Executive Summary

Tungsten carbide blades are essential for heavy duty intensive mixers because they provide an unparalleled combination of extreme hardness, wear resistance, and structural integrity. This allows them to withstand the abrasive, high impact, and high temperature conditions of intensive mixing processes far better than any other blade material, leading to superior product consistency, reduced downtime, and lower long term operational costs.

The Challenging Environment of an Intensive Mixer

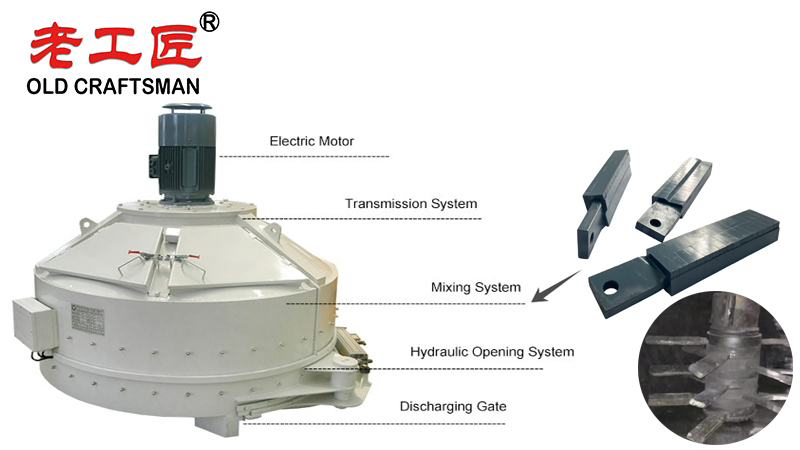

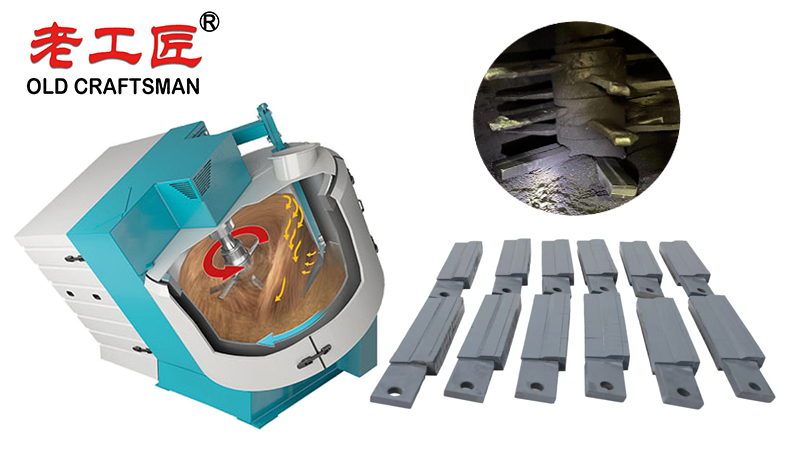

To understand why the blade material is so critical, consider what happens inside a heavy duty intensive mixer (e.g., a sigma blade mixer, ploughshare mixer, or double arm mixer). These mixers are designed for the toughest jobs:

- High Viscosity Materials: They process thick pastes, slurries, doughs, and compounds filled with abrasive powders (e.g., ceramics, minerals, glass fiber, metal powders).

- High Shear and Impact: The blades must forcefully plough through, knead, and shear the material to achieve a homogeneous mix. This generates significant mechanical stress and impact forces on the blades.

- Abrasive Wear: Many ingredients are highly abrasive. For example, silica, carbon black, and mineral fillers act like sandpaper, constantly eroding the blade surface.

- High Pressure and Temperature: The intense mechanical energy input generates substantial heat, often requiring jacketed cooling. The blades operate under high pressure and at elevated temperatures.

- Corrosive Environments: Some mixtures may be acidic or otherwise corrosive, adding a chemical attack element to the physical wear.

Why Tungsten Carbide is the Superior Choice

Tungsten carbide (WC) is a composite material made of tungsten carbide particles cemented together with a binder, usually cobalt. This structure gives it properties that are perfectly suited to combat the challenges above.

1. Exceptional Hardness and Wear Resistance

- Property: Tungsten carbide is one of the hardest materials available for industrial applications, significantly harder than hardened tool steel. It ranks about 9 on the Mohs scale of mineral hardness (diamonds are a 10).

- Benefit: This extreme hardness makes it highly resistant to abrasive wear. The abrasive particles in the mix have a much harder time scratching, gouging, or eroding the blade surface. A steel blade would quickly lose its precise geometry, while a carbide blade maintains its edge profile for vastly longer periods.

2. Superior Strength and Resistance to Deformation

- Property: While incredibly hard, tungsten carbide also has a very high compressive strength meaning it resists bending, bulging, or deforming under the immense pressures found in an intensive mixer.

- Benefit: The blades maintain their exact shape and clearance with the mixer wall. This is critical for maintaining consistent shear rates and mixing efficiency. A deformed steel blade would lead to poor product quality and potential mechanical failure.

3. Enhanced Corrosion and Chemical Resistance

- Property: The tungsten carbide cobalt matrix is generally more chemically inert than iron based steels, offering better resistance to many corrosive chemicals.

- Benefit: In processes involving acids, alkalis, or other reactive substances, carbide blades degrade much more slowly than standard steel blades, preventing pitting and corrosion that can weaken the blade and contaminate the product.

4. High Temperature Stability

- Property: Tungsten carbide retains its hardness and strength at much higher temperatures than steel, which can soften (lose temper) as temperatures rise.

- Benefit: Since intensive mixing generates heat, this property ensures the blades do not soften and wear faster during operation. They perform consistently throughout the batch cycle.

The Tangible Benefits for Your Operation

Using tungsten carbide blades translates directly into operational advantages and cost savings:

- Dramatically Extended Lifespan: This is the most significant benefit. A tungsten carbide blade can last 10 to 25 times longer than a hardened steel blade in the same application. This eliminates frequent changeovers.

- Reduced Maintenance and Downtime: Fewer blade replacements mean less downtime for maintenance. This increases overall equipment availability and production throughput.

- Consistent Product Quality: Because the blade geometry remains unchanged for thousands of hours, the mixing action and therefore the product quality remains consistent from the first batch to the last batch before a changeout. There is no gradual degradation in mix homogeneity.

- Lower Long-Term Cost of Ownership: While the initial purchase price of a tungsten carbide blade is higher than a steel blade, the dramatically longer lifespan results in a much lower cost-per-hour or cost-per-ton-mixed. This makes it the more economical choice over time.

- Reduced Contamination: The extreme wear resistance means the blade itself sheds very little material, minimizing metallic contamination in your sensitive product (a critical factor in industries like pharmaceuticals, food, and advanced ceramics).

Comparison to Alternative Materials

| Material | Pros | Cons | Best For |

|---|---|---|---|

| Tungsten Carbide | Extreme hardness, excellent wear resistance, long life, maintains geometry. | Higher initial cost, can be brittle if impacted. | Essential for heavy duty, highly abrasive applications. |

| Hardened Tool Steel | Good strength, impact resistant, lower cost. | Wears quickly in abrasive environments, loses geometry. | Less abrasive, general purpose mixing. |

| Stainless Steel | Good corrosion resistance. | Softer, poor wear resistance. | Corrosive but non-abrasive applications (e.g., food, pharmaceuticals without fillers). |

| Ceramic Coatings | Very hard surface, good wear resistance. | Can chip or spall under impact, complex repair. | Situations where a full carbide blade is cost prohibitive. |

Note on Brittleness: While tungsten carbide is hard, it is more brittle than steel. This means it is susceptible to chipping or cracking from severe *impact (e.g., hitting a metal tool accidentally left in the mixer). Proper handling and operation mitigate this risk.

Our carbide-intensive mixers feature high performance double arm blades made from premium stainless steel, tool steel, knife steel, and specially selected carbon steel alloys. Through an optimized production process with strict heat treatment, and rigorous quality control at every stage, we ensure extremely high wear resistance and a cutting-edge performance in even the most demanding mixing processes. Whether working with mild steel components or advanced high alloy steels, the result is always the same: a wide range of consistent, high quality products that deliver outstanding durability and efficiency. When it comes to heavy duty mixing and cutting tooling, our solutions protect your bottom line by minimizing downtime and maximizing output.

Carbide-intensive mixers rely on blades with exceptional corrosion resistance and a wide range of mechanical properties to withstand the aggressive, high shear environment of modern mixing processes. Manufactured from high performance medium carbon steel or high carbon steel grades, these blades typically feature increased carbon content combined with strategic alloying elements, resulting in high alloy steels that maintain strength and a razor-sharp cutting edge even under high temperature conditions. Through precisely controlled heat treatment, the steel alloys are heat treated to optimize hardness, toughness, and wear resistance, delivering superior overall high strength and long service life comparable to premium cutting tools making them the preferred choice for intensive, high performance blade mixers in demanding industrial applications.

Conclusion

For heavy duty intensive mixers processing abrasive, high viscosity materials, tungsten carbide blades are not just an upgrade; they are a necessity for efficient, reliable, and economical operation. They are the definitive solution for maximizing uptime, ensuring product consistency, and minimizing the total cost of ownership in the most demanding mixing environments. The investment in tungsten carbide technology pays for itself many times over through unparalleled durability and performance.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding