Tungsten carbide (WC) is an exceptional material choice for intensive mixer blades due to its outstanding properties, making it ideal for demanding mixing applications in industries like ceramics, powder metallurgy, chemicals, and pharmaceuticals. Below are the key benefits of using tungsten carbide for intensive mixer blades:

1. Exceptional Wear Resistance

- Tungsten carbide is one of the hardest materials available (HV ~1600-2000), significantly outperforming steel and even some ceramics.

- Resists abrasive wear from hard particles (e.g., ceramics, metal powders), extending blade lifespan.

- Reduces downtime and maintenance costs compared to traditional steel blades.

2. High Strength & Toughness

- Combines extreme hardness with good fracture toughness (especially in WC-Co grades).

- Withstands high mechanical stresses and impacts without chipping or cracking.

- Ideal for mixing dense or viscous materials that exert heavy loads on the blades.

3. Corrosion & Chemical Resistance

- Highly resistant to acids, alkalis, and corrosive environments (especially when using nickel-bonded WC grades).

- Suitable for mixing chemically aggressive materials (e.g., battery slurries, pharmaceuticals).

4. Heat Resistance & Stability

- Maintains hardness and structural integrity at high temperatures (up to ~500–600°C).

- Resists thermal fatigue, making it suitable for mixing processes involving heat generation.

5. Improved Mixing Efficiency & Consistency

- Sharp edges retain their profile longer, ensuring uniform mixing over extended periods.

- Reduces material buildup (anti-adhesion properties), preventing contamination.

6. Cost-Effectiveness Over Long Term

- Despite higher initial costs, WC blades last significantly longer than steel alternatives.

- Lower replacement frequency reduces operational disruptions and long-term costs.

Applications of Tungsten Carbide Mixer Blades

- Ceramics & Powder Metallurgy: Mixing hard abrasive powders like alumina, zirconia, or tungsten.

- Battery Manufacturing: Homogenizing electrode slurries (Li-ion battery production).

- Pharmaceuticals: Precise mixing of active ingredients without contamination.

- Chemical Processing: Handling corrosive or high wear mixtures.

Considerations When Using Tungsten Carbide Blades

- Optimal Grade Selection: Cobalt-bonded WC offers toughness, while nickel-bonded grades enhance corrosion resistance.

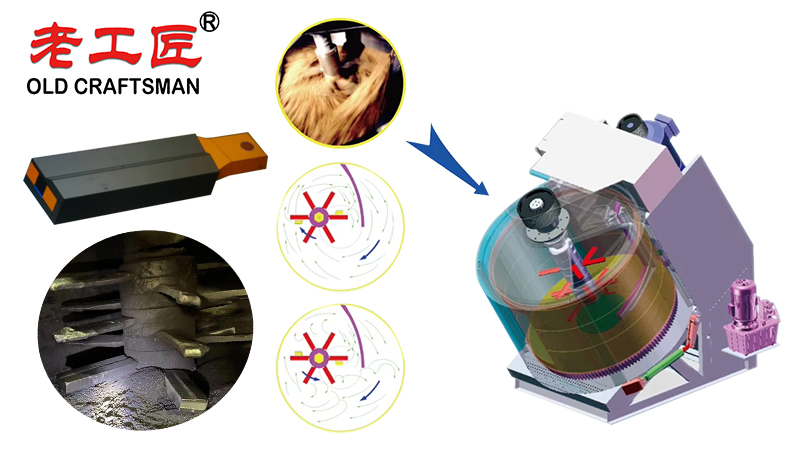

- Design & Geometry: Precision engineering ensures optimal performance and stress distribution.

- Cost-Benefit Analysis: Justified for high wear applications but may be overkill for less demanding mixes.

Conclusion

Tungsten carbide mixer blades provide unmatched durability, efficiency, and longevity in harsh mixing environments. While the upfront cost is higher, the reduction in maintenance, downtime, and replacement frequency makes them a superior choice for intensive mixing applications.

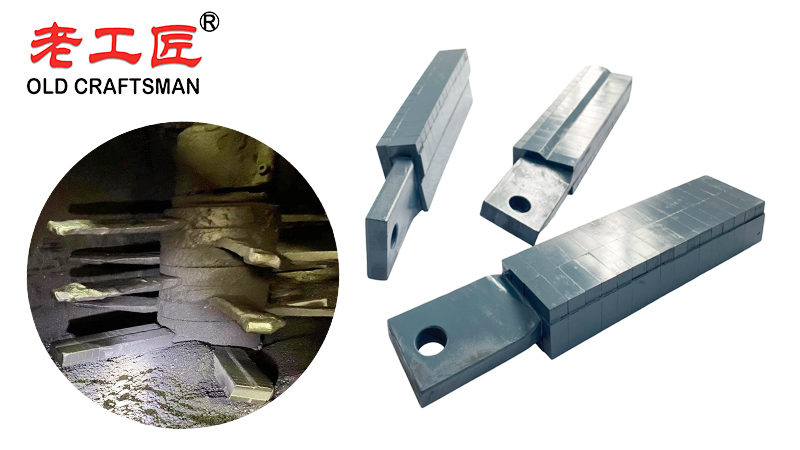

In the design of carbide intensive mixers, the blades operate under extremely high temperatures and severe abrasive conditions, requiring wear parts made from cemented carbide (typically tungsten carbide) rather than conventional stainless steel or mild steel. These wear resistant materials offer exceptional high strength, superior mechanical properties, and a very high melting point (around 2,870 °C for pure tungsten), making them ideal for applications involving high strain rate deformation and intense mechanical stress. Unlike elastic materials that deform reversibly, cemented carbide maintains rigidity and a razor-sharp cutting edge even after prolonged exposure to aggressive compounds. This combination of outstanding material properties ensures a wide range of high performance applications, from cutting tools and tungsten carbide rings to heavily loaded resist material components found in mining, recycling, and concrete processing equipment. For the best durability in such environments, simply toggle the table of contents of any materials selection handbook and you will find cemented carbide consistently recommended over stainless or mild steel alternatives.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding