The replacement frequency for conveyor belt carbide scrapers in mining operations depends on several factors, including:

Key Factors Affecting Replacement Frequency

- Material Abrasiveness – Highly abrasive ores (e.g., iron ore, granite, quartz) wear out scrapers faster than softer materials (e.g., coal, limestone).

- Belt Speed & Load – Faster belt speeds and heavier loads increase wear.

- Scraper Alignment & Pressure – Misaligned or overly tight scrapers wear unevenly and require more frequent replacement.

- Environmental Conditions – Wet, muddy, or corrosive environments accelerate wear.

- Carbide Quality – Premium tungsten carbide scrapers last longer than lower grade alternatives.

General Replacement Guidelines

| Application | Expected Lifespan |

|---|---|

| Highly abrasive ores (iron, copper, gold) | 3–6 months |

| Moderately abrasive materials (coal, limestone) | 6–12 months |

| Non-abrasive materials (sand, gravel) | 12–24 months |

Signs It’s Time to Replace Carbide Scrapers

✔ Visible wear (carbide tips worn down by 50% or more)

✔ Reduced cleaning efficiency (material buildup on the belt)

✔ Uneven wear patterns (indicating misalignment)

✔ Increased belt wear (due to poor scraping contact)

Best Practices to Extend Scraper Life

- Regular inspections (monthly checks for wear and alignment)

- Proper tensioning (avoid excessive pressure on the belt)

- Use high-quality tungsten carbide (longer-lasting than steel or ceramic alternatives)

- Rotate or flip scrapers (if double-edged) to maximize lifespan

Conclusion

In mining operations, carbide scrapers typically last 3–12 months, but harsh conditions may require more frequent replacement. Regular monitoring and maintenance are key to optimizing performance and avoiding belt damage.

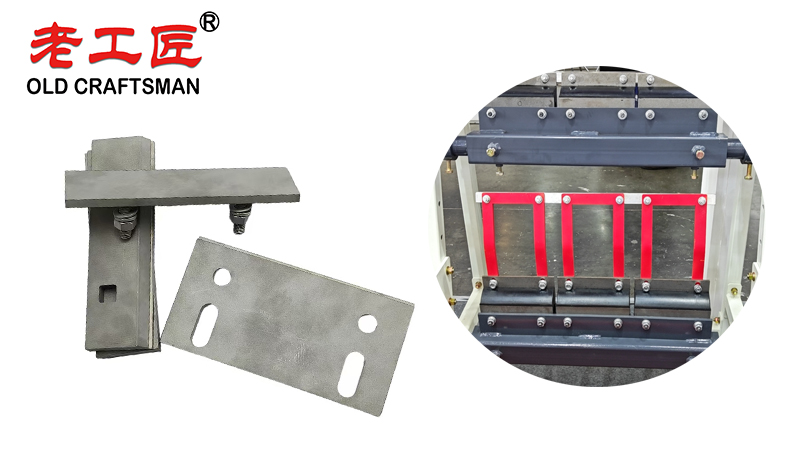

Tungsten carbide scrapers are the optimal choice for mining conveyor systems due to their unmatched wear resistance, efficiency in material removal, and long term cost savings. They help maintain belt longevity, reduce maintenance, and improve operational efficiency in abrasive mining environments.

In demanding industrial applications such as mining and cement production, conveyor belt scrapers operating under high temperatures require high performance, wear resistant materials to ensure long term reliability and cost efficiency. Traditional stainless steel or standard wear parts simply cannot withstand the extreme abrasion caused when the scraper continuously removes material from the belt. This is why high quality, cost effective solutions increasingly rely on advanced cemented carbide and silicon carbide components. These engineered materials, often reinforced with tungsten carbide rings or featuring a cutting edge made of premium grade carbide inserts and cutting tools, deliver exceptional durability across a wide range of raw materials from naturally occurring ores to processed aggregates. By upgrading to carbide based scrapers and wear parts, operators significantly extend service life, reduce downtime, and achieve superior performance even in the harshest, high temperature environments.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding