Tungsten carbide (WC) is widely regarded as the premier material for High Pressure Grinding Roll (HPGR) wear plates due to its exceptional durability and wear resistance. Here’s a breakdown of its key advantages:

1. Extreme Hardness & Wear Resistance

- Tungsten carbide has a Vickers hardness of 1,500–2,400 HV, far exceeding hardened steel (~800 HV) and even some ceramics.

- This hardness minimizes abrasive wear from ore particles, significantly extending service life compared to conventional materials.

2. High Compressive Strength

- WC can withstand compressive stresses exceeding 6,000 MPa, making it ideal for HPGRs, which operate under extreme pressures (50–300 MPa).

- Unlike steel, which can deform under load, tungsten carbide maintains structural integrity, reducing maintenance downtime.

3. Superior Fracture Toughness (Compared to Ceramics)

- While WC is brittle compared to metals, modern cobalt-bonded tungsten carbide grades (e.g., WC-Co) offer improved toughness (up to 20 MPa√m), resisting cracking under cyclic HPGR loading.

4. Corrosion & Oxidation Resistance

- WC-Co grades resist chemical wear from moist or acidic ores, unlike steel, which can corrode or spall.

- Protective coatings (e.g., CVD/PVD) can further enhance corrosion resistance in harsh environments.

5. Economic Long-Term Benefits

- Although initial costs are higher than steel, WC wear plates last 3–10x longer, reducing replacement frequency and downtime.

- Lower total cost of ownership (TCO) due to reduced labor and machine stoppages.

Comparison to Alternatives

| Material | Hardness (HV) | Compressive Strength (MPa) | Wear Life (Relative to Steel) |

|---|---|---|---|

| Tungsten Carbide | 1,500–2,400 | >6,000 | 3–10x |

| Hardened Steel | 600–900 | 2,000–3,000 | 1x (Baseline) |

| Ceramics (Al₂O₃) | 1,500–2,000 | 3,000–4,000 | 2–5x (but brittle) |

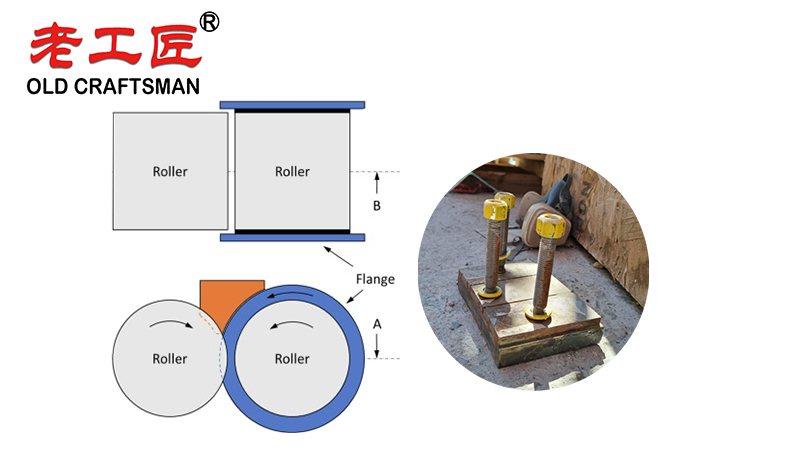

Key Applications in HPGRs

- Roll studs

- Wear plates & liners

- Feed hoppers

Our innovative Service Life Extension Program (SLEP) for high pressure pipe flange systems incorporates advanced tungsten carbide coatings and inserts on critical wear parts, delivering superior wear resistance that significantly extends the service life and enhances overall operational life. Featuring a wide variety of specialized carbide grades with high strength, excellent fracture toughness, and performance in high temperature environments, these abrasion resistant composite materials often enhanced through precipitation hardening techniques provide durable protection for cutting edges and sealing surfaces. This cost effective solution ensures extended service in demanding applications, offering a comprehensive approach to longevity and reliability.

Conclusion

Tungsten carbide’s unmatched hardness, compressive strength, and wear resistance make it the optimal choice for HPGR wear components, ensuring longer operational life, reduced maintenance, and higher cost efficiency in mineral processing.

By implementing these advanced tungsten carbide wear plate solutions, mining operations can significantly improve HPGR performance while reducing total cost of ownership through extended service life and improved operational efficiency.

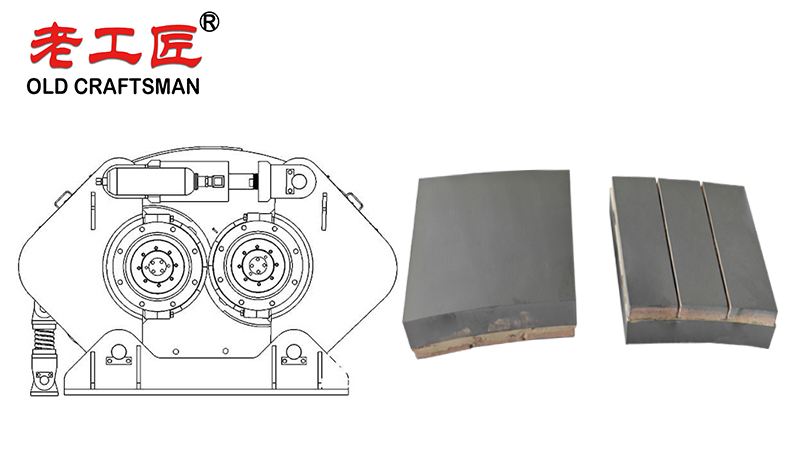

High Performance HPGR Wear Plates made from premium tungsten carbide embedded in a high strength carbon steel matrix are specifically engineered for the most demanding high temperature and corrosive environments found in mineral processing plants.

Thanks to advanced heat treatment processes and the use of highly corrosion resistant materials, these abrasion-resistant wear parts maintain exceptional mechanical properties even under continuous exposure to harsh environments and aggressive chemical reactions.

The inherently low coefficient of friction of tungsten carbide, combined with superior hardness and toughness, delivers outstanding long term performance, dramatically extending service life compared to conventional solutions.

This results in a wide range of operational benefits: significantly reduced maintenance downtime, lower overall operating costs, and a proven service life extension program that keeps HPGRs running at peak efficiency for years in the toughest conditions.

Investing in these high quality, high performance wear parts ensures maximum reliability and productivity in even the most abrasive and corrosive high-pressure grinding applications.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding