The most effective wear parts for an impact crusher depend on the application, material being crushed, and the crusher type (horizontal shaft impactor/HSI or vertical shaft impactor/VSI). However, the key wear parts that significantly impact performance and longevity are:

1. Blow Bars (HSI) / Impeller Shoes (VSI)

- Function: Directly strike and break the material.

- Best Material Choice:

- Martensitic Steel (e.g., Chrome Steel): Good for abrasive materials like limestone.

- Ceramic Inserts: Excellent for highly abrasive materials (e.g., granite, quartz).

- High-Chrome Iron (Hi-Cr): Best for hard and abrasive rocks (longest lifespan but more expensive).

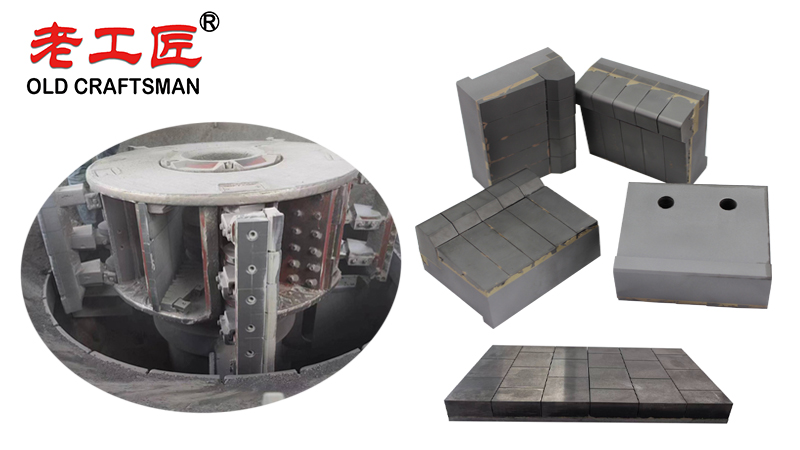

2. Impact Plates / Apron Liners

- Function: Absorb secondary impacts and protect the crusher housing.

- Best Material: High manganese steel or tungsten carbide for durability.

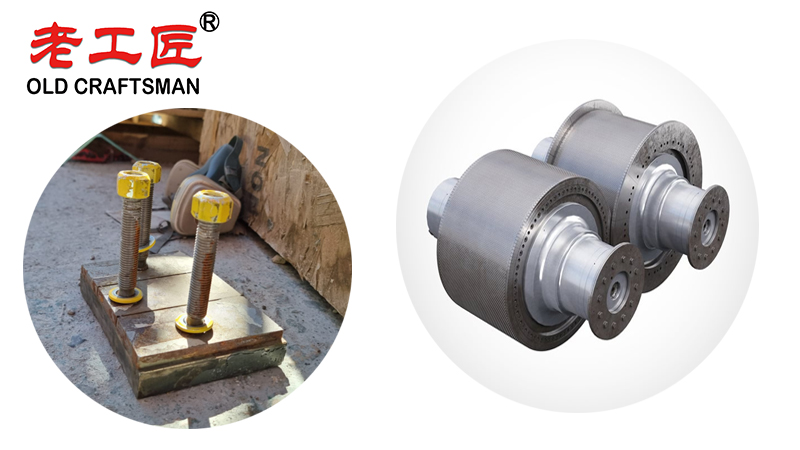

3. Rotor (HSI) / Rotor Tips (VSI)

- Function: The rotating component that holds blow bars or impeller shoes.

- Best Protection: Hard faced or carbide coated rotors for extended life in abrasive conditions.

4. Anvils & Wear Liners (VSI)

- Function: Provide crushing surfaces in VSI crushers.

- Best Material: Tungsten carbide or high chrome alloys for maximum wear resistance.

5. Side Liners / Curtains

- Function: Protect the crusher’s interior from wear.

- Best Choice: Replaceable manganese steel or composite liners.

Most Effective Wear Part?

- For HSI Crushers: Blow bars are the most critical they directly affect crushing efficiency and need frequent replacement.

- For VSI Crushers: Rotor tips & anvils are crucial due to high speed impacts.

Optimization Tips:

✔ Match material hardness to wear part composition.

✔ Rotate blow bars periodically to extend life.

✔ Monitor wear patterns to avoid rotor damage.

Mining carbide crusher hammers, often made from high quality tool steels with precise chemical compositions and controlled carbon content, offer superior performance in demanding industrial applications. These hammers incorporate alloying elements to achieve high strength, excellent tensile strengths, and remarkable work hardening properties. Compared to traditional carbon steel options, which provide a wide range of cost effectiveness, mining carbide variants excel in corrosion resistance and high temperature environments. By integrating resistant materials such as silicon carbide or aluminum oxide in composite designs, they deliver enhanced durability for cutting tooling and heavy duty crushing applications, including those involving abrasive ores. This combination ensures longer service life and reduced downtime in harsh mining operations.

For maximum efficiency, use high chrome or tungsten carbide wear parts in highly abrasive conditions.

Mining crusher hammers are essential wear resistant materials designed for high temperature environments and a wide range of industrial applications, including crushing abrasive ores and rocks. These components, often made from alloy steel or specialized steel alloys with key alloying elements like chromium and manganese, undergo advanced heat treatment processes to enhance their mechanical properties, such as superior abrasion resistance and toughness. The material properties allow the hammers to work harden during operation, where the steel hardens progressively under impact, extending service life. Cast iron variants are also used for cost effectiveness in less demanding scenarios. Similar principles apply to abrasion materials in brake pads, which prioritize heat dissipation and durability. Test methods, including hardness and impact testing, ensure quality. For specific applications or custom solutions in abrasion resistant materials, contact us today!

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding