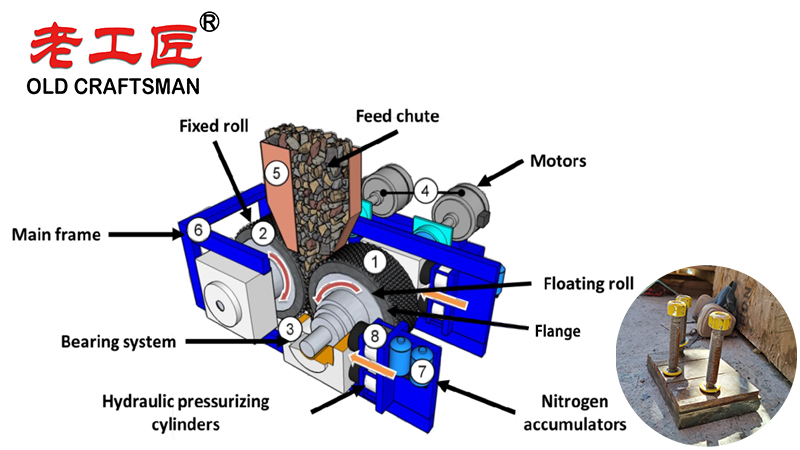

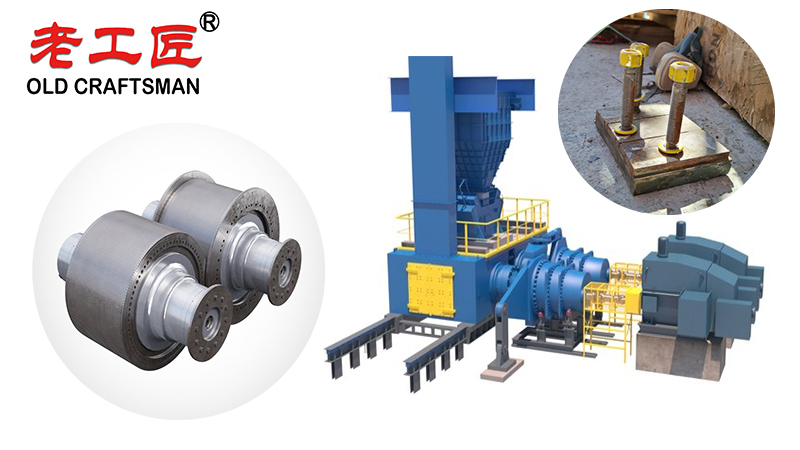

Introduction to HPGR Technology

High Pressure Grinding Rolls (HPGRs) have become increasingly important in mineral processing due to their energy efficiency and ability to produce fine particles with micro-cracks that improve downstream liberation. However, wear protection remains a critical challenge in HPGR operation.

Tungsten Carbide Wear Plate Advantages

Advanced tungsten carbide (WC) wear plates offer significant performance benefits:

- Exceptional Hardness: 85-93 HRA provides superior wear resistance compared to conventional materials

- High Compressive Strength: Ideal for the extreme pressures in HPGR applications (up to 300 MPa)

- Impact Resistance: WC-cobalt composites absorb operational shocks effectively

- Long Service Life: Typically 2-3 times longer than hardened steel alternatives

Optimization Strategies

Material Composition Optimization

- Grain Size Control: Nano-grained tungsten carbide (200-500nm) provides optimal hardness toughness balance

- Cobalt Content Adjustment: 6-12% cobalt binder for different operational conditions

- Additive Enhancement: VC or Cr3C2 grain growth inhibitors improve high temperature stability

Surface Engineering

- Pattern Design: Hexagonal, chevron, or custom patterns to optimize material flow

- Surface Texturing: Micro-grooves to reduce slippage and improve throughput

- Gradient Interfaces: Gradual hardness transitions to reduce spalling risk

Operational Integration

- Precision Mounting Systems: Ensure uniform pressure distribution

- Thermal Management: Integrated cooling channels for temperature control

- Wear Monitoring: Embedded sensors for real-time wear tracking

Performance Outcomes

Implementing advanced WC wear plates typically results in:

- 30-50% reduction in specific wear rates

- 15-25% improvement in energy efficiency

- 20-40% increase in operational uptime

- More consistent product size distribution

Maintenance Considerations

- Proper break-in procedures (gradual pressure ramping)

- Regular visual inspections and laser profiling

- Planned replacement before catastrophic failure occurs

- Proper handling to avoid pre-service damage

Future Developments

Emerging innovations include:

- Functionally graded tungsten carbide plates

- Self-lubricating WC composites

- Smart wear plates with integrated IoT sensors

- Additive-manufactured custom geometries

HPGR carbide wear plates, typically featuring tungsten carbide studs or surfaces, are high performance abrasion resistant materials designed for demanding industrial applications such as mining and mineral processing. These plates offer exceptional high strength and mechanical properties, providing superior resistance to abrasive wear and types of wear commonly encountered in high pressure environments. Tungsten carbide’s outstanding hardness and low coefficient of friction contribute to extending the service life and operational life of equipment over a long-term period of time, even under high temperatures where many materials lose performance. By significantly enhancing the resistance of a material to wear, these high performance solutions help prolong equipment durability and reduce downtime. For more details on our products and services, including frequently asked questions about abrasion resistant options, please contact our customer service team.

By implementing these advanced tungsten carbide wear plate solutions, mining operations can significantly improve HPGR performance while reducing total cost of ownership through extended service life and improved operational efficiency.

High Pressure Grinding Rolls (HPGR) cheek plates operating under high temperature and extreme abrasive wear conditions demand the ultimate in wear resistant materials. Tungsten carbide studded or solid cheek plates have become the cutting edge solution across a wide range of industrial applications, delivering exceptional high strength, low coefficient of friction, and dramatically extended service life compared to conventional stainless steel or hard faced alternatives.

Through an advanced manufacturing process that ensures precise material properties and optimal surface roughness, these wear parts provide superior protection for the roll surface in high pressure grinding environments. The result is reduced maintenance downtime, consistent product quality, and lower overall operating costs even when processing a large number of the most challenging ores and minerals.

Our commitment to high quality and responsive customer service means every set of HPGR cheek plates is engineered to meet the specific demands of your operation, keeping your high pressure grinding rolls performing at peak efficiency under the harshest conditions.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding