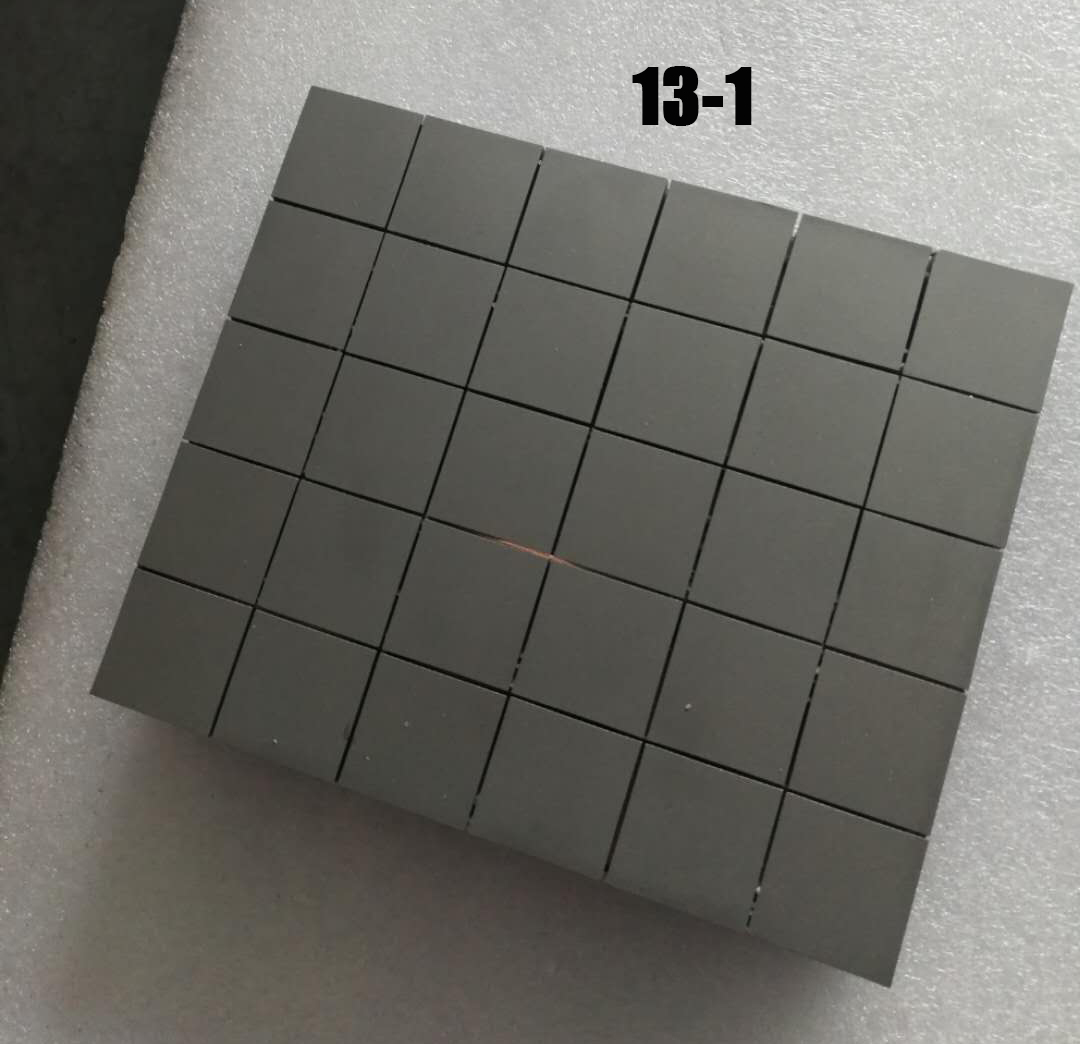

Tungsten Carbide Crusher Hammer Use Life is Tens of Times Longer Than The High Chrome Crusher Hammers

Tungsten carbide crusher hammers also with other expresses, like hard alloy crusher hammers, hard alloy crusher hammers, cemented carbide crusher hammer, carbide alloy crusher hammer, hard metal crusher hammer.