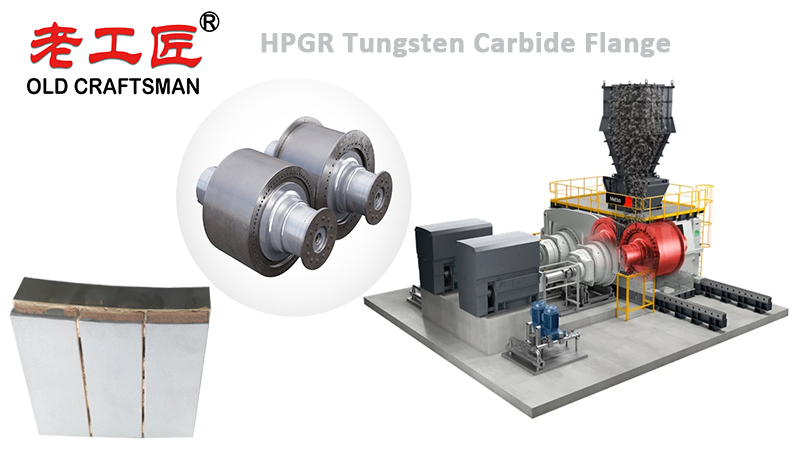

High-Pressure Grinding Rolls (HPGRs) are renowned for their energy efficiency and superior particle reduction in mining and aggregate operations. However, their Achilles’ heel has traditionally been the flanges the outer edges of the rolls that contain the grinding bed.

The key to unlocking maximum uptime and profitability from an HPGR lies in upgrading from traditional steel flanges to Tungsten Carbide Hardfaced or Clad Flanges.

The Problem: Why Standard Steel Flanges Cause Downtime

Standard alloy steel flanges are susceptible to rapid and severe wear from two primary mechanisms:

- Abrasive Wear: The primary grinding action. The processed material (often extremely abrasive ore like iron, gold, or copper) constantly scours the flange surface.

- Impact Wear: As the feed material enters the nip point between the rolls, larger chunks can impact the flanges with significant force, causing deformation, cracking, and spalling.

The Result: Steel flanges wear down quickly, losing their height and structural integrity. This leads to a cascade of problems:

- Loss of Containment: Worn flanges can no longer contain the feed material effectively. This causes edge spillage, where uncompressed material flows around the sides of the rolls instead of being pressed into the sheet. This represents a direct loss of throughput and efficiency.

- Uneven Roll Wear: The roll body, typically protected by tungsten carbide studs, wears much slower than the steel flanges. This creates a “dished” or “concave” profile on the roll, drastically reducing grinding efficiency and increasing power consumption.

- Frequent Stops for Maintenance: Rolls must be pulled from the machine for flange repair or replacement. This process is incredibly time consuming, labor intensive, and halts the entire crushing circuit.

- Damage to Other Components: Spillage can accelerate wear on seals, bearings, and other peripheral equipment, leading to even more frequent and unexpected downtime.

The Solution: Tungsten Carbide Flanges

Tungsten carbide (WC) is a ceramic metal composite (a cermet) known for having exceptional hardness and wear resistance second only to diamond.

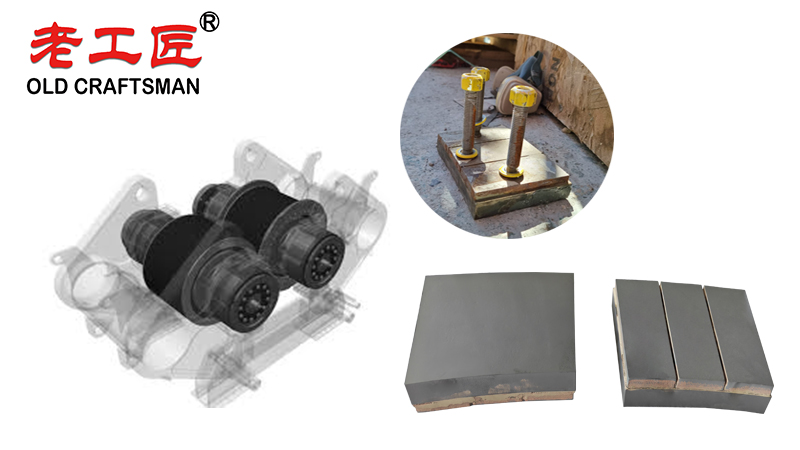

Applying a layer of tungsten carbide to the flange surface fundamentally changes its wear characteristics. This is typically done via:

- Hardfacing (Welding): Using specialized techniques like PTA (Plasma Transferred Arc) welding to deposit a thick, wear resistant layer of tungsten carbide onto the steel flange substrate.

- Cladding: Bonding a pre-formed plate of tungsten carbide composite to the flange surface.

How Tungsten Carbide Flanges Drastically Reduce Downtime

| Downtime Factor | Steel Flange Problem | Tungsten Carbide Flange Solution | Result |

|---|---|---|---|

| Wear Rate | High wear rate. Requires replacement every 1-6 months. | Extremely low wear rate. Service life extended to 12-24 months or even longer. | Massive increase in Mean Time Between Failure (MTBF). Fewer scheduled maintenance stops. |

| Containment | Rapidly loses height, leading to constant spillage. | Maintains profile height for vastly longer. Contains the grinding bed effectively. | Consistent throughput, improved product yield, and higher efficiency. No loss of production to spillage. |

| Roll Profile | Wears faster than the roll body, creating a dished profile. | Wear rate is matched to the tungsten carbide studs on the roll body. Maintains a flat, optimal grinding profile. | Sustained grinding efficiency, lower specific energy consumption (kWh/ton). |

| Unexpected Failure | Prone to impact damage, cracking, and catastrophic failure. | Highly resistant to impact and abrasion. Fails predictably through slow, even wear. | Eliminates unplanned downtime. Maintenance can be planned well in advance during scheduled circuit stops. |

| Maintenance Time | Entire roll cartridge often needs to be pulled for repair. | In some cases, can be built up with wear resistant weld in place (though specialized techniques are needed). | Reduces the duration of maintenance events when they do occur. |

Key Considerations for Implementation

Switching to tungsten carbide flanges isn’t just a simple parts swap; it’s a strategic upgrade.

- Capital Cost vs. Operational Cost (TCO): The initial investment in tungsten carbide flanges is significantly higher than steel flanges. However, the Total Cost of Ownership (TCO) is almost always lower. This is calculated by factoring in the cost of replacement parts, labor for changes, and most importantly the value of lost production during downtime.

- Professional Application: The application of tungsten carbide requires expert knowledge. Improper welding techniques can lead to cracking and delamination. It must be performed by specialists.

- Compatibility: Ensure the flange upgrade is compatible with your specific HPGR model and roll design.

- Inspection and Monitoring: Even with tungsten carbide, regular visual inspection and measurement of flange height during routine maintenance are crucial to plan for eventual re-application or replacement.

Our company offers a wide range of premium HPGR carbide flanges and tungsten carbide wear parts specifically designed for high pressure grinding rolls (HPGR) in the mining and cement industries.

Manufactured from the finest cemented carbide (tungsten carbide grades), these components deliver exceptional wear resistance, corrosion resistance, high strength, and outstanding performance under high pressures and high temperatures, significantly extending service life and reducing downtime.

By choosing our tungsten carbide wear parts, you benefit from recurring or deferred purchase options with flexible pricing, frequency, and dates tailored to your needs. We will charge your selected payment method at the prices, frequency, and dates listed at checkout. By continuing, you agree to the cancellation policy and authorize automatic payments until cancellation.

Conclusion: The Bottom Line

Investing in tungsten carbide flanges for your HPGR is not an expense; it is a strategic investment in reliability and productivity.

By matching the incredible wear resistance of the flanges to that of the roll body’s studs, you create a cohesive system that maintains its efficiency and integrity for thousands of additional operating hours. The dramatic reduction in both the frequency and duration of maintenance stops directly translates to higher availability, more tons processed, and ultimately, a stronger bottom line.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding