Conveyor belt cleaning systems play a critical role in mining operations by maintaining belt cleanliness, reducing material carryback, and preventing equipment damage. Advanced carbide scrapers offer significant advantages over traditional cleaning solutions in harsh mining environments.

Key Benefits of Advanced Carbide Scrapers

1. Superior Wear Resistance

- Tungsten carbide blades withstand abrasive mining materials (ore, coal, aggregates)

- 5-10x longer service life compared to polyurethane or steel scrapers

- Maintains consistent cleaning performance throughout wear cycle

2. Enhanced Cleaning Efficiency

- Removes up to 99% of carryback material when properly installed

- Reduces belt wear from trapped abrasive particles

- Minimizes material loss (saving 0.5-2% of transported material)

3. Operational Cost Reduction

- Lower replacement frequency reduces maintenance downtime

- Decreased spillage cleanup costs

- Reduced belt replacement costs (up to 30% longer belt life)

Implementation Best Practices

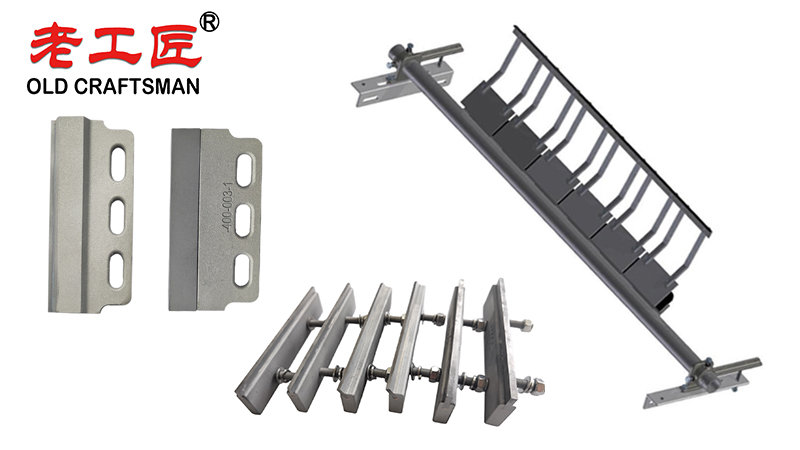

Optimal Installation

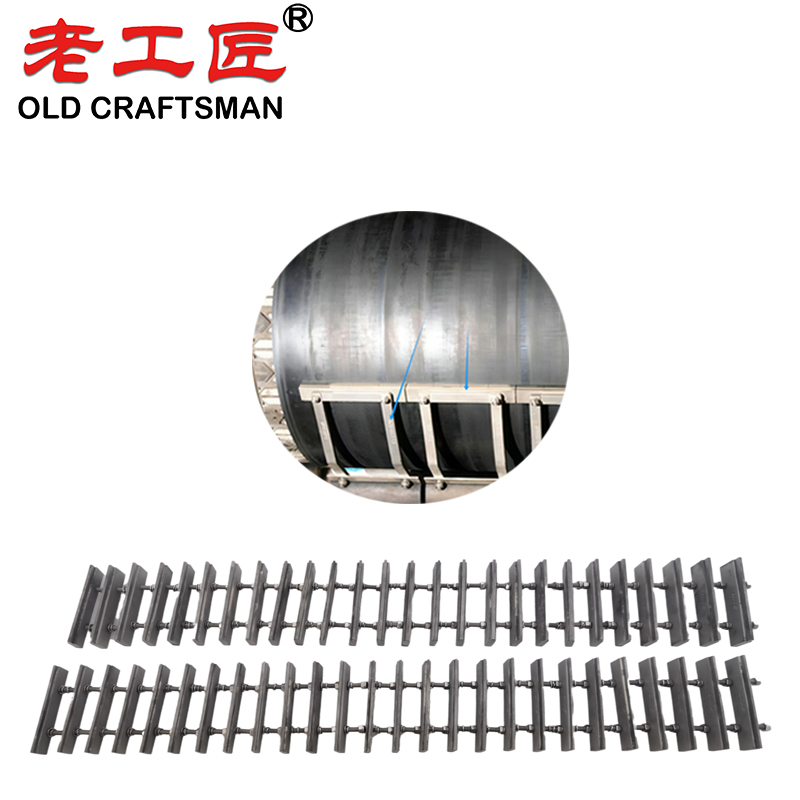

- Primary scraper: Positioned at discharge point at 30-45° angle to belt

- Secondary scraper: Installed for final cleaning

- Proper tensioning to ensure consistent contact without excessive wear

Maintenance Considerations

- Regular inspection (recommended monthly in mining applications)

- Blade rotation to utilize full wear surface

- Quick change systems to minimize downtime

Productivity Impact

- Reduced unplanned downtime by 15-25% in case studies

- Increased system uptime through reliable cleaning

- Improved workplace safety by reducing slip hazards from spillage

Selection Criteria

When choosing carbide scrapers for mining applications consider:

- Material abrasiveness

- Belt speed and width

- Moisture content of transported material

- Operating temperature range

Advanced carbide scrapers represent a cost effective upgrade that can significantly improve the efficiency and productivity of mining conveyor systems while reducing operational costs.

In large-scale processing plants for raw materials and building materials, high temperature conveyor belts are essential components that face extreme abrasive wear and harsh conditions. To ensure optimal performance and longevity, manufacturers use advanced wear resistant materials with a low coefficient of friction for both the belts and the critical belt cleaners (scrapers). These high performing, heat resistant belt cleaners effectively remove sticky residues and minimize carryback, reducing environmental impact, improving workplace safety, and meeting strict Occupational Safety and Health Administration (OSHA) standards while lowering maintenance costs and downtime in demanding industrial environments.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding