Brazing vs. Welding

Catalogue

Introduction

In terms of joining metals collectively, brazing and welding are popular strategies utilized by professionals and DIY fans alike. Whilst both methods can bond metals, they vary in phrases of system, materials used, and application.

In this text, we will discover the discrepancies between brazing and welding, which include the advantages and boundaries of each method. We’re going to additionally offer some guidelines on the way to pick the right option for your unique task wishes.

Brazing vs. Welding: What’s the Difference?

Brazing and welding are techniques used to bond metals together, but they vary in some aspects:

Process: Brazing uses heat and a filler metal to bond metals collectively, while welding melts the base metals to create a joint.

Temperature: Brazing commonly uses lower temperatures than welding, making it ideal for joining different metals or metals with different melting points.

Materials: Brazing adopts a filler metal, copper or silver for instance, to create the bond, whilst welding the base metals to create the joint.

Strength: Welding typically produces a stronger bond than brazing, even though the latter can nonetheless create a robust joint.

Appearance: Brazing often brings an aesthetically appealing joint, as the filler metal can match the color of the base metals.

Now that we’ve covered the simple variations, take a closer look at brazing and welding and their respective benefits and boundaries.

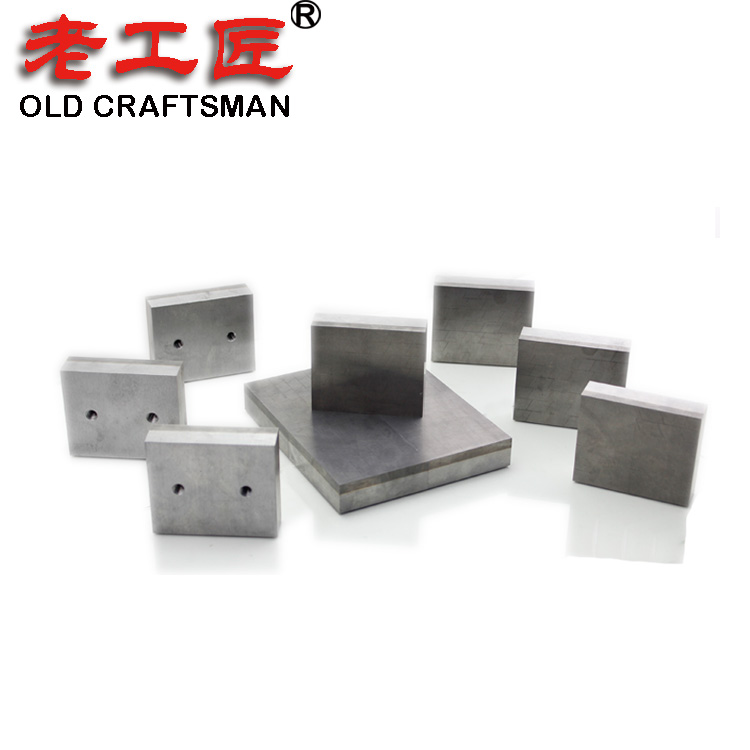

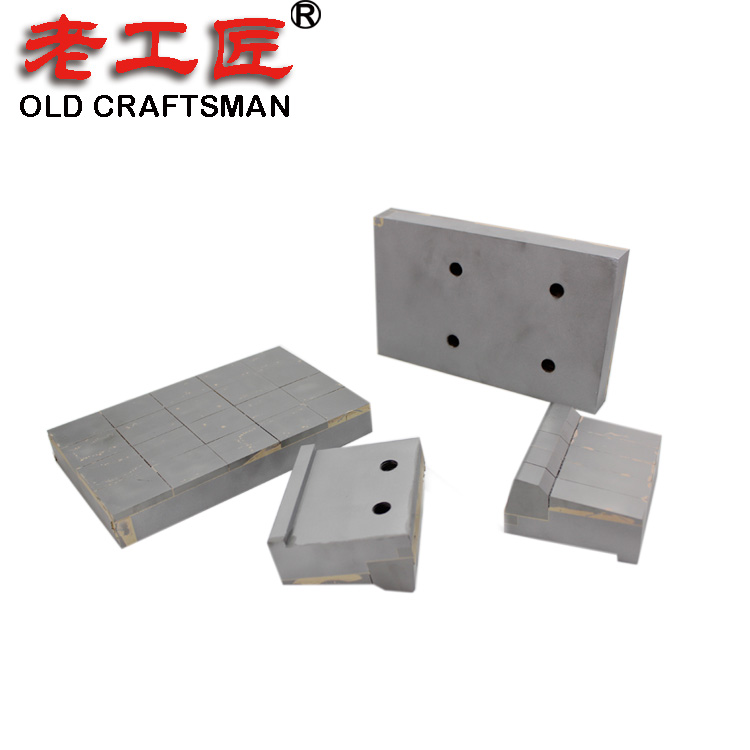

Brazing

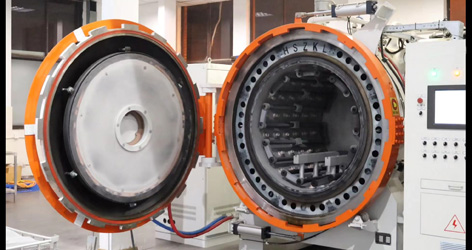

The principle of brazing is to adopt a brazing material with a lower melting point, and use a heating temperature higher than the melting point of the brazing material and lower than the melting point of the base material to melt the brazing material instead of the base material. The brazing material is liquefied to wet the base material, and under the capillary action of the brazing gap, it is automatically filled into the gap of the base material and forms a firm bond by mutual diffusion. Brazing causes less deformation and create a smooth joint, which is suitable for welding precise, complex components made of different materials, such as carbide tools. (Check → How to Braze Tungsten Carbide)

Benefits of Brazing

1. Can connect dissimilar metals

2. Lower temperature requirements

3. Creates a clean joint with minimal distortion

4. Filler metal can match the color of the base metals, creating an aesthetically pleasing appearance

Limitations of Brazing

1. Not suitable for high-stress applications

2. May not be as strong as a welded joint

3. Limited joint thickness

When to Use Brazing

Brazing is an incredible preference for bonding dissimilar metals, including tungsten carbide and stainless-steel, or those with different melting points. It can also create a nice and captivating joint, because the color of filler metallic is the same as the base metals. But, brazing might not be the fine option for high-strain programs or joints that require maximum strength. In these cases, welding can be a better preference.

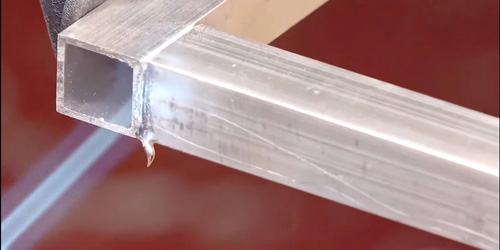

Welding

Welding is a process that involves melting the base metals to create a joint. The heat from the welding process melts the base metals, which then cool and solidify, creating a strong bond.

Benefits of Welding

1. Creates a very strong joint

2. Ideal for high-stress applications

3. Can join a wide range of materials and thicknesses

Limitations of Welding

1. Requires higher temperatures than brazing

2. May cause distortion or warping of the base metals

3. May require additional machining or finishing to achieve a smooth appearance

When to Use Welding

Welding is best for joining thick sections of metals or when a strong bond is required. It’s suitable for welding metals with different shapes and sizes, making it ideal for complex or irregularly shaped components. Welding is commonly used in construction, manufacturing, and automotive industries where strength and durability are essential. However, it can create a lot of heat and sparks, which can be dangerous. It can additionally result in distortion or warping of the base metals and may not be suitable for fragile or thin metals.

Conclusion

In short, brazing and welding are popular strategies used to join metals collectively, both with its distinct advantages and boundaries. Brazing is good for joining assorted metals or metals with different melting points, and can lead to an aesthetically desirable joint. Welding, then again, is good for high-strain applications and can connect an extensive range of materials at various thicknesses.

Next time when determining which choice to make, you should keep in mind the ultimate requirements and application of your project. By understanding the differences between brazing and welding, you can make a comprehensive choice and make certain the success of your project.

Featured products of ZZ Old Craftsman