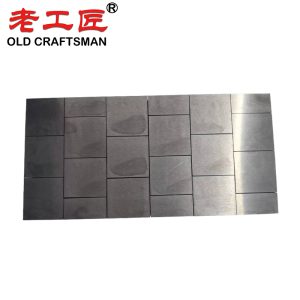

I. ZZ craftsman researched and developed the carbide vacuum brazed wear liners for 10 years

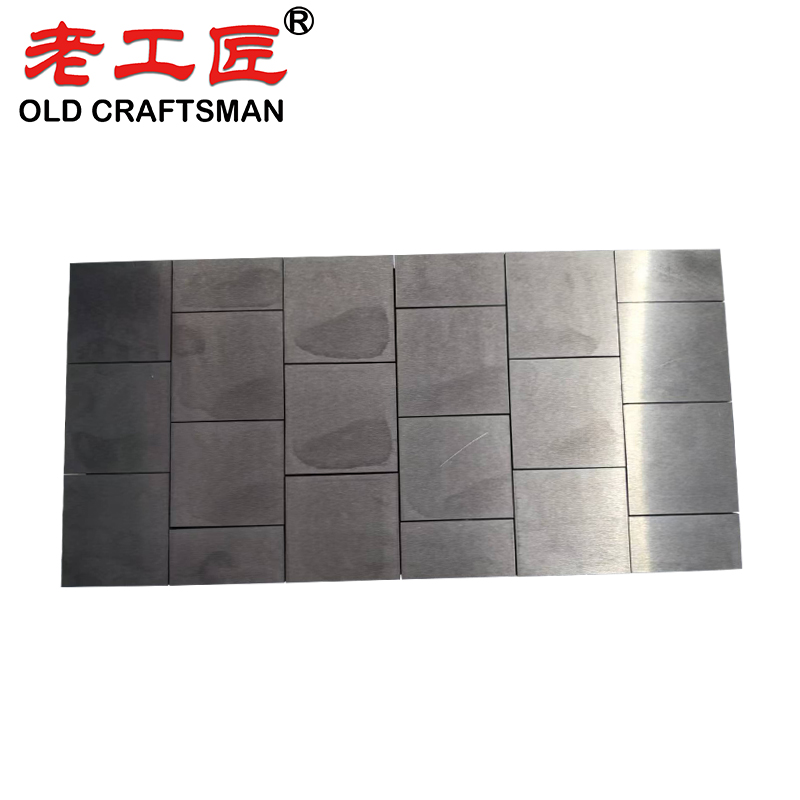

Artwork Advantages:

- “Hardness: HRA 89-91”

- “Customizable Thickness for Your Needs”

- “Proven in Iron Ore and Copper Mining”

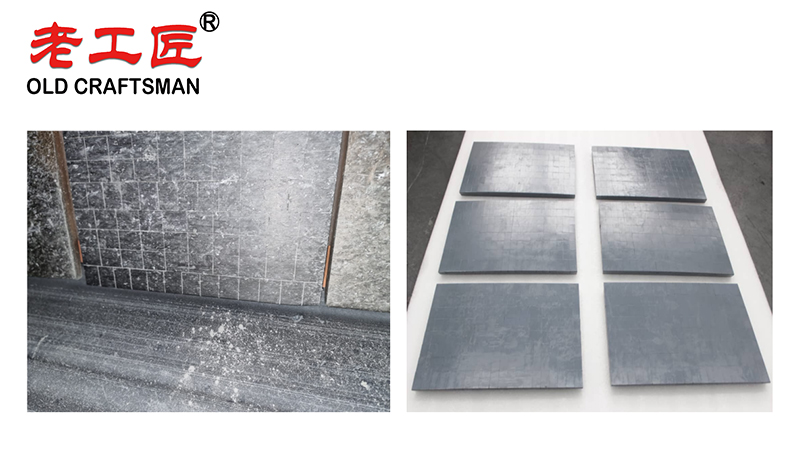

ZZ Craftsman’s carbide vacuum-brazed wear liners are a breakthrough innovation after 10 years of R&D. Traditional mining liners—steel, ceramic, urethane, plastic, Nitronic SX, chromium carbide, rubber—are cost-effective but fall short as labor costs rise, competition intensifies, and efficiency demands grow.

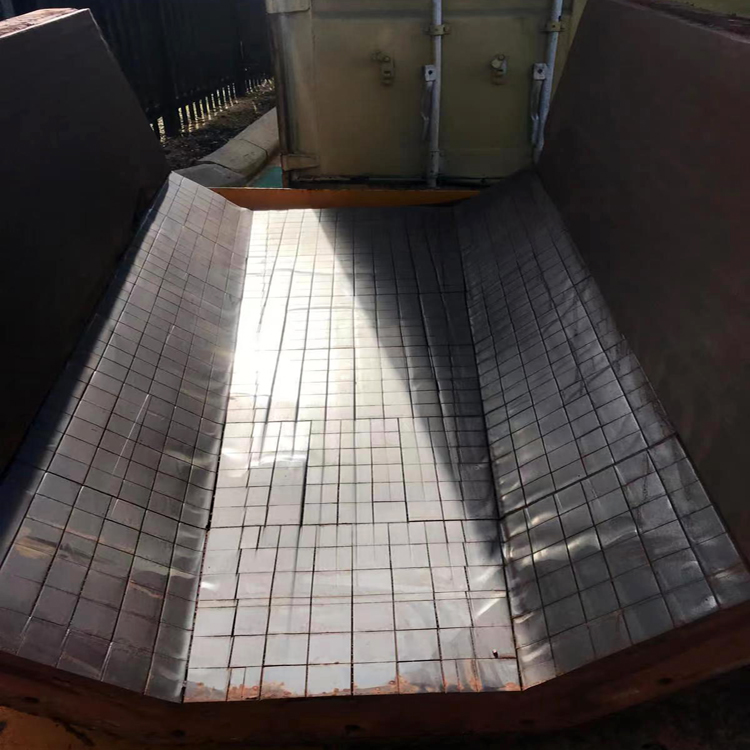

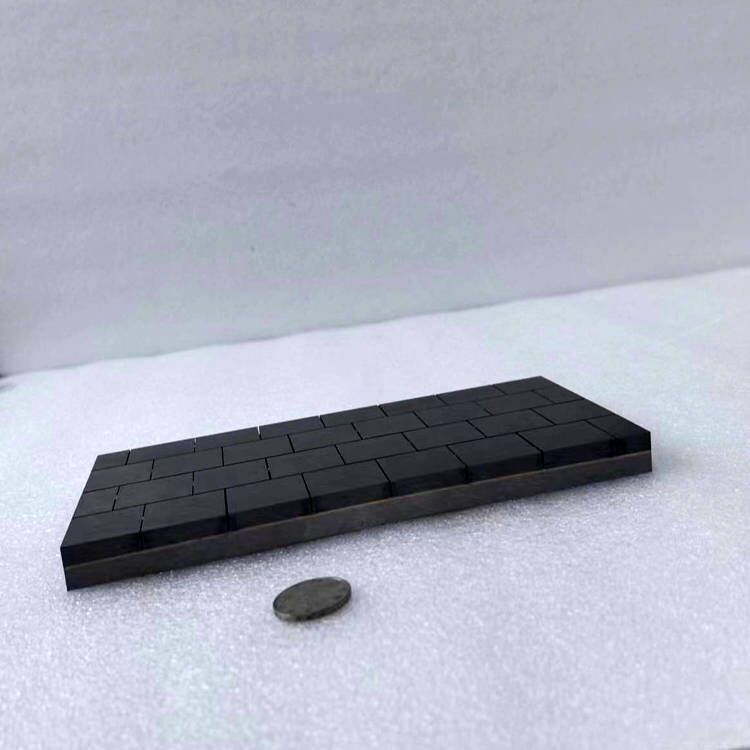

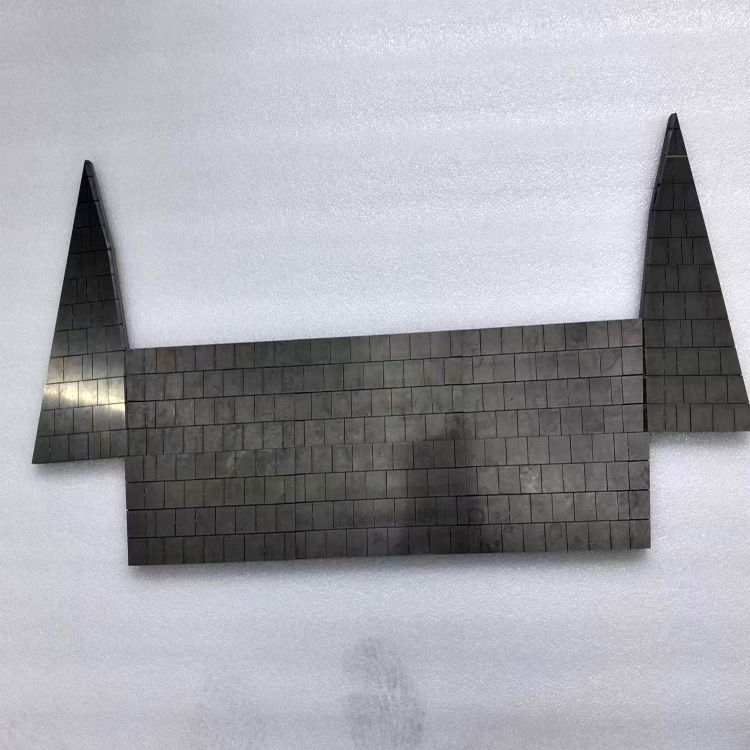

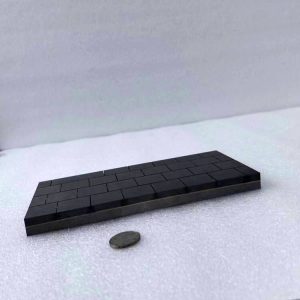

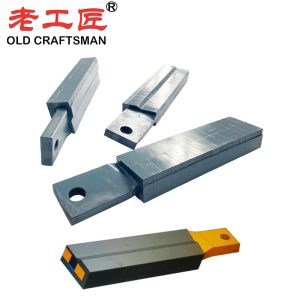

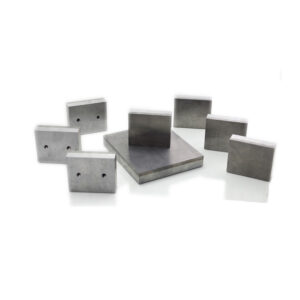

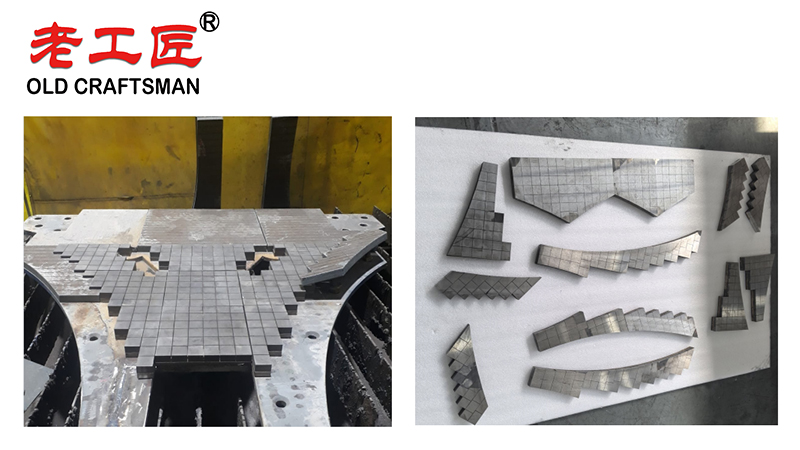

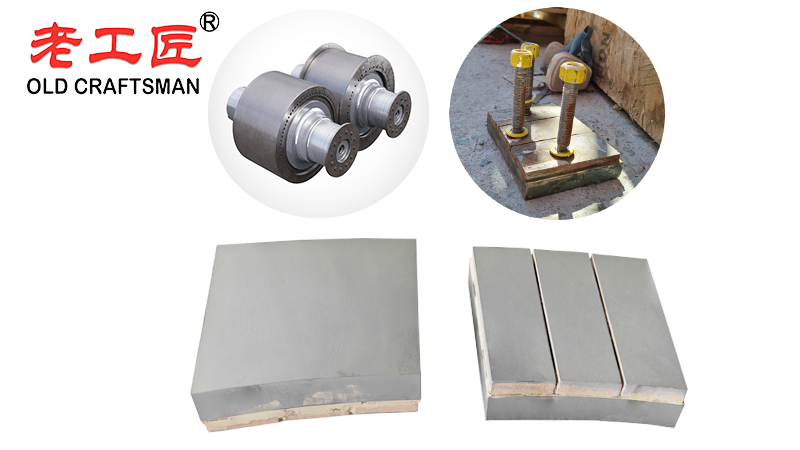

Our vacuum brazing perfectly bonds tungsten carbide to steel, enabling any shape, including curves, and thriving in extreme heat, cold, or impact. Ideal for chutes, crushers, feeders, conveyors, and mills, they streamline material flow.

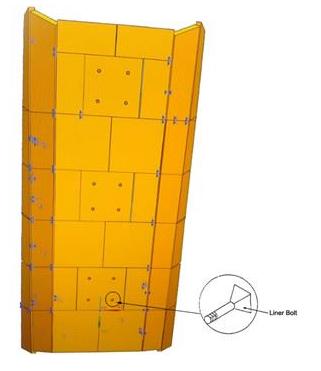

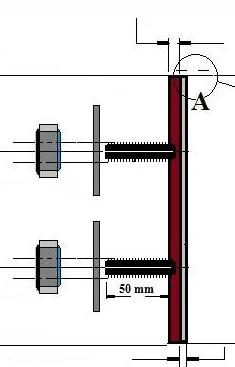

Installation is simple: studs pre-brazed on backing plates allow direct bolting to chutes.

For more detailed introduction, welcome to check on Chute Liner – ZZ Old Craftsman (zzcraftsman.com)

II. ZZ craftsman design, assist sample testing, assist in adjusting the carbide grade and brazing technique according to the test result, small sample testing to middle sample testing to buck production.

- Provide CAD drawings for confirmation according to customer requirements before arranging production.

- Make samples for comparing the service life with traditional wear liners.

- If there is a problem during sample testing, we will carefully analyze the rejected products to find out the problem, then adjust the sample production process and provide new samples for testing.

- After small batch sample testing, we usually recommend customers conduct medium batch sample testing and then proceed to mass production.

Through these steps, testing costs can be reduced and customers can have more confidence in our company’s products.

III.Why zz craftsman insists on the vacuum brazing for the wear liners?

Brazing has long struggled with carbide oxidation and degradation. Steel’s thermal expansion is 4× that of carbide, creating massive internal stress in large-area brazing, leading to cracks, brittleness, tile detachment, and short lifespan. ZZ Craftsman’s vacuum brazing eliminates oxidation in a vacuum environment and pairs with proprietary heat treatment to fully relieve stress, preventing cracking and fallout for superior durability.

IV.WHAT ZZ CRAFTSMAN CAN PROVIDE FOR YOU?

- We can help you to make new designs to improve the current products’ working efficiency;

- We can help you to solve the wear problem that is occurring from the current material;

- We can help you adjust the production technique if any problem occur during the testing

- We can provide suggestions if customers do not have good ideas on the improvement.

V. Application of wear liner:

Ideal for iron ore transfer chutes in Australia” or “Perfect for copper ore processing in Peru”.

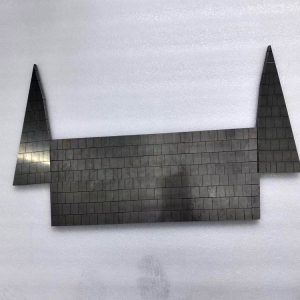

Applications involving severe sliding abrasion and medium impact, such as

- Chutes

- Deflector chutes

- Ore Handling Systems

- Liner Plates

- Hoppers

- Conveyor skirts

- Conveyor dragplates

- HPGRfeed cheek plates

- HPGR flange

Wear Liners Mining

Chute Lining

Chute Wear Liners

Chute Liner Material

Chute Liners Mining

Conveyor Chute Liners

Mining Hopper

Hopper Plate

Hopper Material Handling

Hopper Feeder Mining

High Pressure Grinding Rolls

High Pressure Grinding Rollers

High Pressure Grinding Roll

HPGR

HPGR Weir

HPGR Mining

Carbide Wear Plate

Mining Wear Plate

HPGR Wear Plate

Mining Wear Plates

Wear Plate For Mining

HPGR Edge Block

Edge Block HPGR

HPGR Flange

HPGR Cheek Plate

Carbide Wear Liner

Vacuum Brazed Wear Liner

Lining Plate

Mining And Quarrying Wear Liner

HPGR Liners

Welcome to contact us for the customized design!

Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.

VI. FAQ of the wear liner

Q: What are your main products for tungsten carbide brazing?

A: Our advantage products are brazed carbide wear plates, brazed carbide crushing hammerheads, brazed carbide nozzles, brazed carbide scrape blades, brazed liners for refractory brick mold, and any of customized brazed items.

Q: Do you have an OEM&ODM option?

A: Yes, we have. Customized product is our advantage.

Q: What is your MOQ?

A: It depends on the exact product; there usually is no MOQ limitation for standard products.

Q: How long have you been producing this product?

A: We have been doing research and development, and producing carbide brazing products for over 8 years, gaining much successful experience in it.