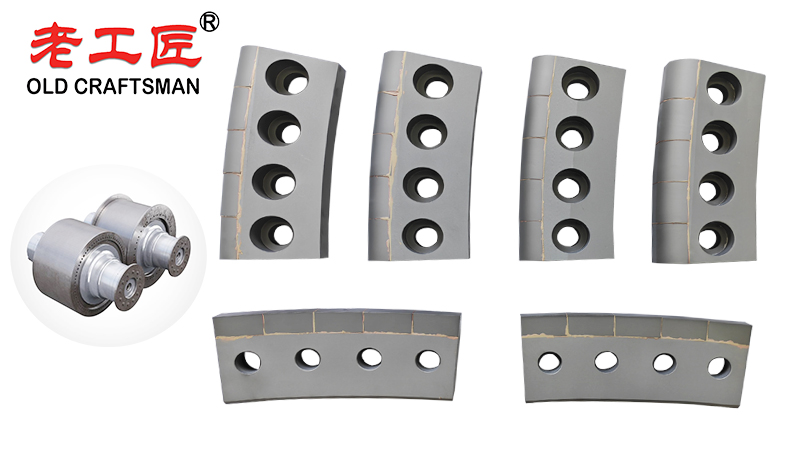

Tungsten carbide edge blocks are critical components in High Pressure Grinding Rolls (HPGR) used in mining operations, offering significant advantages due to their unique material properties. Below are the key benefits, based on their application in HPGR systems:

- Enhanced Equipment Longevity: By mitigating the “edge effect” where uneven pressure distribution at the roll edges causes excessive wear tungsten carbide edge blocks protect the roll surfaces, significantly extending the operational life of HPGR equipment. This durability translates to lower maintenance costs and improved reliability.

- Superior Wear Resistance: Tungsten carbide (WC) edge blocks are exceptionally hard and durable, capable of withstanding the intense abrasion and high pressure conditions encountered in grinding tough materials like iron ore, cement clinker, limestone, and bauxite. This leads to extended service life compared to traditional materials, reducing the frequency of replacements and downtime.

- Energy Efficiency: HPGR systems equipped with tungsten carbide edge blocks reduce specific energy consumption compared to conventional crushing or ball milling methods. This is due to their ability to maintain optimal grinding performance, which minimizes energy waste and lowers operational costs.

- Improved Grinding Efficiency: The consistent grinding gaps maintained by tungsten carbide edge blocks ensure uniform pressure distribution, resulting in higher throughput and more efficient crushing. This leads to better particle size distribution, which enhances downstream processes like flotation and leaching, ultimately improving overall productivity.

- Cost-Effectiveness: Although tungsten carbide edge blocks may have a higher initial cost, their extended lifespan, reduced maintenance needs, and improved energy efficiency lead to a lower total cost of ownership. The ability to handle high impact and abrasive environments without frequent replacements makes them a cost effective choice for mining operations.

- Versatility Across Applications: These edge blocks are highly adaptable, suitable for grinding a variety of materials, including iron ore, cement clinker, and other minerals. Their robustness ensures consistent performance across different feed hardness levels, making them ideal for diverse mining and cement production scenarios.

- Optimized Design for Performance: Customizable sizes and precise dimensional tolerances (up to ±0.001mm) allow for high precision installation, ensuring even stress distribution across the roller surface. This reduces wear on individual components and enhances the overall performance of the HPGR system.

In summary, tungsten carbide edge blocks revolutionize HPGR operations in mining by offering unmatched wear resistance, improved efficiency, and significant cost savings. Their ability to withstand extreme conditions and maintain consistent performance makes them a critical advancement in mineral processing technology.

The innovative HPGR Edge Blocks, manufactured from high strength stainless steel, are specifically designed to resist material wear under extreme high pressures and high temperatures during the grinding process. Compared to traditional ball mill systems, this advanced technology delivers superior energy efficiency and significant energy saving, while dramatically increasing productivity and overall cost effectiveness. The precisely engineered edge blocks maintain consistent particle size distribution and maximize surface area exposure, ensuring a wide range of ore types can be processed with optimum results. Real time monitoring and long term durability further improve energy utilization, making HPGR systems a high quality, efficiency inclusive solution that reduces operational costs and enhances performance across the entire comminution circuit.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding