To ensure your HPGR (High Pressure Grinding Rolls) equipment has far superior and longer lasting wear liners compared to traditional designs, you can adopt the old craftsman’s approach using tungsten carbide (WC). Here’s a step-by-step guide:

1. Select High-Quality Tungsten Carbide Material

- Use ultra-fine grain tungsten carbide (WC) with high cobalt (Co) binder (6-12%) for optimal wear resistance and toughness.

- Ensure the carbide has low porosity and high hardness (≥90 HRA).

- Consider functionally graded carbide (harder surface, tougher core) for extreme durability.

2. Optimize the Wear Liner Design

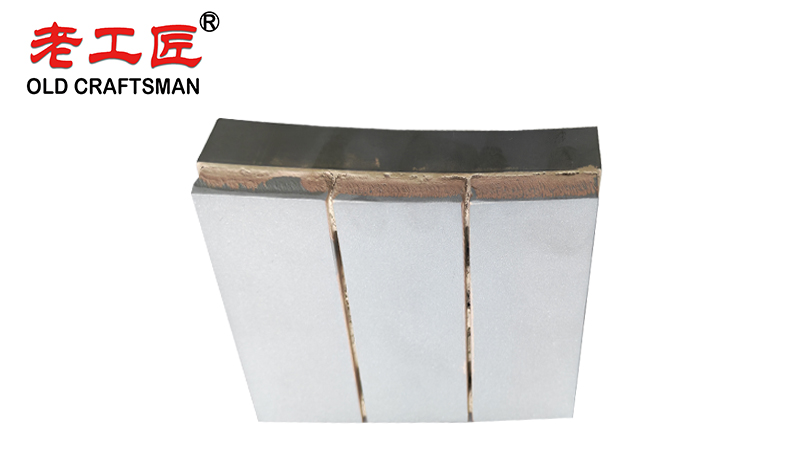

- Thickness: Increase liner thickness (≥50mm) for extended life.

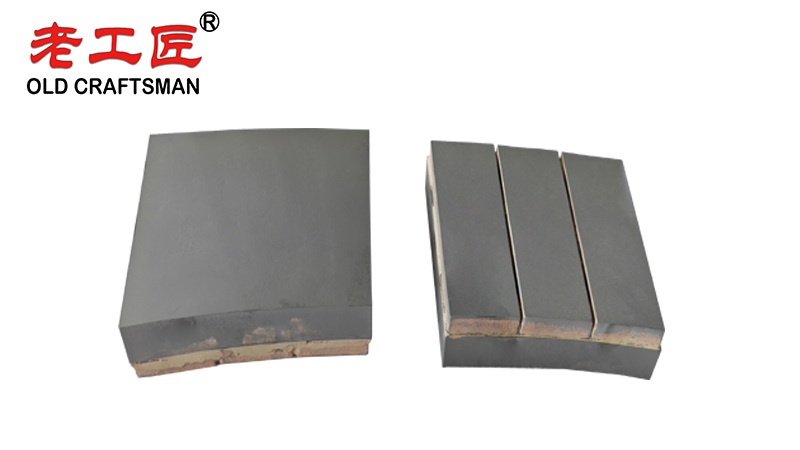

- Modular Segments: Use hexagonal or interlocking segments to distribute wear evenly.

- Surface Geometry: Implement chevron, studded, or grooved patterns to improve grinding efficiency and reduce slippage.

- Reinforced Backing: Use steel backed carbide liners for better shock absorption.

3. Advanced Manufacturing Techniques

- HIP (Hot Isostatic Pressing): Ensures dense, void free carbide for maximum durability.

- Braze or Mechanically Fix:

- For brazing, use high temperature silver or nickel based alloys.

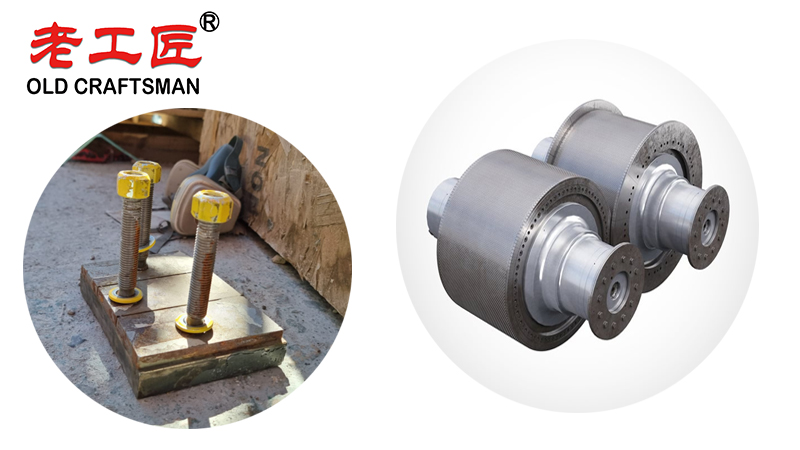

- For mechanical fixation, use dovetail or bolt-on designs for easy replacement.

- Precision Grinding: Ensure tight tolerances (±0.05mm) for seamless HPGR roll assembly.

4. Surface Treatment & Coatings

- Diamond-Like Carbon (DLC) Coating: Reduces friction and wear further.

- Laser Texturing: Creates micro-pockets to trap abrasive particles, reducing direct wear.

- Post-Sintering Heat Treatment: Enhances toughness by stress-relieving the carbide.

5. Proper Installation & Maintenance

- Torque Control: If bolted, use calibrated torque wrenches to avoid cracking.

- Regular Inspection: Check for chipping, cracks, or uneven wear every 500-1000 hours.

- Rotate Segments: Swap liner positions periodically to balance wear.

6. Operational Best Practices

- Avoid Metal Contamination: Use metal detectors to prevent tramp iron damage.

- Optimize Feed Size: Keep within HPGR manufacturer specs to reduce uneven wear.

- Controlled Pressure: Avoid excessive roll pressure that accelerates wear.

Why This Outperforms Standard Liners?

✔ 3-5x Longer Lifespan than standard high chrome or welded carbide liners.

✔ Lower Downtime due to modular, replaceable segments.

✔ Higher Grinding Efficiency due to optimized surface geometry.

By following these old school craftsmanship principles with modern tungsten carbide tech, your HPGR liners will last far longer while maintaining peak performance.

In the demanding field of high-performance grinding operations, HPGR carbide flanges made from tungsten carbide have emerged as a superior choice for processing stainless steels and other resistant materials. These components offer exceptional abrasion resistance and high strength, enabling them to withstand extreme high temperature grinding processes in ball mills or advanced grinding machines. Compared to traditional grinding wheels, tungsten carbide flanges deliver superior grinding performance, resulting in better surface finish and significantly extended life expectancy. This combination of durability and efficiency ensures high quality outcomes, longer operational life, and a wide range of applications, making them an ideal solution for industries seeking reliable, high performance grinding solutions.

In high-pressure grinding rolls (HPGR) used in the mining and cement industries, wear liners are exposed to extreme high temperatures and severe abrasive wear during the intense grinding process. To ensure optimal performance and significantly extend grinding wheel life expectancy and overall wear parts service life, manufacturers select high strength, abrasion resistant materials such as specially developed stainless steel grades or cemented carbide (tungsten carbide) with excellent resistance to high speed abrasive wear and a low coefficient of friction. These advanced wear resistant materials allow the components to live longer even under the harshest conditions, making them ideal for applications requiring maximum durability, whether in roll surfaces, cutting tools, or other critical wear parts subjected to continuous high speed, high load operation.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding