The Problem with Traditional Scrapers in Mining Operations

Mining conveyor belt systems face extreme conditions that accelerate wear on conventional scrapers:

- Abrasive materials cause rapid deterioration

- Constant friction leads to frequent replacement needs

- Downtime for scraper changes reduces productivity

- Labor costs accumulate with repeated maintenance

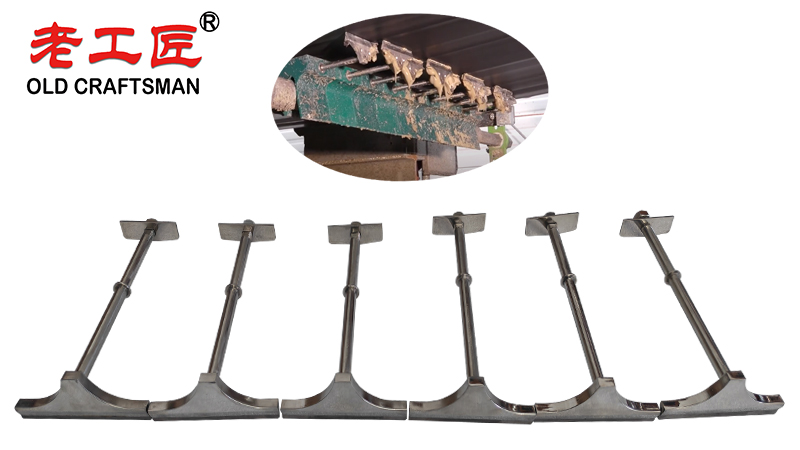

Carbide Scrapers: A Cost-Effective Solution

Tungsten carbide-tipped scrapers offer significant advantages for mining operations:

Extended Service Life

- 50-300% longer lifespan than traditional polyurethane or steel scrapers

- Exceptional wear resistance against abrasive materials

- Maintain effective cleaning performance for extended periods

Reduced Maintenance Costs

- Fewer replacement intervals mean lower parts costs

- Less frequent maintenance reduces labor expenses

- Minimized downtime increases overall productivity

Improved Belt Life

- More consistent cleaning reduces material carryback

- Prevents uneven wear patterns on belts

- Proper blade alignment maintained longer

Implementation Considerations

- Proper Installation: Ensure correct angle and pressure for optimal performance

- Regular Inspection: Check for wear patterns and adjust as needed

- Gradual Transition: Consider pilot testing on critical conveyors first

- Supplier Selection: Choose reputable manufacturers with mining experience

Cost-Benefit Analysis

While carbide scrapers have higher upfront costs, the total cost of ownership is typically lower due to:

- Reduced frequency of replacements

- Lower labor requirements

- Increased system uptime

- Extended belt life

Many mining operations report ROI within 6-12 months after switching to carbide scrapers, with ongoing savings throughout the scraper’s extended service life.

Advanced carbide scrapers represent a cost-effective upgrade that can significantly improve the efficiency and productivity of mining conveyor systems while reducing operational costs.

In the competitive precious metals mining industry across the United States, implementing a cost effective conveyor belt scraper is one of the smartest investments for long term operational efficiency. High quality belt scraper systems drastically reduce wear and tear on belt conveyors and roller conveyors, even in high temperature environments, while minimizing material carryback and spillage. By integrating these scrapers into a comprehensive preventative maintenance and predictive maintenance strategy, mining operations can significantly cut costs, avoid expensive unplanned downtime, and optimize their overall maintenance budget. The result is a smoother, more reliable material flow that directly improves efficiency and protects the bottom line for years to come.

Conclusion

Mining companies are adopting tungsten carbide scrapers because they offer longer service life, lower operational costs, and improved efficiency in abrasive and high impact conditions. This shift aligns with the industry’s push toward more durable and cost-effective mining tools.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding