Tungsten carbide scrapers outperform traditional belt cleaners (often made from polyurethane or steel) due to several key advantages:

1. Superior Hardness & Wear Resistance

- Tungsten carbide (WC) is one of the hardest materials available (rated ~9 on the Mohs scale), far exceeding polyurethane or plain steel.

- It resists abrasion from sharp or heavy materials (e.g., coal, ore, gravel), extending service life significantly.

2. Effective Cleaning in Harsh Conditions

- Maintains a sharp edge even under high load, high speed conveyor operations.

- Resists degradation from moisture, chemicals, and extreme temperatures.

3. Reduced Belt Damage

- Unlike steel scrapers, which can gouge belts, tungsten carbide blades provide a cleaner, more controlled scrape.

- Minimizes belt wear, lowering long term maintenance costs.

4. Lower Maintenance & Cost Efficiency

- Lasts 3–5 times longer than polyurethane or steel alternatives, reducing replacement frequency.

- Fewer downtime interruptions for cleaner changes.

5. Self-Sharpening Properties

- Some tungsten carbide scrapers wear in a way that maintains an optimal cleaning edge over time.

6. Better Performance for Sticky or Wet Materials

- Prevents material buildup (carryback) more effectively than softer cleaners, especially in mining, cement, and aggregate industries.

Conclusion:

Tungsten carbide scrapers are the preferred choice for heavy duty applications where durability, efficiency, and belt protection are critical. While they may have a higher upfront cost, their longevity and performance lead to lower total cost of ownership compared to traditional belt cleaners.

Zhuzhou Old Craftsman Precision Alloy Co.,Ltd. a professional Chinese manufacturer of tungsten carbide products. Our main products are tungsten carbide blanks, precision products and brazing mining wear products.

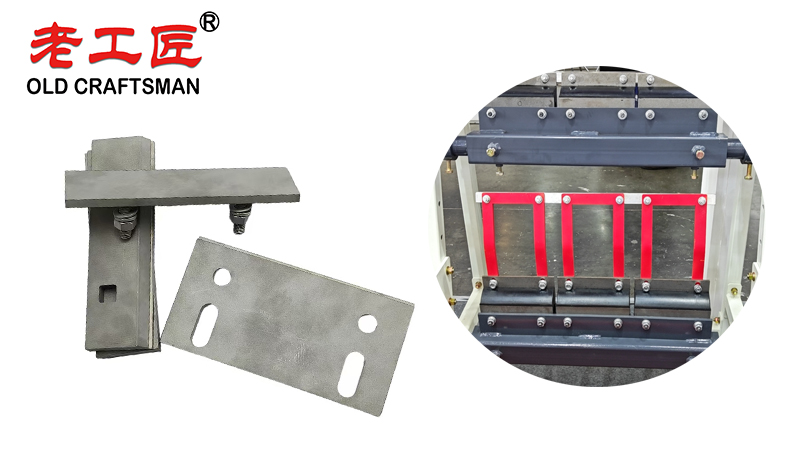

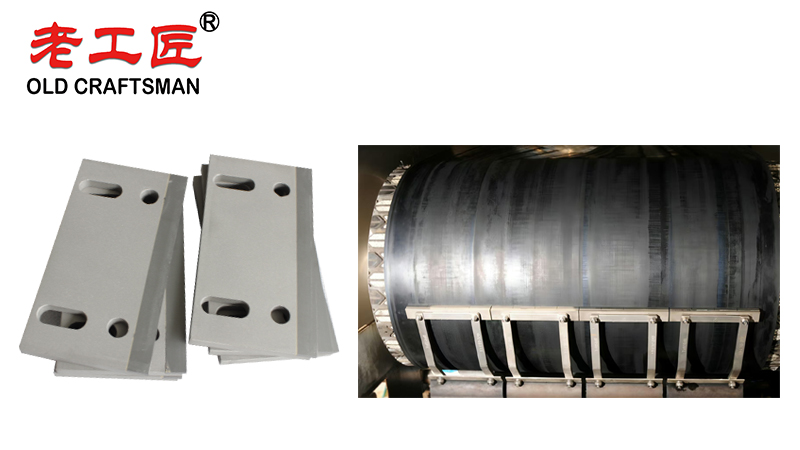

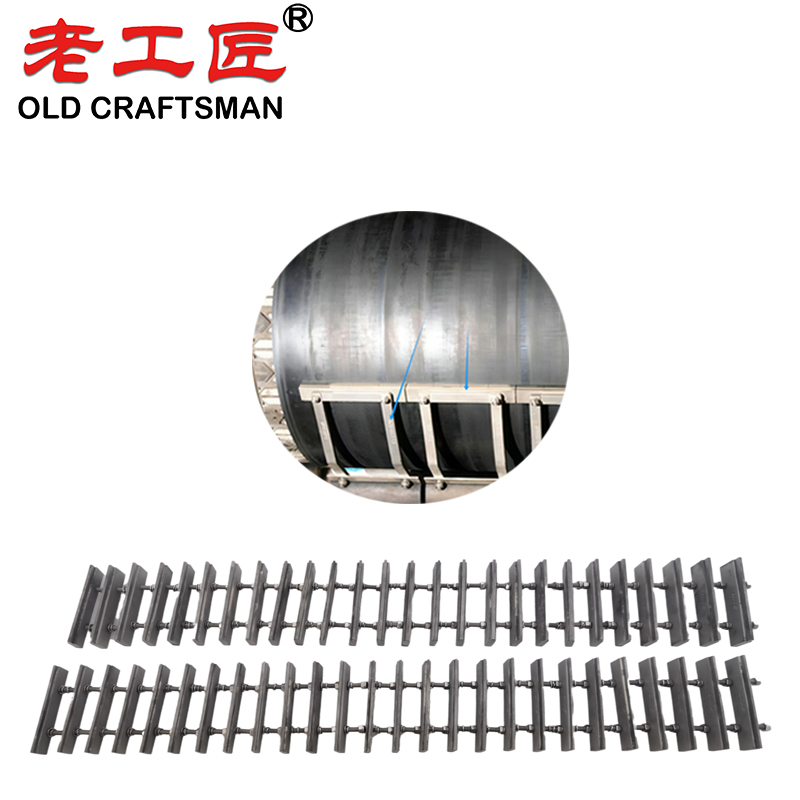

High-quality wear resistant belt scrapers for mining conveyor systems are specifically designed with premium tungsten carbide cutting tools and wear parts to handle extreme high wear and high temperature environments. These high performance conveyor belt scrapers effectively remove stubborn materials while protecting the conveyor belt, ensuring longer service life and significantly reduced downtime. Manufactured to the highest industry standards using durable tungsten carbide inserts brazed onto robust mild steel bodies, our wear solutions deliver exceptional wear life and outstanding performance in the toughest cutting applications and heavy duty mining operations.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding