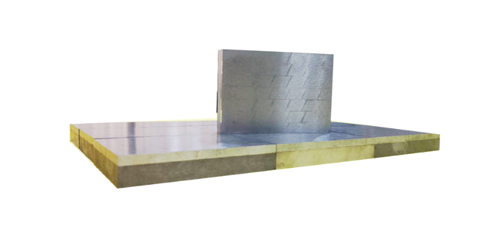

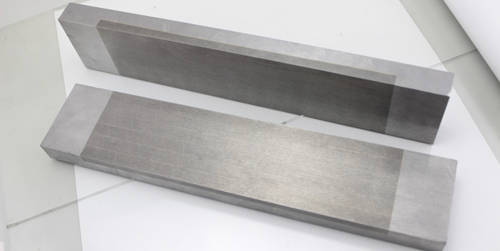

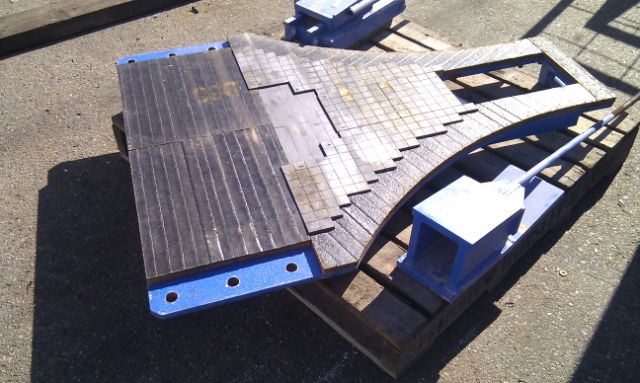

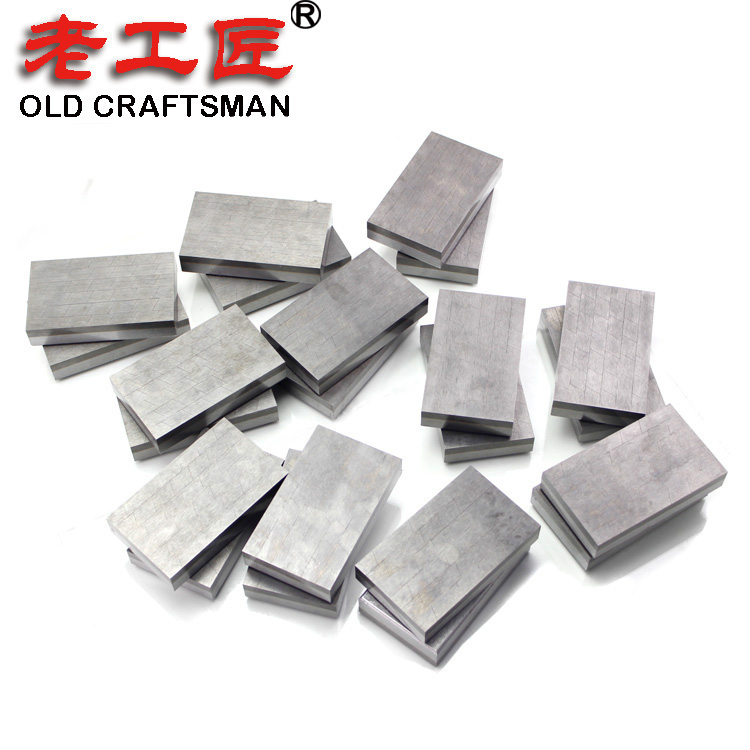

A Step-by-Step Guide of Manufacturing New Refractory Molds Content: Introduction to a new Mold Design Mold is an important tool necessary for manufacturing industrial products, and the material used to create itself is one of the key factors affecting the performance of the mold. Traditional mold materials are mainly metal and ceramic, but these materials […]

A Step-by-Step Guide of Manufacturing New Refractory Molds Read More »