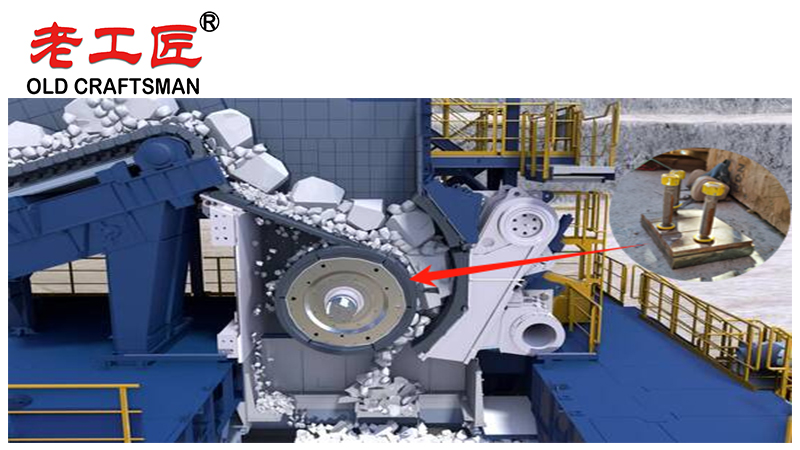

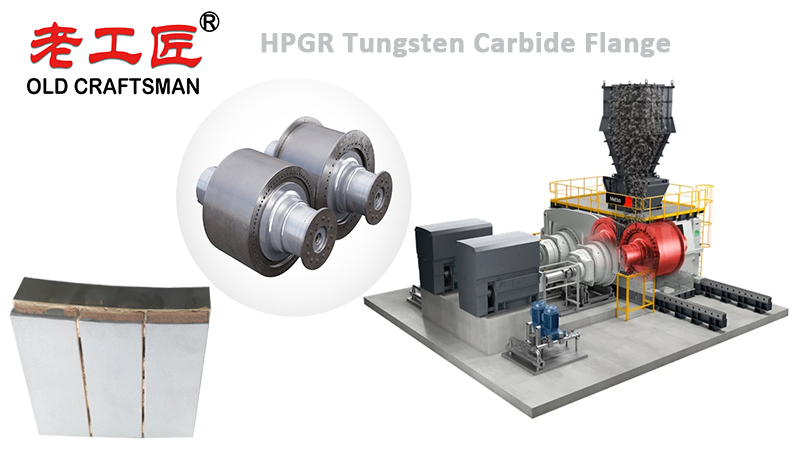

Exploring the wear resistance of mining High-Pressure Grinding Roll (HPGR) tungsten carbide flanges involves understanding their material properties, operational conditions, and failure mechanisms. HPGRs are critical in mineral processing for efficient comminution, and their flanges (or studs) endure extreme abrasive wear. Here’s a breakdown of key aspects:

1. Material Composition & Properties

- Tungsten Carbide (WC): Typically used as a wear-resistant material in HPGR flanges due to:

- High Hardness (HV 1500–2200) for abrasion resistance.

- Fracture Toughness (8–12 MPa√m) to withstand impact stresses.

- Cobalt (Co) Binder: Usually 6–12%, balancing hardness and toughness. Lower Co increases hardness but reduces toughness.

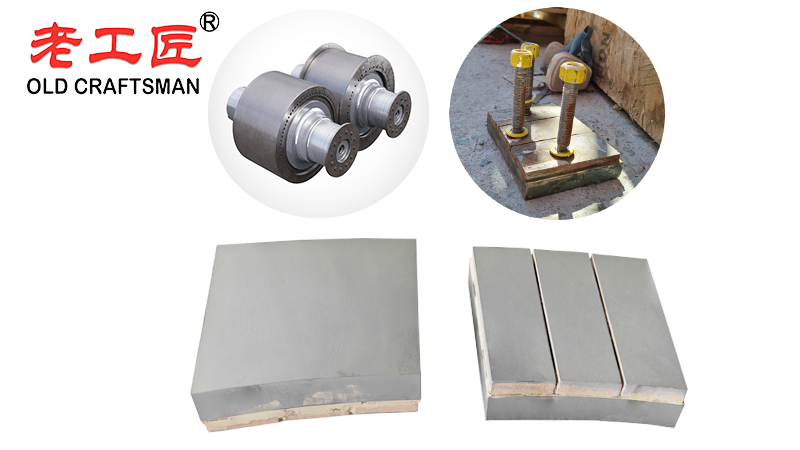

- Grades: Customized WC-Co grades are tailored for mining applications (e.g., fine grained WC for higher wear resistance).

2. Wear Mechanisms in HPGR Flanges

- Abrasive Wear: Dominant mechanism due to hard mineral particles (e.g., iron ore, diamonds) grinding against surfaces.

- Impact Wear: Cyclic loading from ore feed causes micro-cracking/spalling.

- Surface Fatigue: Repeated stress cycles lead to subsurface cracks.

- Corrosive Wear: Moisture/chemicals in ore may accelerate wear (minor role compared to abrasion).

3. Factors Influencing Wear Resistance

- Microstructure: Fine-grained WC with uniform Co distribution resists wear better.

- Load & Pressure: HPGRs operate at 50–250 MPa; higher pressures accelerate wear.

- Feed Material: Quartz (Mohs 7) causes more wear than softer ores.

- Operational Parameters: Roll speed, feed size, and moisture content affect wear rates.

- Design Geometry: Flange shape (e.g., stud height, spacing) impacts wear distribution.

4. Testing & Evaluation Methods

- Field Trials: Monitoring flange lifespan in real HPGR operations (e.g., tons processed before replacement).

- Lab Tests:

- Pin-on-Disc or Rubber Wheel Abrasion Test (ASTM G65) to simulate abrasion.

- Impact Testing (e.g., Charpy) for toughness evaluation.

- Microscopy (SEM/EDS): To examine wear scars, crack propagation, and binder extrusion.

5. Strategies to Enhance Wear Resistance

- Material Optimization:

- Use ultra-fine WC grains or gradient structures.

- Add secondary carbides (TaC, Cr₃C₂) to improve hardness/toughness.

- Surface Engineering:

- Coatings (e.g., diamond like carbon) to reduce friction.

- Laser Cladding for localized reinforcement.

- Design Improvements:

- Optimize flange layout to distribute wear evenly.

- Replace monolithic flanges with segmented designs for easier maintenance.

6. Industry Challenges & Innovations

- Cost vs. Performance: Balancing tungsten carbide grade cost with operational lifespan.

- Recycling: Reusing WC-Co scrap from worn flanges via powder metallurgy.

- Alternative Materials: Exploring ceramic metal composites (e.g., WC-Ni) for niche applications.

HPGR carbide flanges, typically manufactured from cemented carbide reinforced with high performance stainless steels or advanced corrosion resistant materials, are specifically engineered for extreme high temperature and high pressure wear applications in mineral processing. These components combine exceptional hardness, high strength, and superior wear resistance of the cemented carbide insert with the toughness and corrosion resistance of specially selected stainless steels or cast iron bases. The resulting hybrid material offers outstanding mechanical properties, including high tensile strength, elevated Young’s modulus, and the ability to withstand prolonged exposure to abrasive slurries and thermal cycling. Compared to conventional carbon steel solutions, cemented carbide studded rolls provide dramatically extended service life while maintaining structural integrity under the most demanding application requirements, making them the preferred choice for high performance grinding systems where both physical properties and long term resistance of a material are critical to operational efficiency and cost effectiveness. This unique combination has also influenced modern cutting tool design principles in other severe duty industries.

Conclusion

Mining HPGR tungsten carbide flanges exhibit exceptional wear resistance but require careful material selection and operational management. Advances in microstructure engineering and predictive wear modeling (e.g., DEM simulations) are key to extending service life in harsh mining environments.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding