Tungsten carbide (WC) wear plates play a critical role in extending the service life of High-Pressure Grinding Rolls (HPGRs), which are widely used in the mining and mineral processing industry for efficient comminution of ores. Here’s how they contribute:

1. Exceptional Wear Resistance

- Tungsten carbide is one of the hardest materials available (HV ~1500-2500), making it highly resistant to abrasion from hard minerals.

- WC wear plates protect the HPGR roll surfaces from rapid degradation caused by high-stress grinding, significantly reducing downtime for maintenance.

2. Enhanced Durability in High-Pressure Conditions

- HPGRs operate under extreme compressive forces (50-300 MPa). WC’s high compressive strength (up to 6000 MPa) ensures structural integrity under these conditions.

- Unlike softer materials, WC does not deform or crack easily, maintaining roll geometry for consistent grinding performance.

3. Corrosion and Impact Resistance

- WC is chemically inert, resisting corrosion from moist or acidic ore environments.

- Its toughness (compared to ceramics) helps withstand impact loads from feed material fluctuations.

4. Improved Grinding Efficiency & Cost Savings

- By maintaining a stable roll surface profile, WC wear plates ensure consistent particle size reduction and energy efficiency.

- Reduced wear means fewer roll replacements, lowering operational costs and increasing machine availability.

5. Application Methods

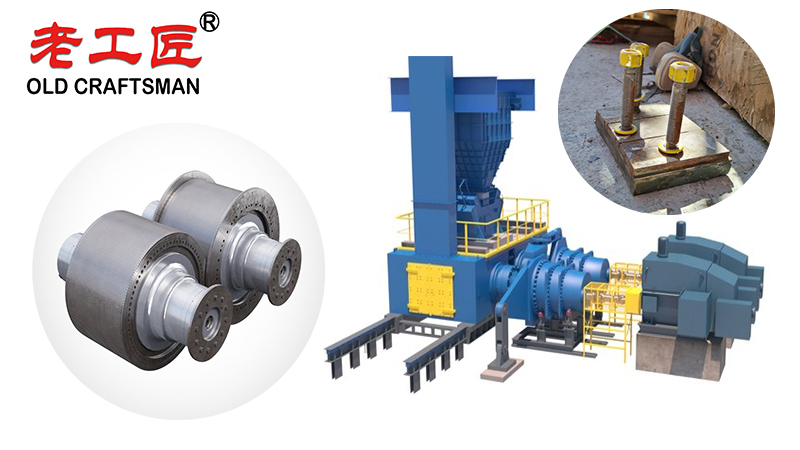

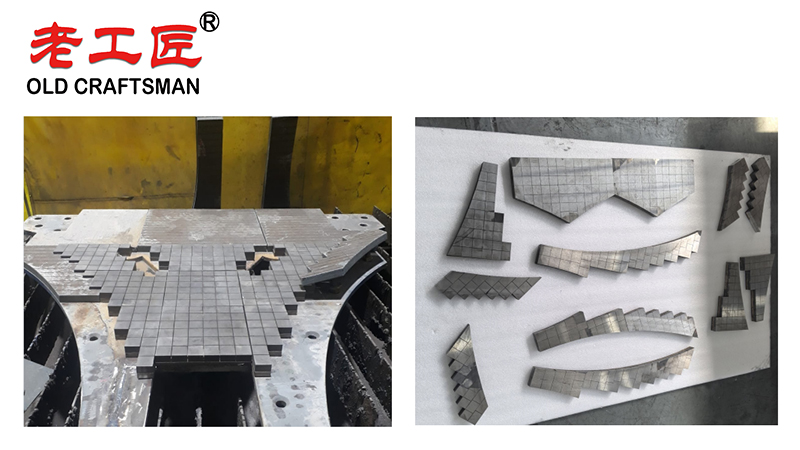

- Cladding/Welding: WC plates are often welded onto roll surfaces in a mosaic pattern to optimize coverage.

- Composite Rolls: Some HPGRs use WC-reinforced rolls, where a WC layer is fused onto a ductile core (e.g., steel) for a balance of hardness and toughness.

Industries Benefiting from WC in HPGRs

- Mining (iron, gold, diamond, copper ores)

- Cement & slag processing

- Industrial minerals (limestone, phosphate)

In mineral processing plants, particularly those handling iron ore, crushing and grinding are essential stages to reduce raw materials to the required particle size for liberating the valuable mineral from gangue. High-pressure grinding rolls (HPGR) are increasingly used for efficient comminution, often featuring wear plates or studded surfaces made from high-quality wear-resistant materials such as tungsten carbide to combat various types of wear, including abrasion, impact, and corrosion caused by mechanical action on abrasive ores. These wear-resistant materials enhance the mechanical properties of the equipment, extending service life where wear occurs under intense physical and chemical conditions. Compared to traditional ball mills, HPGR technology minimizes energy consumption and media wear while producing microcracks that facilitate downstream processes. After achieving optimal particle size reduction, separation techniques exploit differences in physical and chemical properties: magnetic separation is commonly applied for ferromagnetic iron ores like magnetite, gravity separation for density-based recovery, and froth flotation for finer particles or associated sulfides, ultimately concentrating the valuable mineral for high-quality output.

Conclusion

Tungsten carbide wear plates are a key innovation in HPGR technology, drastically improving service life, reducing maintenance costs, and ensuring operational efficiency in harsh grinding environments. Their adoption is critical for modern, high-throughput mineral processing plants.

A successful tungsten carbide HPGR wear plate solution balances material science, engineering design, and operational practicality. Prioritize high-impact zones with tunsgten carbide, optimize installation for quick maintenance, and partner with experienced suppliers to ensure longevity in harsh mining environments.

High Pressure Grinding Rolls (HPGR) have become a critical technology in modern mineral processing, particularly for iron ore and other valuable minerals, due to their ability to deliver superior energy efficiency and finer particle size reduction compared to conventional ball mills. The core of HPGR performance lies in the wear parts—specifically the wear plates and roll surfaces—which are exposed to extreme high pressure, intense abrasive wear, and occasionally high temperature environments.

To achieve acceptable service lives under these severe conditions, the industry relies heavily on advanced wear-resistant materials. Among them, high-strength tungsten carbide (often embedded in a tough metal matrix as studs or hexagonal tiles) remains the gold standard due to its outstanding combination of hardness, mechanical properties, and low coefficient of friction when properly designed. These tungsten carbide wear protection systems significantly reduce surface wear, minimize downtime, and maintain consistent grinding performance over extended industrial applications.

Ongoing research continues to focus on optimizing matrix compositions, stud patterns, and edge protection to further extend service life while balancing cost and performance in the harshest high-wear mineral processing operations.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding