High Pressure Grinding Rolls (HPGRs) are used in the mining and mineral processing industries to crush and grind ore into smaller particles. The process involves applying extremely high pressure (up to 300 MPa) to the feed material, which causes interparticle comminution. Due to the abrasive nature of ores and the high pressures involved, wear resistance is a critical factor in HPGR performance and longevity.

Why Tungsten Carbide Wear Plates Are Used in HPGRs:

- Exceptional Hardness & Wear Resistance

- Tungsten carbide (WC) is one of the hardest materials available (HV ~1500-2200), making it highly resistant to abrasion from hard minerals like quartz, iron ore, and diamonds.

- Compared to steel or chrome plating, tungsten carbide significantly extends the lifespan of HPGR components.

- High Compressive Strength

- HPGRs operate under extreme pressures, and tungsten carbide can withstand these forces without cracking or deforming.

- Its compressive strength (up to 6000 MPa) is much higher than steel or ceramic alternatives.

- Impact Resistance

- While being extremely hard, tungsten carbide also has good toughness (when combined with a cobalt or nickel binder), preventing chipping or spalling under repeated high pressure impacts.

- Corrosion & Chemical Resistance

- Unlike some steels, tungsten carbide is resistant to corrosion from moisture and certain chemicals present in ore processing.

- Improved Grinding Efficiency

- The smooth but durable surface of tungsten carbide wear plates ensures consistent grinding performance over time, reducing downtime for replacements.

- Less wear means tighter control over the particle size distribution of the output.

- Cost-Effectiveness Over Time

- Although tungsten carbide wear plates have a higher initial cost, their extended service life reduces maintenance costs and increases operational uptime, making them more economical in the long run.

Comparison with Alternatives:

- Hardened Steel/Chrome Plating – Wears out faster under high abrasion.

- Ceramics (e.g., alumina) – Hard but brittle, prone to cracking under high pressure.

- Polyurethane/Other Polymers – Not suitable for high pressure abrasive environments.

Conclusion:

Tungsten carbide is the optimal choice for HPGR wear plates because it combines extreme hardness, wear resistance, toughness, and pressure tolerance, ensuring long lasting performance in harsh grinding conditions. This reduces operational costs and improves efficiency in mineral processing.

High Pressure Grinding Rolls (HPGR) have become a proven technology for energy efficient comminution of hard and competent ores, including stainless steel bearing mineral ores containing chromium, nickel and other refractory minerals. Compared to conventional energy intensive ball mills or SAG mills, HPGR significantly reduces specific energy consumption while delivering superior grinding performance and finer product size distribution.

The core of HPGR’s advantages lies in the inter particle breakage mechanism under extremely high pressure (typically 100–250 N/mm²) applied between two counter rotating rolls. This high pressure grinding environment generates micro cracks throughout the particles, improving downstream liberation and overall production quality. Test results from numerous industrial operations consistently demonstrate 10–30 % lower energy requirements and increased throughput when replacing or complementing traditional grinding circuits.

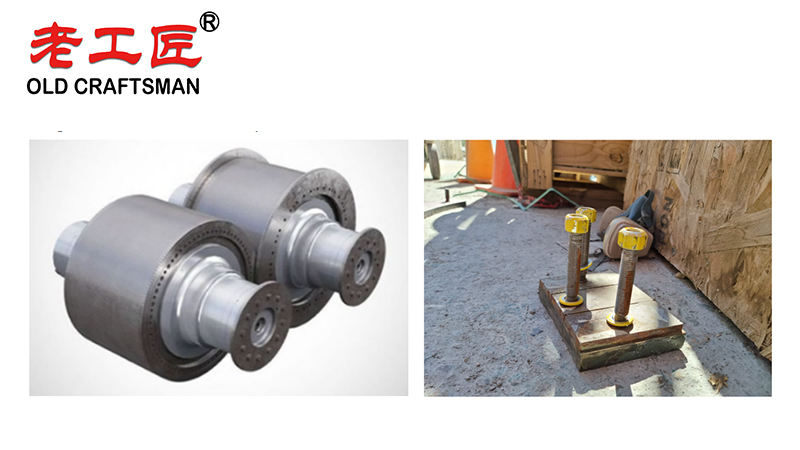

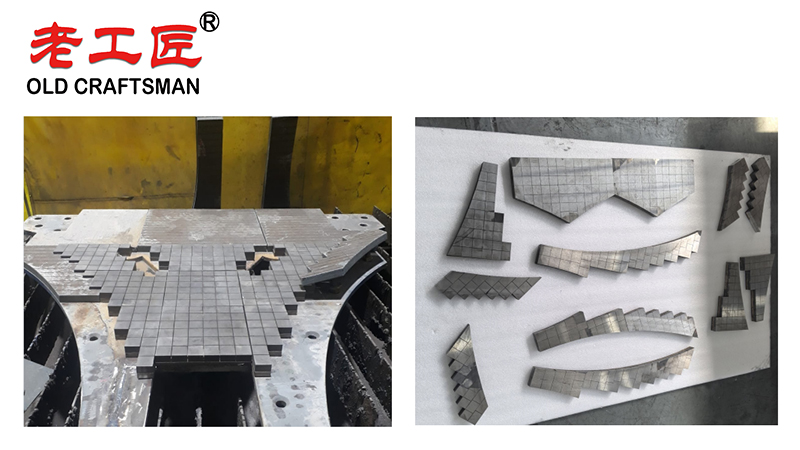

A critical factor for achieving optimal performance and long service life is the selection of wear resistant materials for the roll surface. Modern HPGR units are equipped with autoclave cured tungsten carbide studded wear plates or hexagonal wear resistant plates made of high quality tool steel composites. These surfaces are specifically engineered to withstand the abrasive nature and high temperatures generated during processing of tough stainless steel ores and associated hard minerals.

Proper feed size control (typically top size < 50–63 mm) and consistent mill feeding are essential to maintain stable operation and maximize the benefits of high pressure grinding. When material properties, roll speed, and specific press force are optimized together with advanced wear protection systems, HPGR technology delivers exceptional long term grinding performance, reduced maintenance downtime, and superior overall cost effectiveness in demanding mineral processing applications.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding