The Core Problem: Carryback and Its Consequences

To understand the solution, we must first understand the primary cause of the wear: carryback.

Carryback is the small amount of material (ore, coal, dirt, etc.) that doesn’t fully discharge off the head pulley and sticks to the conveyor belt. This material then travels back on the return side of the belt. Carryback might seem insignificant, but it has a cascading effect of damage and cost:

- Belt Wear: The abrasive material trapped between the belt and return idlers acts like sandpaper, grinding away the belt’s top cover and weakening the carcass, leading to premature failure.

- Roller and Idler Damage: Carryback accumulates on idler rolls, causing them to seize and stop rotating. A stationary roller creates intense friction against the moving belt, burning through both the roller shell and the belt itself.

- Structural Damage: Accumulated piles of carryback can weigh down the structure, promote corrosion, and interfere with belt tracking and other components.

- Safety and Environmental Hazards: Spillage creates slippery walkways, a major safety risk. It also creates dust, which is an environmental and health hazard (e.g., silicosis).

- Increased Labor and Maintenance Costs: Constant cleanup requires significant man-hours and disrupts operations.

The Solution: How Carbide Scrapers Work

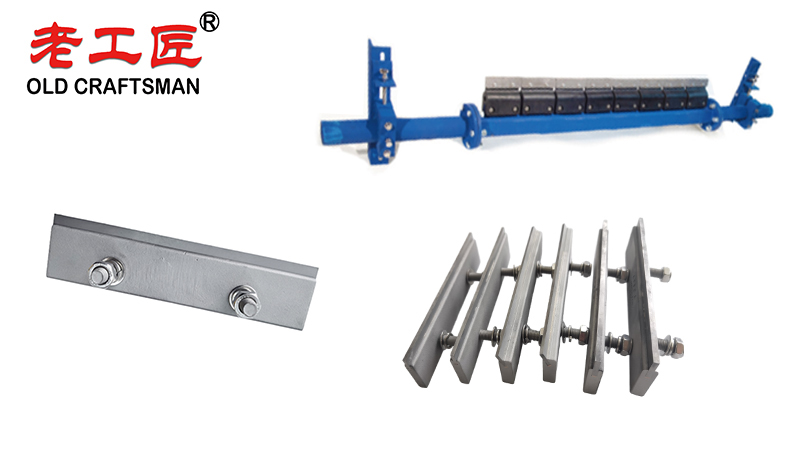

A carbide-tipped scraper, often called a primary belt cleaner, is mounted strategically at the head pulley, right where the belt changes direction. Its job is to physically remove carryback from the belt surface before it can travel back and cause damage.

Here’s how it specifically reduces wear and tear:

1. Superior Abrasion Resistance

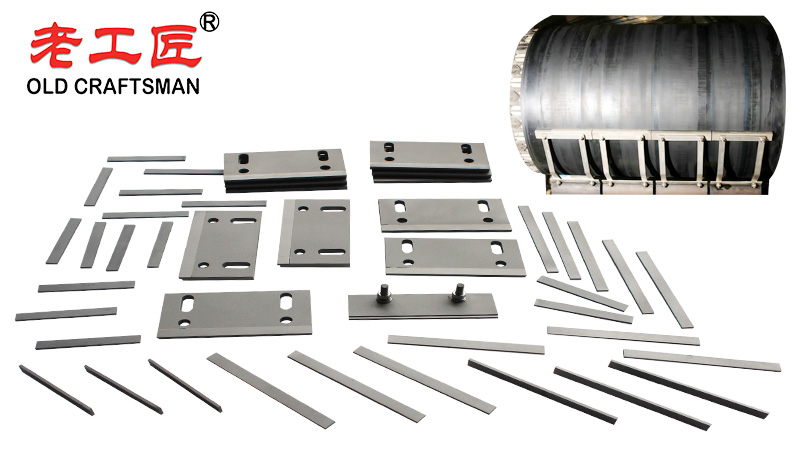

- The Material: The tips of these scrapers are made from tungsten carbide, one of the hardest materials available (second only to diamond on some scales). It is exceptionally resistant to abrasion from the rough, sharp-edged mining material.

- The Result: A standard steel or polyurethane blade will wear down quickly, losing its effectiveness and requiring frequent adjustment or replacement. A carbide blade maintains its sharp edge and profile for vastly longer periods, providing consistent cleaning performance.

2. Effective and Consistent Cleaning Action

- Precision Engineering: Carbide scrapers are not just chunks of metal. They are engineered with specific blade angles and mounting systems (often with tensioners like torsion or pneumatic arms) to apply the optimal amount of pressure against the belt.

- The Result: This consistent, firm pressure ensures near-total removal of sticky, abrasive material without damaging the belt itself. A clean belt is a belt that isn’t grinding itself to dust on its return journey.

3. Reduced Downtime and Maintenance

- Longevity: Because carbide is so wear resistant, these cleaners last months or even years before needing service, unlike other materials that may need weekly attention.

- The Result: This dramatically reduces unplanned downtime for cleaner maintenance and spillage cleanup. Maintenance crews can focus on more critical tasks.

4. Protection of Downstream Equipment

By eliminating carryback at the source, carbide scrapers protect the entire return side of the conveyor system:

- Return Idlers and Rollers: They remain clean and free-spinning, drastically extending their service life.

- Pulleys and Bearings: Prevent material from building up and causing misalignment or seal failure.

- Tail Pulleys: A clean belt won’t deposit material onto the tail pulley, which can cause belt mistracking and damage.

5. Improved Belt Tracking and Alignment

A belt running with a heavy, uneven load of carryback is more prone to mistracking. A consistently clean belt runs truer and puts less stress on its edges and the conveyor structure.

The “How-To” of Effectiveness: Proper Installation is Key

It’s crucial to note that a carbide scraper must be installed and maintained correctly to be effective and not become a source of wear itself.

- Location: Mounted as close to the point of material discharge as possible, while the material is still “lofted” on the belt and easier to remove.

- Blade Angle: The angle of the carbide tips is critical to scrape with the belt surface, not dig into it.

- Pressure: The tensioning system must apply enough pressure to clean effectively but not so much that it causes excessive wear on the blade or the belt. Modern systems are self-adjusting to compensate for blade wear.

- Multiple Blades: Often, a primary carbide scraper is used in conjunction with a secondary cleaner (e.g., a brush or polyurethane blade) to catch any remaining fines, creating a two-stage cleaning process for maximum efficiency.

Summary: The Direct Link to Reduced Wear & Tear

| Problem (Caused by Carryback) | How a Carbide Scraper Solves It |

|---|---|

| Abrasive Belt Wear | Removes the abrasive material (carryback) so it can’t grind the belt against the idlers. |

| Seized Idlers/Rollers | Prevents material buildup on idlers, keeping them spinning freely and reducing friction. |

| Pulley and Bearing Damage | Keeps the system clean, preventing material from interfering with mechanical components. |

| Structural Spillage | Eliminates the source of spillage, reducing cleanup costs and structural load. |

| Premature Component Failure | Extends the life of the entire conveyor system the belt, idlers, pulleys, and structure. |

In essence, a carbide scraper is a small, upfront investment that acts as a first and critical line of defense, protecting the much larger investments in the conveyor belt and its supporting components, thereby significantly reducing total wear and tear.

Conveyor systems work efficiently to move items in factories, warehouses, and mining operations, helping to reduce labor costs and increase productivity. Among the different types of conveyor systems including roller conveyors, chain conveyors, overhead conveyors, and belt conveyors each conveyor type is specifically designed for particular applications. In mining, for example, a high quality mining conveyor belt scraper is essential to keep the belt clean and running smoothly. For leather belts used in some specialized conveyors or chain conveyors, regular maintenance is important: first, clean your leather belt with a dedicated leather cleaner, then apply a small amount of leather conditioner using clean cloth and circular motions to keep it supple and long lasting. Overall, choosing the right conveyor type and maintaining it properly delivers a highly cost effective materials-handling solution.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding