High-Pressure Grinding Rolls (HPGR) are widely used in mining and cement industries to crush and grind ores and materials efficiently. Tungsten carbide edge blocks and studs are critical components in HPGR systems, enhancing durability and performance due to their exceptional hardness and wear resistance. Here’s an overview based on available information:

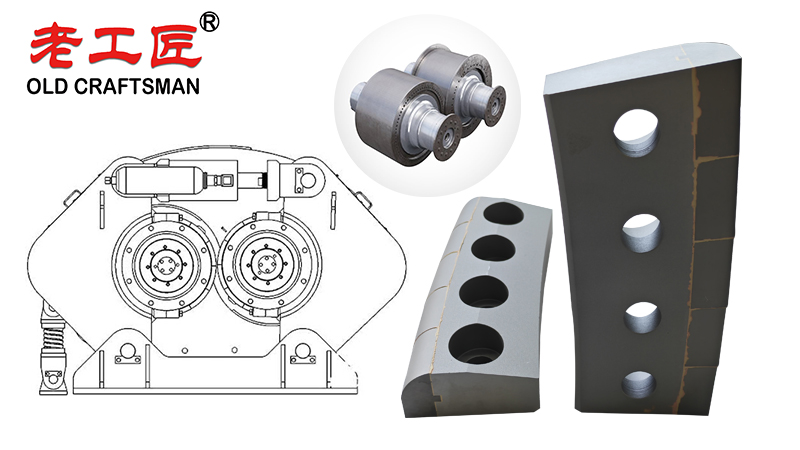

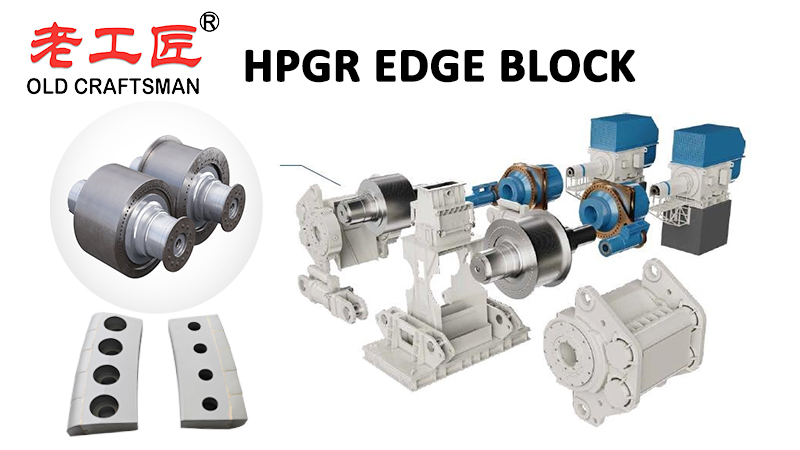

Key Features of Tungsten Carbide Edge Blocks for HPGR

- Material Properties: Tungsten carbide, often combined with cobalt or tantalum, offers extreme hardness (up to HRA 88.6 or HRC 67+), high compressive strength (up to 3000 MPa), and superior wear resistance, making it ideal for the abrasive conditions of HPGR operations.

- Function: Edge blocks protect the roller edges, while studs embedded on the roller surface handle direct crushing. Together, they ensure efficient comminution, reducing particle size and improving mineral liberation.

- Durability: Tungsten carbide edge blocks and studs extend roller life by 5–10 times compared to traditional surfacing or centrifugal casting methods, reducing maintenance frequency and downtime.

- Customization: Available in various shapes (e.g., flat top, ball head, pin head) and sizes with dimensional tolerances up to ±0.001mm, tailored to specific HPGR models and feed materials like iron ore, gold, copper, or cement clinker.

Benefits in Mining Applications

- Enhanced Grinding Efficiency: The high hardness and grip of tungsten carbide improve material crushing, leading to finer particle sizes and better mineral recovery.

- Energy Savings: HPGR with tungsten carbide components reduces energy consumption compared to traditional grinding methods, contributing to cost effectiveness.

- Reduced Maintenance Costs: The wear resistant properties minimize the need for frequent replacements, lowering operational costs.

- Sustainability: Using durable tungsten carbide components supports longer equipment life and aligns with recycling efforts, reducing environmental impact. Recycling tungsten carbide requires significantly less material than primary mining (70 kg of carbide yields the same tungsten as 15 tons of mined ore).

Applications

- Hard rock mining: Gold, copper, iron ore, platinum

- Diamond processing: Kimberlite crushing

- Abrasive aggregates: Quartzite, granite processing

- Industrial minerals: High silica applications

Specific Solutions and Manufacturers

- Zhuzhou Old Craftsman Precision Alloy Co.,Ltd.: Provides edge blocks and flanges with over 10,000 hours of service life, suitable for grinding iron ore, limestone, and cement clinker. Their products are customizable and backed by ISO 9001 and ISO 14001 certifications.

Maintenance and Optimization

- Proper Installation: Precise sizing and installation ensure even stress distribution, maximizing stud and edge block lifespan. Lubrication and surface coatings further enhance wear resistance.

- Regular Maintenance: Inspections, cleaning, and timely replacement of worn components are essential to maintain HPGR performance and prevent excessive wear.

- Future Developments: Advances in sensor technology and automation are being integrated into HPGR systems for real-time wear monitoring and process optimization.

Environmental and Economic Impact

- Sustainability: Tungsten carbide’s durability reduces the need for frequent replacements, and recycling programs (e.g., Hyperion’s) support a circular economy, minimizing environmental impact compared to primary tungsten mining.

- Cost-Effectiveness: The long lifespan and reduced maintenance needs of tungsten carbide components lower operational costs, while improved grinding efficiency boosts productivity.

For specific inquiries about tungsten carbide edge blocks or studs, including minimum order quantities, pricing, or delivery, contact manufacturers like TUNGSTEN MAN ([email protected]) or visit their websites for quotes.. Alternatively, check with Hyperion Materials & Technologies for recycling options and tailored solutions.

HPGR Edge Blocks made from high temperature resistant tungsten carbide (WC) are critical wear parts in high pressure grinding rolls (HPGR), offering superior abrasive resistant and corrosion resistant performance compared to traditional grinding media used in ball mills. These edge blocks, manufactured from carefully selected carbide powders with optimized grain size and exceptional compressive strength, protect the roll surface under extreme operating parameters and high speed grinding conditions. By maintaining stable physical properties even during intense fine grinding of hard raw materials, WC edge blocks significantly extend equipment life, improve energy efficiency, and enable optimizing grinding performance across a wide range of minerals and ores in modern high pressure comminution processes.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding