Tungsten carbide scrapers significantly improve mining efficiency and reduce downtime by leveraging the material’s exceptional hardness, wear resistance, and durability. Here’s how they contribute:

1. Enhanced Wear Resistance & Longevity

- Tungsten carbide (WC) is one of the hardest materials available (9+ on the Mohs scale), making scrapers highly resistant to abrasion from rocks, ores, and slurry.

- Compared to steel scrapers, carbide-tipped versions last 5–10 times longer, reducing the frequency of replacements.

2. Reduced Downtime for Maintenance

- Fewer replacements mean less frequent stoppages for scraper changes, keeping mining operations running longer.

- Minimized unplanned maintenance delays due to sudden failures.

3. Improved Cutting & Material Handling Efficiency

- Carbide scrapers maintain sharp edges longer, ensuring consistent material removal from conveyor belts, crushers, and screens.

- Prevents material buildup (e.g., sticky ores, coal), reducing blockages and improving throughput.

4. Corrosion & Impact Resistance

- Resists chemical corrosion from acidic/alkaline mining environments.

- Handles high impact loads without chipping, crucial for heavy duty mining applications.

5. Cost Savings Over Time

- Despite higher upfront costs, the extended lifespan reduces total cost of ownership (TCO) by lowering replacement and labor costs.

Key Applications in Mining:

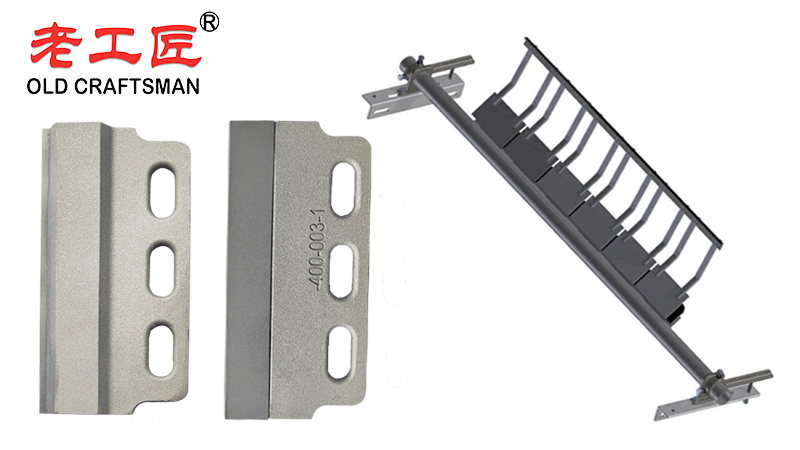

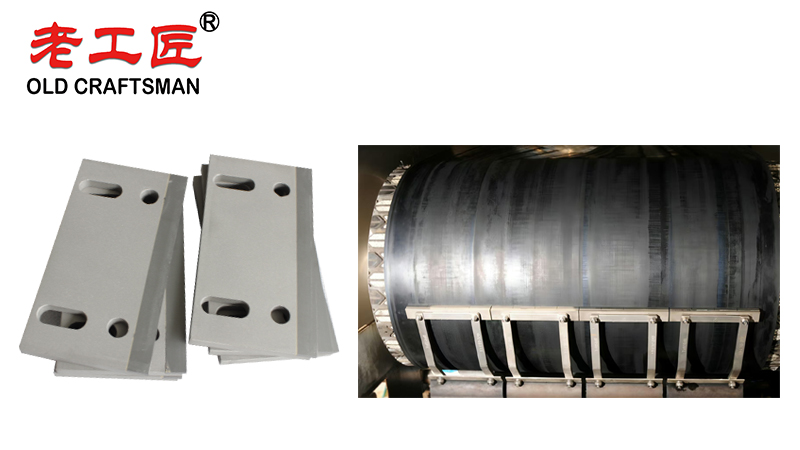

- Conveyor Belt Cleaning – Prevents carryback, reducing belt wear and spillage.

- Crusher & Mill Liners – Protects equipment from abrasive wear.

- Screening Systems – Maintains efficient ore separation with minimal clogging.

A high-quality mining conveyor belt scraper is an essential part of modern material handling systems in open pit and underground operations. By effectively removing residual bulk materials, raw materials, and even sticky finished products from the belt surface, the scraper keeps belts clean across a wide range of transported materials. This simple yet critical cleaning system significantly improves efficiency in the entire material handling process, ensures better control of materials, minimizes downtime caused by carryback buildup, and reduces the environmental impact through less spillage and dust generation. As mining operations become increasingly automated, reliable conveyor belt scrapers play a key role in maintaining smooth, continuous movement of materials while lowering maintenance costs and extending belt life.

Conclusion:

By minimizing wear related failures and maintenance intervals, tungsten carbide scrapers optimize operational uptime, lower costs, and boost productivity in harsh mining environments. Investing in high quality carbide scrapers ensures long term efficiency gains.

Need help choosing the right tungsten carbide scraper for your conveyor? Consult Zhuzhou Old Craftsman Precision Alloy Co., Ltd. to optimize your mining equipment’s lifespan and efficiency.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding