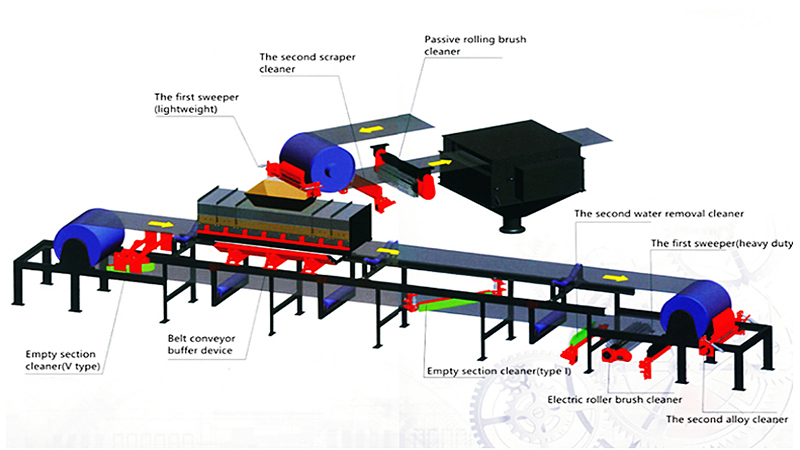

The installation location of a mining conveyor belt cleaner depends on its type and purpose, but it is typically placed at key points in the conveyor system to effectively remove residual material from the belt surface, preventing buildup and equipment damage. Here are the common installation locations:

1.Primary Cleaner

- Installation Location: Usually installed near the head pulley, right after the material is discharged.

- Purpose: Removes the majority of coarse material stuck to the belt.

2.Secondary Cleaner

- Installation Location: Positioned below the head pulley or at the start of the return side, following the primary cleaner.

- Purpose: Further removes fine particles or wet, sticky material for enhanced cleaning.

3.Return Side Cleaner

- Installation Location: Mounted on the return side of the conveyor belt, typically near the tail pulley or tensioning device.

- Purpose: Cleans the underside of the return belt to prevent material buildup on rollers or support structures.

Installation Considerations:

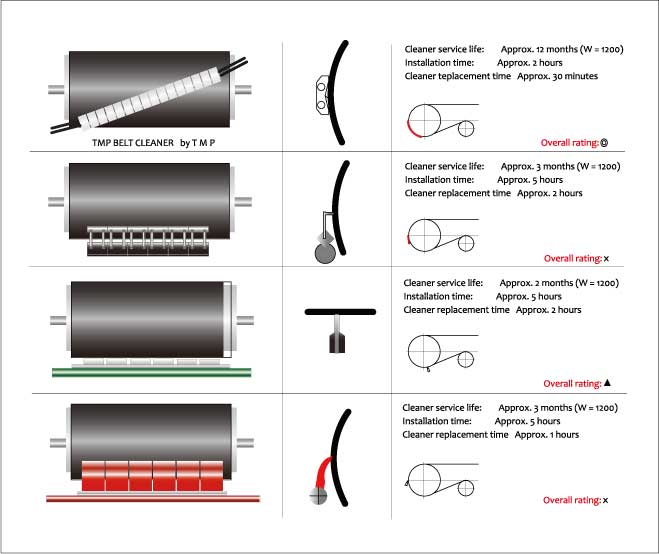

- Angle and Pressure: The cleaner’s blade or brush should maintain an appropriate angle and pressure against the belt surface effective for cleaning without causing excessive wear.

- Equipment Type: Select a cleaner (e.g., scraper, brush, or water spray) based on the mining environment, such as humidity or material stickiness.

- Maintenance Access: The installation spot should allow easy inspection and replacement of cleaning components.

A mining conveyor belt cleaner is a critical device designed to maintain the efficiency and longevity of conveyor systems in mining operations. Its primary function is to remove residual materials such as ore, dust, or sticky substances from the conveyor belt surface after unloading. By preventing material buildup, it reduces the risk of belt slippage, misalignment, or damage to rollers and pulleys, which can lead to costly downtime. Cleaners also enhance safety by minimizing spillage that could create hazards in the work environment. Available in types like primary, secondary, and return side cleaners, they target different sections of the belt, ensuring thorough cleaning. Conveyor belt cleaners help improve efficiency, lower maintenance costs, and extend equipment life. They are essential for safe and productive mining.

A high performance conveyor belt system is the backbone of efficient bulk material handling in demanding industries. These systems are made for heavy duty jobs and can handle thousands of tons each hour. They use different types of belts, such as modular belts, PVC, rubber, and belts with an anti-slip surface. These belts help move items smoothly along assembly lines and in processing plants. At critical transfer points, proper conveyor equipment such as primary and secondary belt scrapers minimizes carryback, reduces premature wear and tear on belt surfaces, and protects the drive pulley. Whether using trough, flat, inclined, or specialized conveyors designed for extreme conditions, a well engineered handling system with increased belt life and minimal downtime delivers superior operational efficiency and lower total cost of ownership.

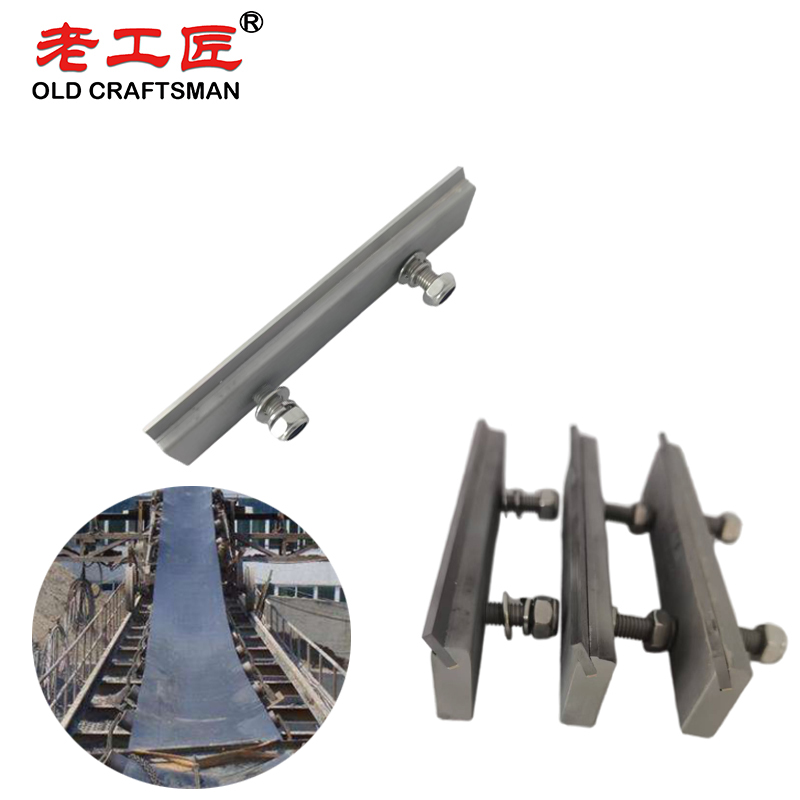

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding