Tungsten carbide wear plates are widely used in High Pressure Grinding Roll (HPGR) operations to minimize downtime and enhance operational efficiency. Here’s how they contribute to reducing downtime:

1. Exceptional Wear Resistance

- Tungsten carbide is one of the hardest materials available (HV 1500-2000), significantly outperforming steel and chrome carbide in abrasive environments.

- In HPGR applications, where high pressure crushing generates extreme wear, WC wear plates last 3-5 times longer than conventional materials, reducing the frequency of replacements.

2. Reduced Maintenance Intervals

- Since WC wear plates degrade much slower than steel or composite alternatives, maintenance shutdowns for plate replacement are less frequent.

- Fewer replacements mean longer continuous operation and less unplanned downtime.

3. Improved Operational Efficiency

- The superior hardness of tungsten carbide maintains a smoother working surface for longer, ensuring consistent grinding performance.

- This prevents premature roll damage and avoids efficiency losses that would otherwise require early intervention.

4. Protection Against Corrosion & Impact

- WC wear plates resist not only abrasion but also chemical corrosion from processed ores and moisture.

- Their toughness helps withstand impact loads, reducing cracks or spalling that could lead to unexpected failures.

5. Cost-Effectiveness Over Time

- Although WC plates have a higher upfront cost, their extended lifespan reduces total cost of ownership (TCO) by minimizing labor, replacement part costs, and production losses from downtime.

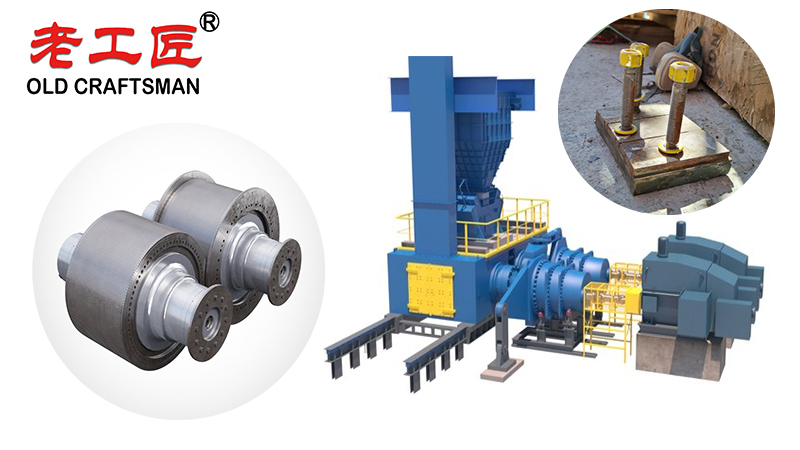

6. Compatibility with HPGR Design

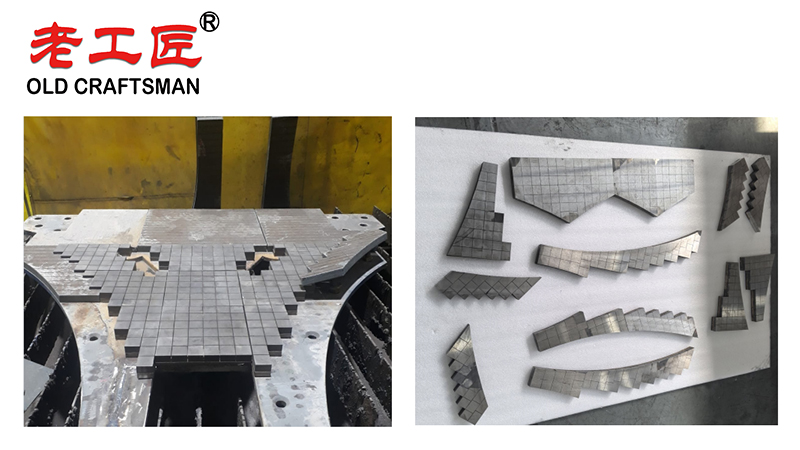

- WC wear plates can be custom designed to fit HPGR roll surfaces, cheek plates, or feed chutes, ensuring optimal protection in the most wear-prone zones.

- Some designs use tungsten carbide tiles embedded in a steel matrix for a balance of toughness and wear resistance.

Conclusion

By integrating tungsten carbide wear plates into HPGR systems, mining and mineral processing operations achieve:

✅ Longer service life (reduced replacement frequency)

✅ Fewer unplanned shutdowns (higher availability)

✅ Consistent grinding performance (better product quality)

✅ Lower long-term maintenance costs

In the demanding industrial applications of high pressure grinding rolls (HPGR), cheek plates serve as critical wear plates that prevent material bypass and mitigate abrasive wear on the roll edges. Mechanical engineers often select high temperature resistant materials, such as tungsten carbide composites or chromium rich alloys with complex carbides, to enhance abrasion resistance and high strength mechanical properties. These materials exhibit superior resistance of a material to abrasive wear a primary type of wear in HPGR operations while offering good corrosion resistance and a low coefficient of friction to minimize energy losses. High performance cheek plates, designed for a wide range of ore conditions, require regular maintenance to sustain optimal functionality, including timely inspections and replacements that help control maintenance expenses, repair costs, and overall maintenance budget. By prioritizing such proactive types of maintenance, operators can achieve extended service life and reduced downtime in these high wear environments.

This makes tunsgten carbide wear plates a critical component in maximizing HPGR uptime and productivity in abrasive ore processing applications.

A successful tungsten carbide HPGR wear plate solution balances material science, engineering design, and operational practicality. Prioritize high impact zones with tunsgten carbide, optimize installation for quick maintenance, and partner with experienced suppliers to ensure longevity in harsh mining environments.

In high pressure grinding rolls (HPGR), wear plates and tungsten carbide wear parts operate under extreme abrasive wear conditions and high temperatures for extended periods of time. To ensure long service life, high strength, excellent abrasion resistance, and superior mechanical properties are essential. The most cost effective solutions combine a wide range of high quality wear resistant materials, with tool steel bases or castings matrix embedded with tungsten carbide inserts being the industry standard. These advanced materials significantly reduce the coefficient of friction on the roll surface, minimize adhesive and abrasive wear mechanisms, and deliver substantially lower operating costs compared to conventional welded hardfacings. By implementing proper maintenance programs focused on regular inspection and timely replacement of worn components, operators can further decrease overall maintenance and repair costs, avoid unexpected downtime, and incur lower total maintenance expenses throughout the equipment lifecycle.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding