Tungsten carbide conveyor belt scrapers are essential components in material handling systems, designed to efficiently clean conveyor belts and maintain optimal system performance. This guide covers everything you need to know about these durable, high performance scrapers.

What Are Tungsten Carbide Conveyor Belt Scrapers?

- Heavy-duty cleaning blades made from tungsten carbide material

- Designed to remove sticky, wet or dry material from conveyor belts

- Mounted at strategic points along the conveyor system (typically at the head pulley)

- Available in various configurations for different applications

Benefits of Tungsten Carbide Scrapers

- Exceptional Wear Resistance – Last up to 10 times longer than standard polyurethane scrapers

- Improved Cleaning Efficiency – Maintain consistent cleaning performance throughout their lifespan

- Reduced Maintenance Costs – Fewer changeouts required compared to other materials

- Corrosion Resistance – Ideal for wet or chemically aggressive environments

- High Temperature Tolerance – Perform well in both hot and cold applications

Types of Tungsten Carbide Scrapers

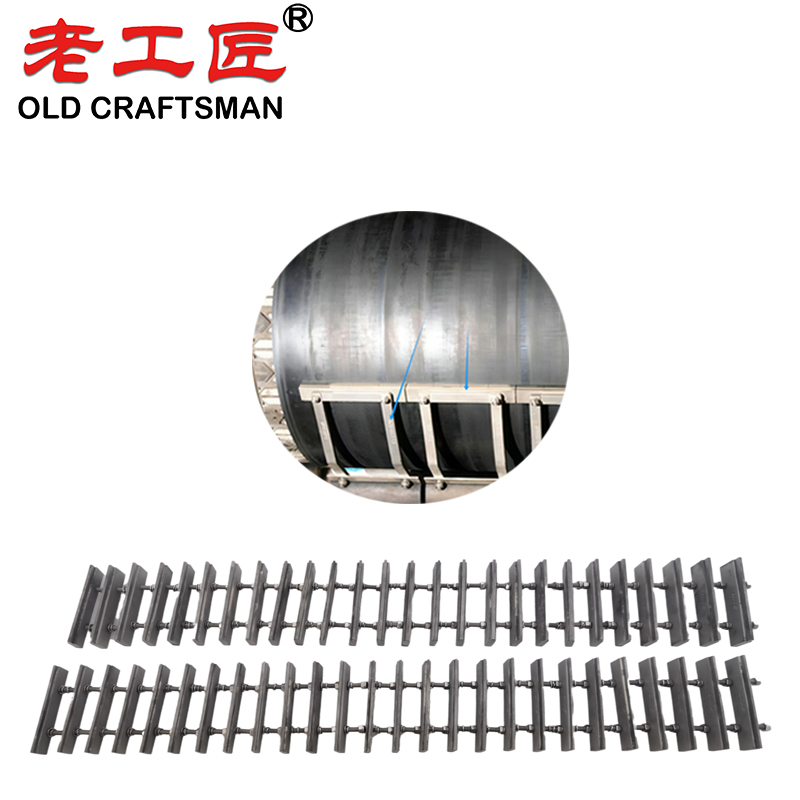

- Primary Scrapers: First line of defense, removing bulk material

- Secondary Scrapers: Fine cleaning after the primary scraper

- Pre-Cleaners: Initial material removal before primary scrapers

- Specialty Designs: Custom shapes for specific applications or belt types

Key Applications

- Mining and mineral processing

- Cement and aggregate plants

- Power generation (coal handling)

- Food processing

- Recycling facilities

- Wood and paper products

- Chemical processing

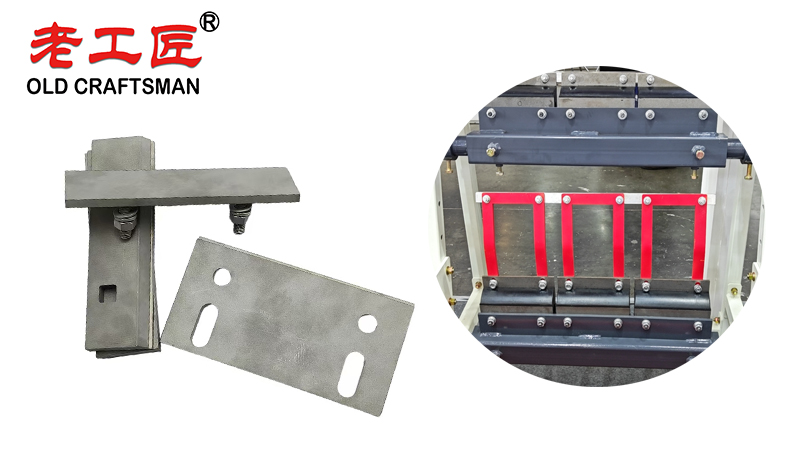

Installation Considerations

- Mounting Angle: Typically 30-45 degrees to the belt surface

- Contact Pressure: Must be properly adjusted to balance cleaning effectiveness with belt wear

- Positioning: Usually installed at the discharge point where material tends to stick

- Hardware: Requires sturdy mounting brackets and tensioning systems

Maintenance Best Practices

- Regularly inspect for wear (check for grooves or uneven wear patterns)

- Monitor belt condition for signs of excessive wear

- Keep mounting hardware tight and properly adjusted

- Clean accumulation areas to prevent material buildup

- Replace scrapers before they become completely worn

Cost Considerations

While tungsten carbide scrapers have a higher upfront cost than alternatives, their extended service life typically results in:

- Lower total cost of ownership

- Reduced downtime for changes

- Less frequent purchases

- Lower labor costs for maintenance

Selecting the Right Scraper

Consider these factors when choosing:

- Belt type and speed

- Material characteristics (abrasiveness, moisture content)

- Operating environment (temperature, chemicals)

- Conveyor configuration

- Cleaning requirements

Material handling systems play a crucial role in modern industries, enabling the efficient moving of materials across assembly lines and warehouses. Conveyor systems, including roller conveyors and mining conveyor belt scraper handling systems, are widely used for transporting a wide range of bulk materials or packaged goods. These automated systems ensure smooth loading and unloading processes while minimizing product damage and optimizing floor space.

Depending on the type of material whether lightweight items or heavy bulk loads in high temperature environments different conveyor solutions are selected. Belt conveyors excel when the belt moves continuously to transport items over long distances, while roller conveyors are ideal for pallet jacks and heavier loads.

By implementing cost effective conveyor systems, companies achieve improved efficiency, increased productivity, and long-term reliability. Overall, understanding how a conveyor system works allows businesses to choose the right equipment for their specific material handling needs.

Conclusion

Tungsten carbide conveyor belt scrapers offer superior performance and longevity for demanding material handling applications. By selecting the appropriate design and maintaining them properly, operations can achieve cleaner belts, reduced carryback, and lower maintenance costs over the long term.

Our advanced mining conveyor belt scraper systems are specifically designed for high temperature environments and bulk materials handling, including highly abrasive substances such as ore, coal, and aggregates. Featuring exceptional abrasion resistance and high strength construction, these scrapers ensure long-term reliability even under the toughest conditions, effectively removing sticky and fine materials from the belt to prevent carryback, reduce spillage, and extend belt life.

Integrated into comprehensive material handling processes, our solutions cover a wide range of equipment: from pallet racks and cost-effective pallet jacks for warehouse and manufacturing industries, to automated guided vehicles (AGV) that streamline loading and unloading operations on the assembly line. By optimizing the ability to transport material safely and quickly, the entire system significantly improves efficiency and delivers increased productivity while remaining highly cost effective over the long term.

Whether you need robust primary or secondary scrapers for mining conveyors or a complete automated material handling solution, our high-performance systems keep your operations running smoother, cleaner, and more profitably.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding