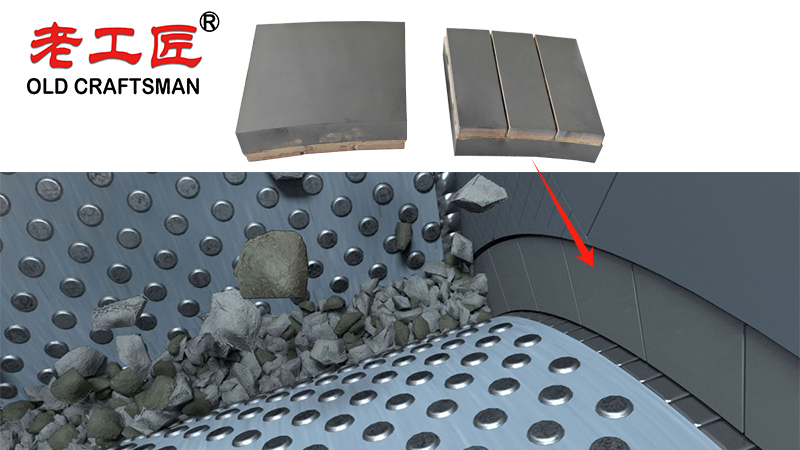

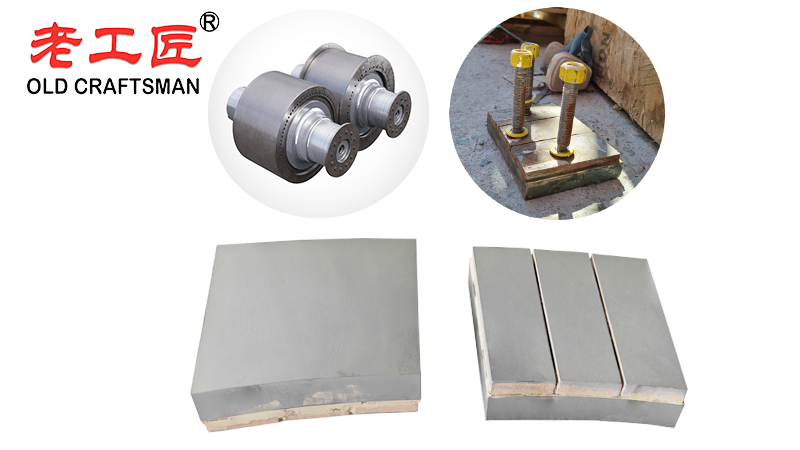

Tungsten carbide (WC) is widely recognized for its exceptional durability in high pressure grinding roll (HPGR) flanges in mining applications. Here’s a breakdown of its key advantages:

1. Extreme Hardness & Wear Resistance

- Tungsten carbide has a Vickers hardness of 1,500–2,200 HV, far exceeding hardened steel (~800 HV).

- This makes it highly resistant to abrasion, erosion, and gouging from hard ore particles, significantly extending flange lifespan.

2. High Compressive Strength

- WC can withstand over 6,000 MPa of compressive stress, making it ideal for HPGRs, where flanges endure extreme pressures (up to 250 MPa).

- Unlike steel, it resists deformation under load, maintaining dimensional stability.

3. Corrosion & Impact Resistance

- Resists chemical wear from slurry and acidic/alkaline conditions in ore processing.

- Engineered WC grades with cobalt/nickel binders improve toughness, reducing crack propagation.

4. Cost Efficiency Over Time

- While initial costs are higher than steel, WC flanges last 3–5 times longer, reducing downtime and replacement frequency.

- Lower maintenance costs and increased throughput justify the investment.

5. Thermal Stability

- Maintains performance even at elevated temperatures generated during grinding.

Comparison with Steel Flanges

| Property | Tungsten Carbide | Hardened Steel |

|---|---|---|

| Hardness (HV) | 1,500–2,200 | ~800 |

| Compressive Strength | 6,000+ MPa | 2,500 MPa |

| Wear Life | 3–5x Longer | Baseline |

Conclusion

Tungsten carbide’s superior hardness, strength, and wear resistance make it the optimal choice for HPGR flanges in mining, ensuring longer service life, reduced downtime, and lower total cost of ownership compared to traditional steel alternatives.

For HPGR flanges, tungsten carbide is unmatched in durability, wear resistance, and operational efficiency, making it the preferred choice in modern mining operations. Its ability to withstand extreme pressure and abrasion ensures longer lifespan and lower total cost of ownership compared to steel or ceramic alternatives.

With decades of years of experience in advanced materials engineering, our HPGR carbide flanges are specifically designed for the most demanding wear applications. Manufactured from premium cemented carbide and tool steel-based raw materials with an extremely high melting point, these components deliver exceptional mechanical properties even at high temperatures across a wide range of operating conditions. The outstanding combination of high wear resistance, superior abrasion resistant performance, and excellent corrosion resistant characteristics makes them the preferred choice for wear parts, cutting tools, and critical components in industrial equipment. Thanks to their high resistance to both abrasive and corrosive environments, together with a remarkably low coefficient of friction, our high-performance carbide solutions significantly extend service life in stainless steel processing and other severe duty applications, providing unmatched durability and reliability for high wear environments worldwide.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding