Enhancing mining transfer chutes with tungsten carbide (WC) wear linings significantly improves durability, reduces maintenance costs, and increases operational efficiency. Here’s a detailed breakdown of the benefits and considerations:

Key Benefits of Tungsten Carbide Wear Linings in Mining Transfer Chutes

- Exceptional Wear Resistance

- Tungsten carbide is one of the hardest materials available (HV 1500-2000), offering superior resistance to abrasion from ore, coal, and other abrasive materials.

- Outlasts traditional materials like AR steel, ceramic liners, and UHMW polyethylene by 3-10 times.

- Impact Resistance

- WC linings can withstand high impact loads from large rocks and heavy material flow, reducing cracking and spalling risks compared to brittle alternatives.

- Reduced Downtime & Maintenance

- Longer service life means fewer replacements, minimizing production interruptions.

- Ideal for high wear zones like transfer points, loading zones, and cascading chutes.

- Improved Material Flow

- Smooth or engineered surface designs (e.g., studded or tile layouts) reduce material buildup and blockages.

- Low friction coefficient prevents sticky material adhesion.

- Corrosion & Heat Resistance

- Performs well in wet, acidic, or high temperature environments, unlike steel, which can corrode or degrade.

Common Tungsten Carbide Lining Solutions

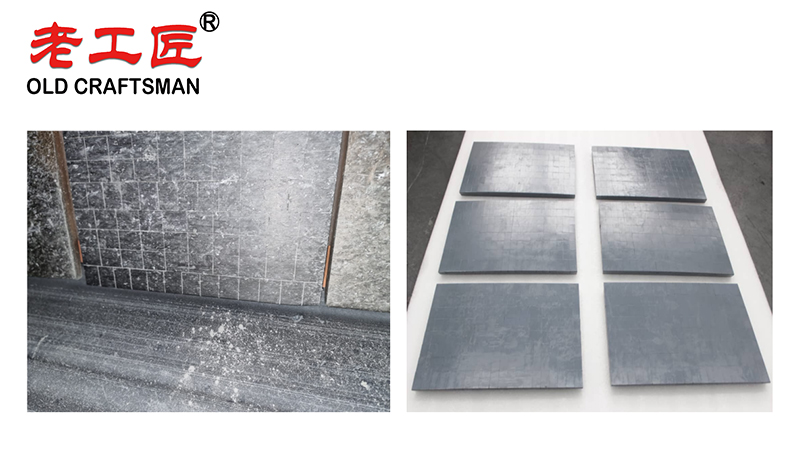

- Carbide Tiles/Plates – Bolted or welded onto chute surfaces for localized high wear protection.

- Carbide Stud Liners – Embedded tungsten carbide studs in a steel matrix for impact + abrasion resistance.

- Overlay Cladding – WC coatings applied via thermal spray or weld overlay for seamless protection.

Applications in Mining

- Ore Transfer Chutes (iron, copper, gold)

- Coal Handling Plants

- Slurry & Tailings Systems

- Crusher Feed & Discharge Points

Considerations for Implementation

✔ Initial Cost vs. Lifetime ROI – Higher upfront cost but lower total cost of ownership due to extended lifespan.

✔ Installation Expertise – Requires proper welding/bolting techniques to avoid premature failure.

✔ Custom Design – Liners should be tailored to chute geometry and material flow patterns.

Tungsten carbide wear liners play an important role in heavy duty industrial applications where extreme abrasive wear, high temperature, and severe impact conditions are present. Widely used in bulk material handling equipment such as conveyor systems, chutes, hoppers, and truck bed linings, these liners deliver outstanding abrasion resistance and dramatically extended service life compared to conventional high carbon or abrasion resistant steels and other wear resistant materials.

Thanks to their exceptional hardness (typically 86–93 HRA), high strength, and superior mechanical properties, tungsten carbide wear plates provide long-term protection in the most demanding environments, significantly reducing downtime and maintenance costs. Multiple test methods (ASTM G65 dry sand abrasion test, ASTM B611, etc.) consistently demonstrate that tungsten carbide liners can achieve 10–30 times greater wear resistance than AR400/AR500 high wear abrasion resistant steels, making them one of the most cost effective solutions over the long term despite higher initial investment.

Available in a wide range of thicknesses, sizes, and configurations, tungsten carbide wear liners offer proven performance and exceptional cost effectiveness in mining, cement, power generation, recycling, and other high wear industries.

Conclusion

Tungsten carbide wear linings are a high performance solution for mining transfer chutes, drastically reducing wear related failures and improving productivity. For maximum effectiveness, partner with a supplier specializing in custom carbide solutions for mining applications.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear plates, Liners for HPGR Feed Chute and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding