ZZ CRAFTSMAN’s HPGR Flange Wear Liner offers several key advantages that enhance the performance and longevity of High Pressure Grinding Rolls (HPGR) in mining and mineral processing applications. Here are the main benefits:

1. Superior Wear Resistance

- Made from high quality, abrasion resistant materials (such as advanced alloys or composite ceramics) to withstand extreme pressure and abrasive wear.

- Extends the service life of the HPGR, reducing downtime and replacement costs.

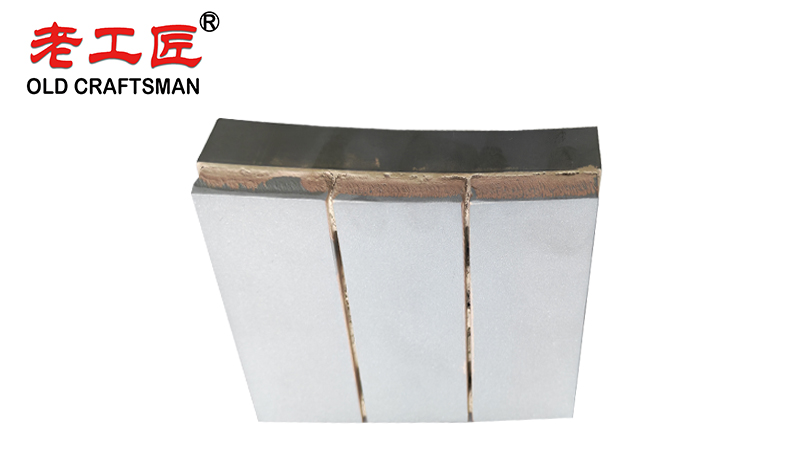

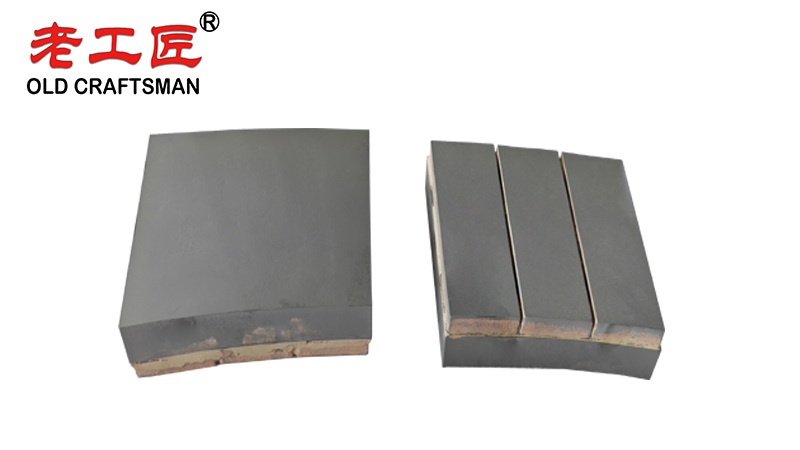

2. Enhanced Protection for Flange Areas

- Specifically designed to protect the flange (edge) of the HPGR rolls, which are highly susceptible to wear.

- Prevents premature roll damage, maintaining grinding efficiency and product quality.

3. Optimized Grinding Performance

- Maintains consistent roll geometry, ensuring uniform particle size distribution in the grinding process.

- Reduces energy consumption by minimizing slippage and improving material feed stability.

4. Easy Installation & Replacement

- Engineered for quick and secure installation, minimizing maintenance time.

- Modular designs allow for partial replacement instead of full roll changes, saving costs.

5. Customizable Solutions

- Available in various sizes, materials, and configurations to match different HPGR models and operational conditions.

- Can be tailored for specific ore types (e.g., hard rock or highly abrasive materials).

6. Cost-Effective Solution

- Reduces the frequency of roll replacements, lowering total ownership costs.

- Improves operational efficiency by reducing unplanned shutdowns.

7. Compatibility with Major HPGR Brands

- Designed to fit HPGRs from leading manufacturers like Metso, ThyssenKrupp, FLSmidth, and Köppern.

Conclusion

ZZ CRAFTSMAN’s HPGR Flange Wear Liner is a high performance solution that enhances durability, efficiency, and cost effectiveness in high-pressure grinding operations. Its robust design and wear resistant properties make it ideal for demanding mining and mineral processing environments.

HPGR Edge Blocks deliver an energy efficient, high quality solution for modern grinding processes, offering long term durability and exceptional resistance to extreme wear and high temperatures. By significantly reducing energy consumption and overall operational costs, they enable cost effective performance while simultaneously increasing production capacity. The integration of real time data monitoring supports continuous improvement initiatives, driving process improvements that enhance both productivity and quality. Ultimately, HPGR Edge Blocks contribute to reduced costs, higher efficiency (including lower energy use), and sustained improvements in operational efficiency and productivity making them the preferred choice for demanding high efficiency grinding applications such as total knee replacement component manufacturing and other precision industries.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding