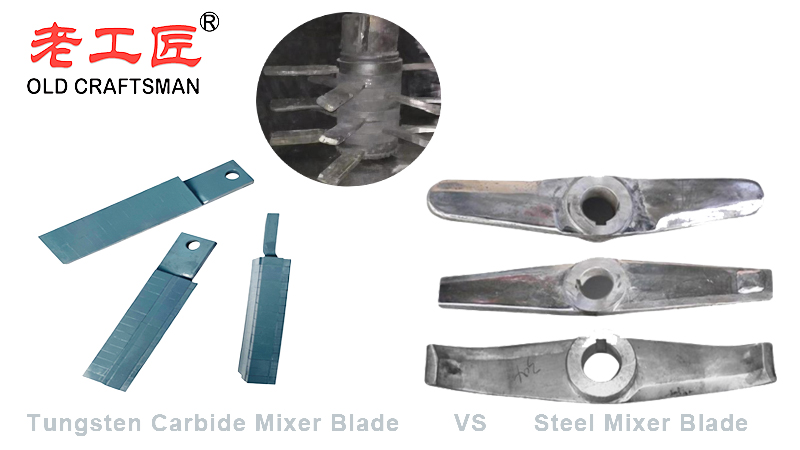

When comparing tungsten carbide (WC) and steel blades for intensive mixers, the best choice depends on the specific application, material being processed, and operational demands. Below is a detailed comparison:

1. Wear Resistance & Durability

- Tungsten Carbide (WC):

- Extremely hard (HV ~1500-2500), making it highly resistant to abrasion.

- Superior lifespan in abrasive environments (e.g., mixing ceramics, minerals, or hard powders).

- Minimal material loss over time, reducing replacement frequency.

- Steel (Tool Steel/Stainless Steel):

- Lower hardness (HV ~500-900), prone to faster wear in abrasive conditions.

- Requires frequent sharpening/replacement in high wear applications.

- Better for less abrasive materials (e.g., food, plastics, soft powders).

Winner: Tungsten Carbide for abrasive materials.

2. Impact & Fracture Toughness

- Tungsten Carbide:

- Brittle can chip or crack under high impact loads or sudden shocks.

- Unsuitable for mixing large, hard chunks that may cause impact damage.

- Steel:

- Higher toughness better at absorbing impacts without cracking.

- Preferred for mixing dense or irregular materials (e.g., metal powders, recycling scraps).

Winner: Steel for high impact applications.

3. Corrosion Resistance

- Tungsten Carbide:

- Good chemical resistance but may corrode in highly acidic/alkaline environments.

- Cobalt binder in WC can degrade in corrosive media.

- Stainless Steel (e.g., 316L):

- Excellent corrosion resistance in wet or chemically aggressive environments.

- Preferred for food, pharmaceuticals, and chemicals.

Winner: Stainless Steel for corrosive environments.

4. Cost & Maintenance

- Tungsten Carbide:

- Higher initial cost but longer lifespan in abrasive conditions.

- Justifiable for high wear industrial applications.

- Steel:

- Lower upfront cost but higher long term replacement costs.

- Easier to machine/repair.

Winner: Tungsten Carbide for long term ROI in abrasive mixing.

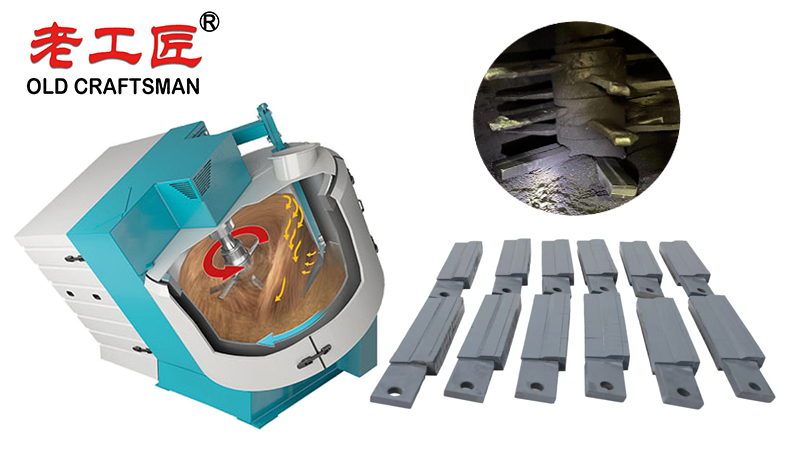

5. Performance in Intensive Mixers

- Tungsten Carbide excels in:

- High speed mixing of abrasive powders (e.g., ceramics, cement, tungsten/carbide blends).

- Applications where blade sharpness retention is critical.

- Steel is better for:

- Impact heavy mixing (e.g., metal powders, rubber compounding).

- Corrosive or food grade applications.

Final Verdict:

| Factor | Tungsten Carbide | Steel |

|---|---|---|

| Wear Resistance | ✅ Best | ❌ Poor |

| Impact Toughness | ❌ Brittle | ✅ Tough |

| Corrosion Resistance | ⚠️ Moderate | ✅ Best (Stainless) |

| Cost Efficiency | ✅ Long-term savings | ⚠️ Frequent replacement |

Choose Tungsten Carbide if your mixer handles highly abrasive materials and impact is minimal.

Choose Steel if you need impact resistance, corrosion resistance, or lower initial cost.

For ultra-demanding applications, tungsten carbide coated steel blades can offer a balance between toughness and wear resistance.

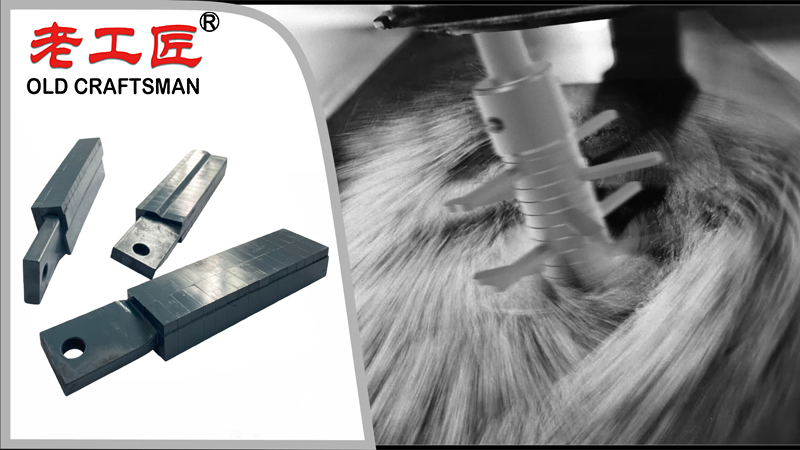

High-performance intensive mixers for carbide powder processing require blades that can withstand extreme mechanical stress and high temperatures while maintaining a sharp cutting edge over extended service life. To achieve this, blades are typically manufactured from high-strength, high carbon alloy steels or advanced corrosion resistant alloys. In highly abrasive and corrosive environments, duplex stainless steel or austenitic stainless steel grades with enhanced alloying elements are preferred for their superior tensile strength, excellent corrosion resistance, and balanced cost effectiveness. For applications involving even higher temperatures and severe wear, specialized heat resistant alloy steels with optimized carbon content and additional alloying elements deliver exceptional mechanical properties, prolonged durability, and reliable performance under the most demanding carbide mixing conditions.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding