Mining operations face constant challenges from abrasive materials, heavy loads, and harsh environments, leading to frequent equipment wear and costly downtime. Tungsten carbide (WC) wear plates have emerged as a superior solution, offering exceptional durability and significantly extending the lifespan of mining equipment.

Why Tungsten Carbide Wear Plates?

Tungsten carbide is one of the hardest materials available, second only to diamond. When used in wear plates, it provides:

- Extreme Abrasion Resistance – Withstands constant friction from rocks, ores, and slurries.

- Impact Resistance – Maintains structural integrity even under heavy loads and high-impact conditions.

- Corrosion Resistance – Performs well in wet or chemically aggressive environments.

- Longer Service Life – Outlasts traditional steel plates by 5-10 times, reducing replacement frequency.

Applications in Mining

Tungsten carbide wear plates are used in critical mining equipment, including:

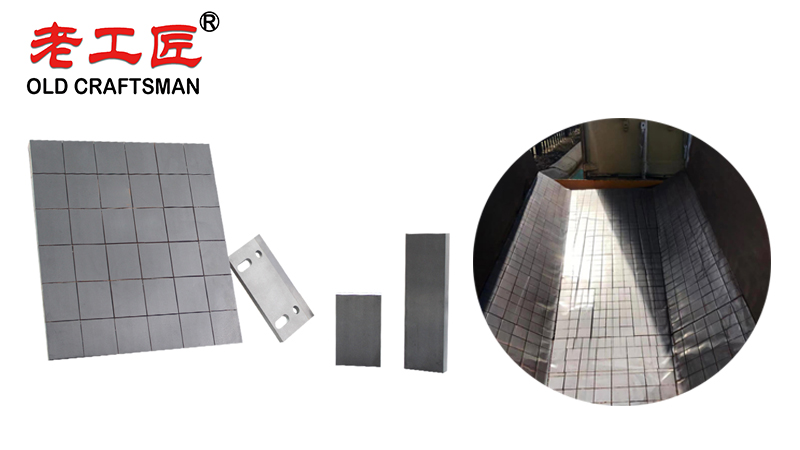

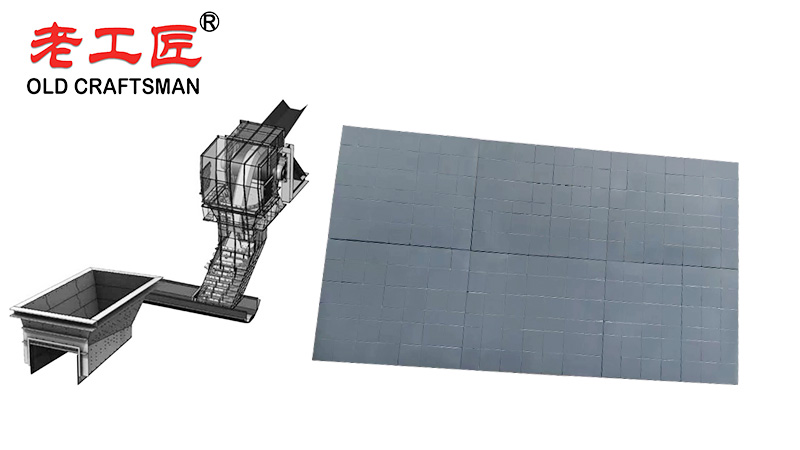

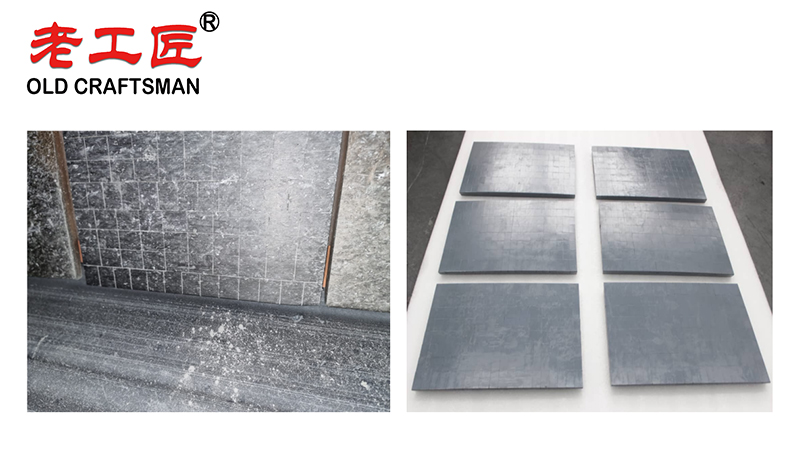

- Chutes & Hoppers – Preventing wear from high velocity material flow.

- Excavator Buckets & Loader Blades – Reducing wear from digging and loading abrasive materials.

- Screens & Crushers – Enhancing durability in crushing and screening operations.

- Pump Casings & Pipelines – Protecting against slurry erosion.

Benefits for Mining Operations

- Reduced Downtime – Fewer replacements mean less equipment stoppage.

- Lower Maintenance Costs – Longer lifespan decreases the need for frequent repairs.

- Increased Productivity – Continuous operation with minimal interruptions.

- Cost Efficiency – Despite a higher upfront cost, the long term savings are substantial.

Carbide wear plates are widely used in large scale, high quality critical minerals mining operations particularly in room and pillar mining as highly effective, wear resistant protective layers for equipment that must withstand long term exposure to extreme conditions. Made from advanced raw materials combining tungsten carbide with precious metals or cobalt binders, these plates offer exceptional mechanical properties, including superior hardness, toughness, and performance at high temperatures. Depending on the specific application (such as chute liners, grizzly bars, or excavator bucket protection during overburden removal), different types of carbide wear plates and corrosion resistant materials can be selected from a wide range to maximize durability, significantly reduce maintenance downtime, and lower overall environmental impact through extended service life and reduced replacement frequency.

Conclusion

Tungsten carbide wear plates are a game changer for the mining industry, drastically reducing downtime and maintenance costs while improving operational efficiency. By investing in these ultra durable components, mining companies can achieve greater productivity and profitability.

Need help choosing the best wear plate for your application? Consult Zhuzhou Old Craftsman Precision Alloy Co., Ltd. to optimize your mining equipment’s lifespan and efficiency.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding