How Tungsten Carbide Chute Liners Resist Wear and Tear in Mining

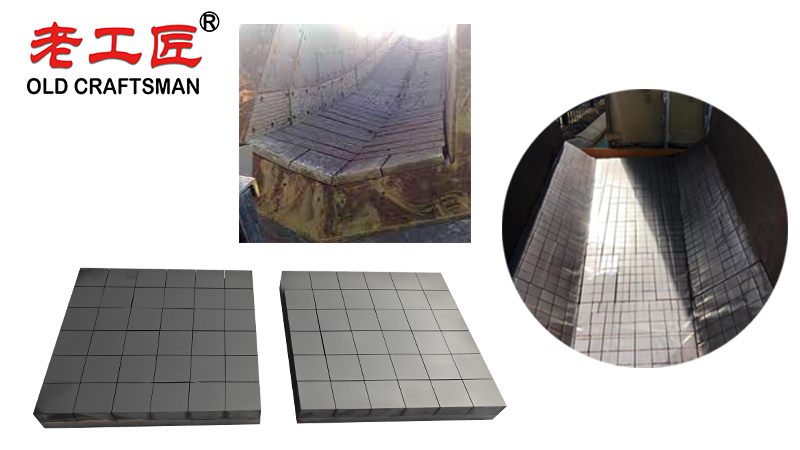

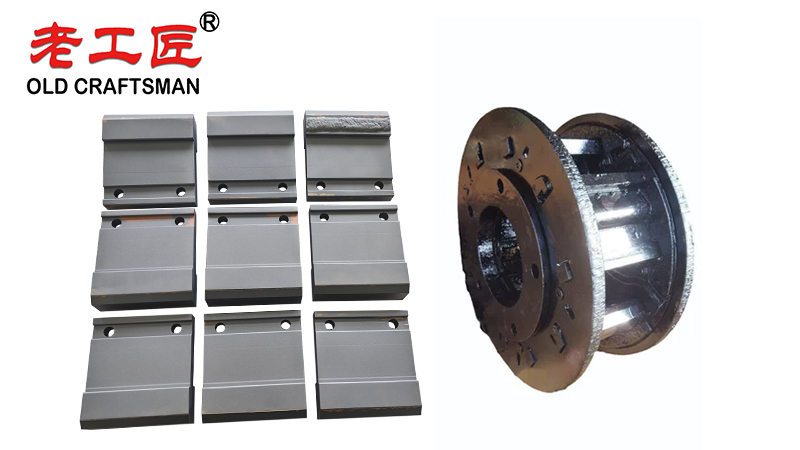

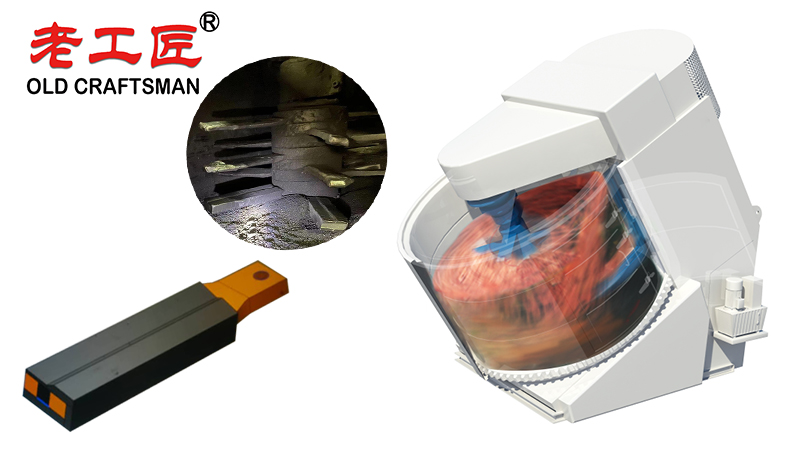

“ZZ OLD CRAFTSMAN makes tungsten carbide wear plates are mainly used as transfter chute, carbide cheek plate, flange, corner block etc.”

How Tungsten Carbide Chute Liners Resist Wear and Tear in Mining Read More »