When selecting wear plates for High Pressure Grinding Rolls (HPGR), tungsten carbide stands out as the superior choice compared to alternative materials. Here’s a comprehensive comparison:

Tungsten Carbide Advantages

- Exceptional Hardness (90-93 HRA):

- Highest wear resistance of all materials considered for HPGR applications

- Maintains hardness at elevated temperatures

- Superior Wear Resistance:

- Lasts 3-5 times longer than hardened steel alternatives

- Reduces downtime for replacements

- Compressive Strength:

- Ideal for the extreme pressures in HPGR operations (up to 300 MPa)

- Resists cracking under load

- Corrosion Resistance:

- Performs well in wet grinding applications

- Resists chemical attack from processed materials

Comparison with Other Materials

| Material | Hardness | Wear Life | Impact Resistance | Cost Efficiency |

|---|---|---|---|---|

| Tungsten Carbide | 90-93 HRA | ★★★★★ | ★★★☆☆ | ★★★★☆ |

| Hardened Steel | 58-62 HRC | ★★☆☆☆ | ★★★★★ | ★★☆☆☆ |

| Chrome White Iron | 62-67 HRC | ★★★☆☆ | ★★☆☆☆ | ★★★☆☆ |

| Ceramic Composites | 85-90 HRA | ★★★★☆ | ★☆☆☆☆ | ★★☆☆☆ |

Economic Considerations

While tungsten carbide has a higher initial cost, its extended service life typically results in:

- Lower total cost of ownership

- Reduced maintenance costs

- Increased operational uptime

- Better process consistency over time

Application-Specific Advantages

For HPGRs processing:

- Abrasive ores: Superior performance in iron, copper, and gold applications

- High-throughput operations: Maintains performance under continuous use

- Fine grinding applications: Provides consistent particle size distribution

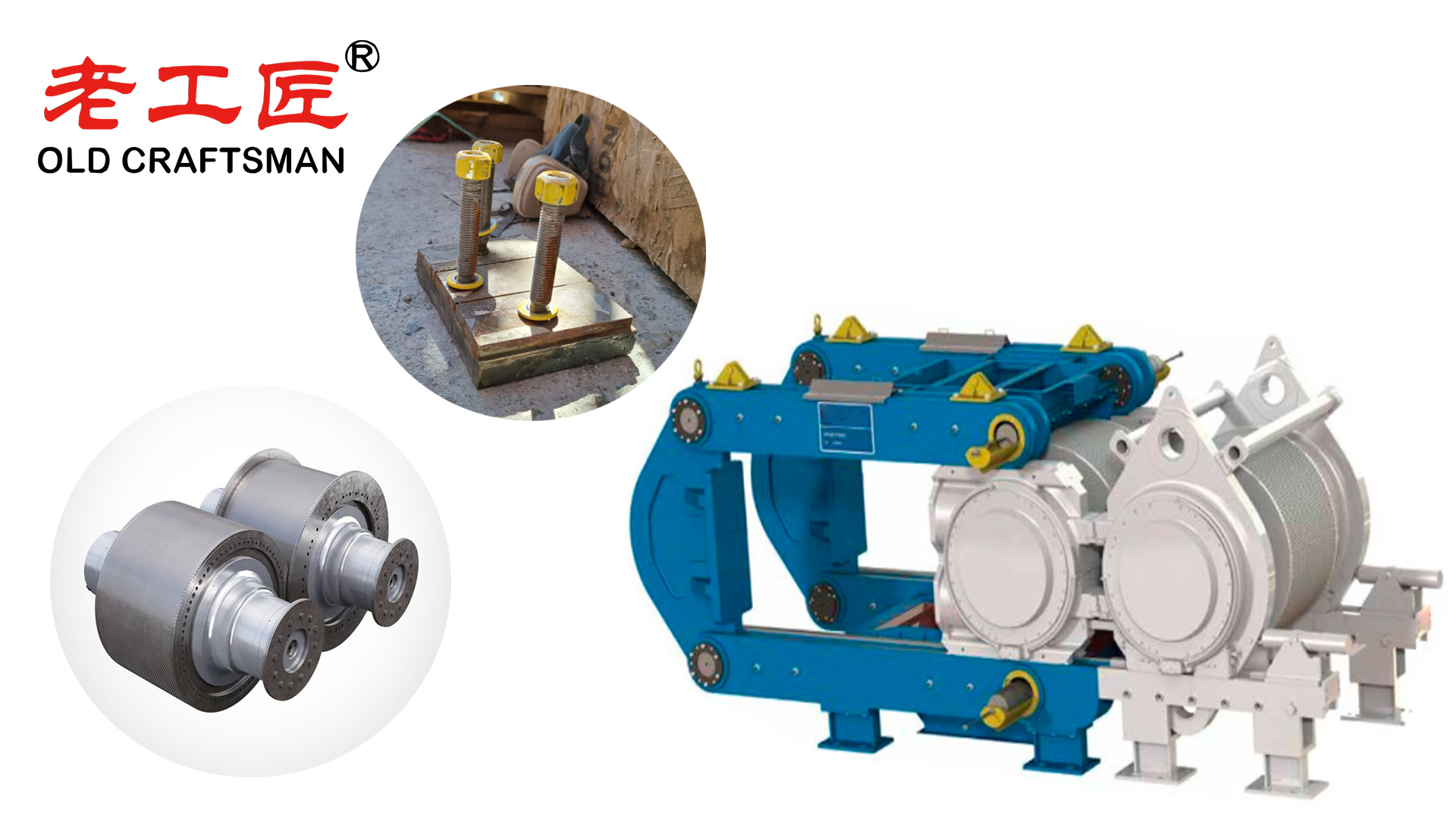

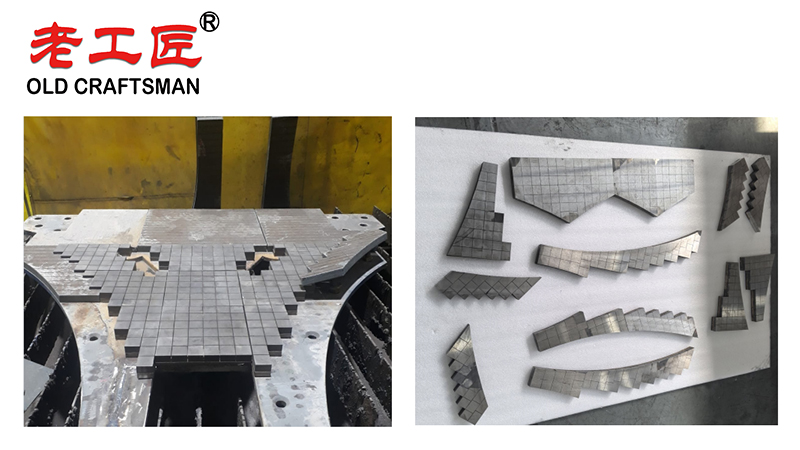

HPGR Carbide Cheek Plates are engineered for high performance in demanding industrial applications, offering exceptional mechanical properties at both room temperature and high temperatures. Made from a highly resistant alloy, these plates provide outstanding abrasion resistant capabilities and superior resistance to abrasive wear, making them ideal for harsh environments, including marine environments. Their high strength and long term durability ensure reduced maintenance and a wide range of uses, particularly in high speed operations where different types of wear are a constant challenge. Proper material selection of these high quality carbide cheek plates delivers unmatched resistance of a material to degradation, ensuring reliable performance even under the most severe conditions.

Conclusion

For most HPGR applications, tungsten carbide wear plates offer the best combination of wear resistance, operational longevity, and cost effectiveness. The material’s exceptional hardness and durability make it the preferred choice for operations prioritizing minimal downtime and maximum efficiency.

A successful tungsten carbide HPGR wear plate solution balances material science, engineering design, and operational practicality. Prioritize high-impact zones with tunsgten carbide, optimize installation for quick maintenance, and partner with experienced suppliers to ensure longevity in harsh mining environments.

HPGR cheek plates operate in one of the most severe high wear and abrasive wear environments in the mining and cement industries, where extremely high pressure and sliding contact generate intense mechanical stress and surface degradation. To ensure long service life and cost-effective operation, these critical components are protected by high strength, abrasion resistant and scratch resistant inserts made from advanced wear resistant materials with outstanding mechanical properties and a very high melting point. The preferred solution is typically high performance drill bits and cutting tools produced from premium stainless steel grades or cemented carbides that exhibit exceptionally low coefficient of friction, superior resistance to abrasive wear, and consistently high quality throughout their lifespan. By selecting the optimal raw material and applying precise manufacturing processes, manufacturers deliver wear solutions that dramatically extend maintenance intervals, reduce downtime, and provide the best total cost of ownership for demanding industrial applications.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding