Wear and Impact Solutions for Mining

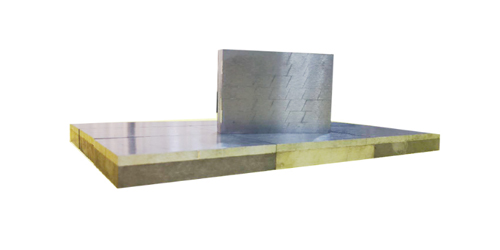

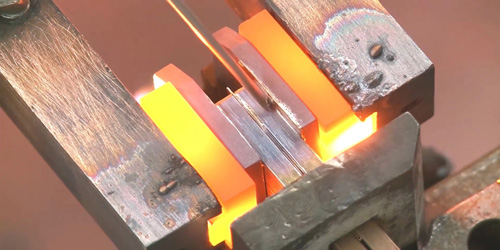

In heavy-duty industrial applications, the battle against wear is a constant one. From the rugged terrain of mining sites to the abrasive environments of mineral processing facilities, machinery faces significant challenges that require rugged solutions. Historically, wear-resistant steel, high-chromium cast iron, and high-aluminum ceramics have been the mainstays of wear protection. While each material has […]

Wear and Impact Solutions for Mining Read More »