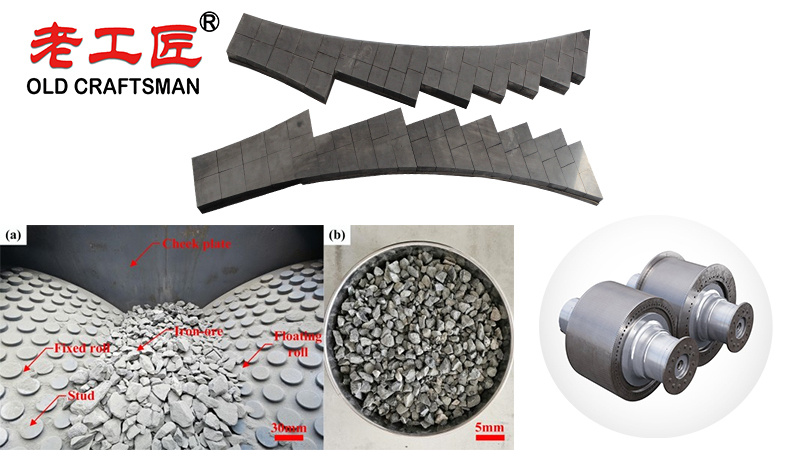

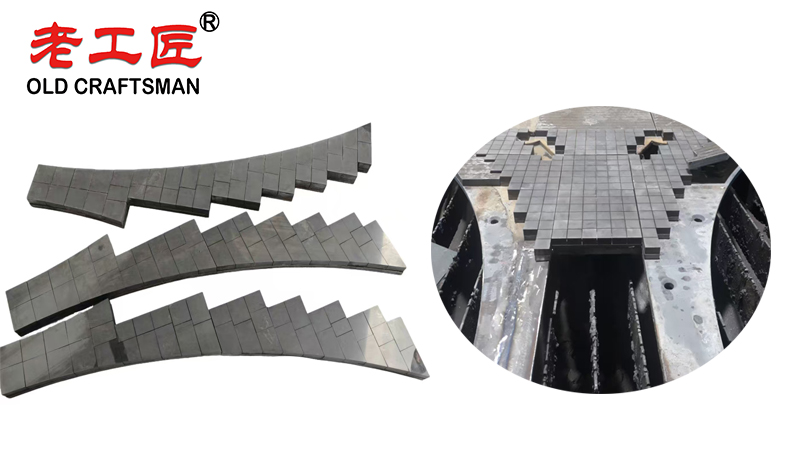

HPGR (High Pressure Grinding Roll) carbide cheek plates significantly improve grinding efficiency by optimizing material flow, reducing wear, and maintaining consistent pressure. Their tungsten carbide construction provides superior durability and performance compared to traditional steel plates. Here’s how they contribute to energy efficient grinding:

1. Superior Wear Resistance for Consistent Grinding Performance

- Tungsten carbide is extremely hard (HV 1400-1800) and abrasion resistant, far outperforming steel cheek plates.

- Reduces wear-related inefficiencies maintaining a tight gap between rolls and cheek plates for longer periods, ensuring optimal material confinement.

- Minimizes downtime for plate replacements, keeping the HPGR operating at peak efficiency.

Impact on Energy Efficiency:

✔ Less frequent maintenance = sustained grinding efficiency

✔ No gradual performance drop-off = consistent energy use per ton

2. Enhanced Material Containment & Reduced Side Leakage

- Carbide cheek plates provide a precise seal against the rolls, preventing feed material from escaping sideways.

- Ensures maximum material enters the compression zone, improving interparticle crushing efficiency.

Impact on Energy Efficiency:

✔ Less recirculation = lower energy waste reprocessing escaped material

✔ Higher throughput with the same energy input

3. Optimized Pressure Distribution for Efficient Particle Breakage

- The rigidity of carbide maintains uniform pressure distribution across the grinding zone.

- Prevents edge effects (pressure drop at roll ends), ensuring consistent breakage forces.

- Promotes interparticle crushing (more energy efficient than direct roll-to-particle breakage).

Impact on Energy Efficiency:

✔ Lower specific energy consumption (kWh/t) due to efficient particle fracture mechanics

✔ More uniform product size = less need for downstream grinding

4. Reduced Friction & Heat Generation

- Carbide’s smooth surface and low coefficient of friction reduce heat buildup compared to steel.

- Less energy lost to frictional heat means more power is used for grinding.

Impact on Energy Efficiency:

✔ Lower operating temperatures = reduced energy waste

✔ Extended roll and cheek plate life = lower long term energy costs

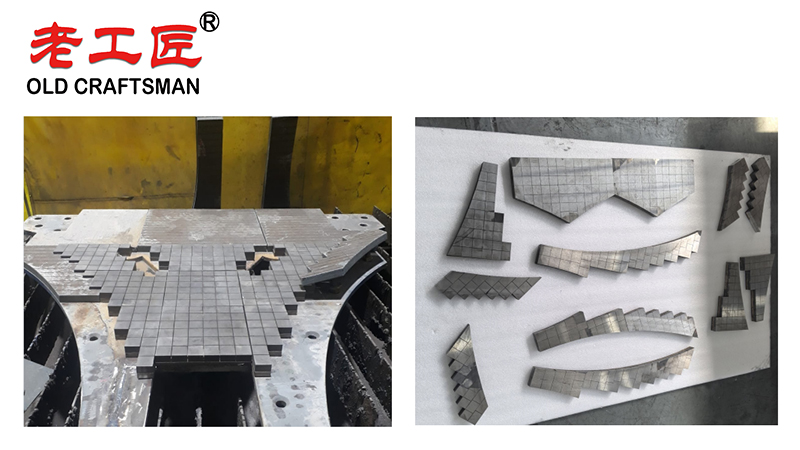

5. Longer Lifespan = Lower Operational Costs & Energy Waste

- Carbide cheek plates last 3-5x longer than steel versions.

- Fewer replacements mean:

- Less downtime (maintaining steady energy efficient operation)

- Lower replacement energy costs (manufacturing, transport, installation)

Impact on Energy Efficiency:

✔ Reduced lifecycle energy consumption per ton of ore processed

Case Study: Energy Savings with Carbide Cheek Plates

A copper mine replacing steel cheek plates with carbide versions reported:

- 15-20% reduction in specific energy consumption (kWh/t)

- 30% longer service life, reducing maintenance shutdowns

- 5-10% higher throughput due to better material confinement

Conclusion: Why Carbide Cheek Plates Improve HPGR Energy Efficiency

- Minimized wear → Consistent grinding pressure

- Reduced side leakage → More efficient interparticle crushing

- Lower friction & heat loss → More energy directed into grinding

- Longer lifespan → Fewer replacements, less downtime

By upgrading to carbide cheek plates, HPGRs achieve higher energy efficiency, lower operating costs, and more sustainable grinding compared to traditional steel alternatives.

The industrial sector can significantly reduce greenhouse gas emissions and total energy consumption in the long term by adopting cost effective technologies such as HPGR cheek plates and heat pumps in power plants. High Pressure Grinding Rolls (HPGR) equipped with durable cheek plates offer substantial improvements in energy efficiency, lowering the amount of energy required for mineral processing while reducing wear and maintenance costs ultimately saving money for operators. Meanwhile, integrating heat pumps and renewable energy sources into electricity generation allows power plants to deliver improved energy services with far less energy consumed compared to traditional fossil fuel systems. These combined advances not only cut energy bills for industry but also contribute to cleaner electric power production and a meaningful reduction in overall greenhouse gas output.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could production tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized tungsten carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding