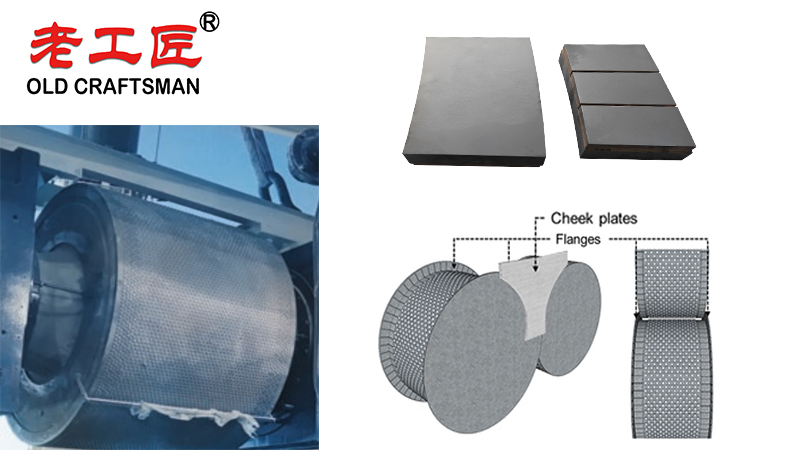

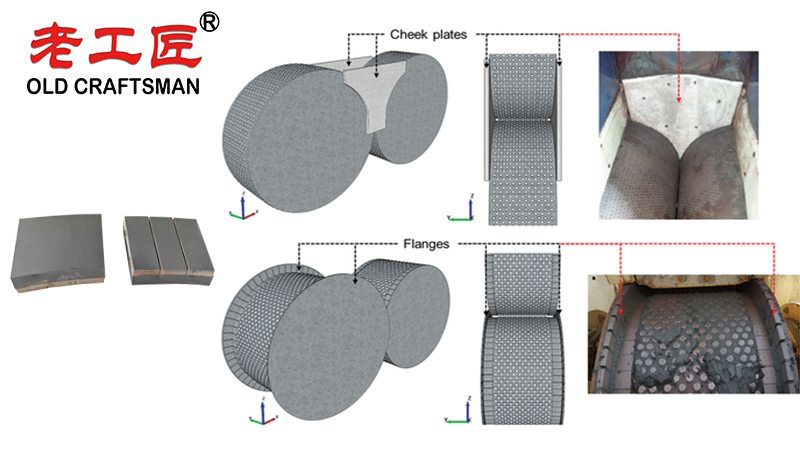

In the demanding world of mineral processing, High Pressure Grinding Rolls (HPGRs) have become a cornerstone technology for efficient comminution (crushing and grinding). They operate by compressing a bed of ore between two counter rotating rolls, exerting immense pressure to cause particle breakage.

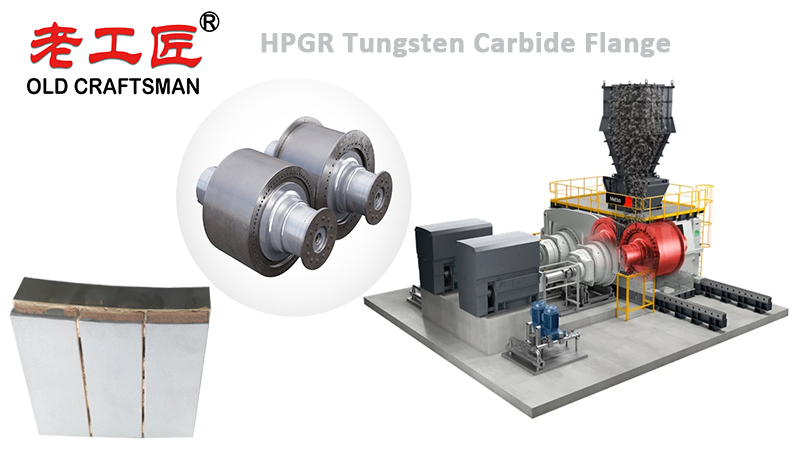

At the heart of this punishing process are the flanges the raised edges on the sides of the rolls. Their job is critical: to contain the feed material and build the high pressure bed necessary for efficient grinding. This role makes them subject to extreme abrasion, impact, and fatigue stresses. While the roll body might be made of a tough alloy steel, the flanges are increasingly being protected or entirely constructed with Tungsten Carbide (WC). This is where the combination of unparalleled strength and exceptional resilience comes into play.

1. Strength: The Unyielding Hardness

The “strength” of Tungsten Carbide flanges primarily refers to their compressive strength and hardness, which are orders of magnitude greater than hardened steel.

- Extreme Hardness: Tungsten carbide is a composite material, consisting of hard tungsten carbide particles (a 9 on the Mohs scale, compared to a diamond which is a 10) bonded together in a tough cobalt or nickel matrix. This gives it a Vickers Hardness (HV) that can exceed 1500, compared to approximately 800 for the hardest steels. This immense hardness is the primary defense against abrasive wear.

- Superior Compressive Strength: Tungsten carbide has one of the highest compressive strength ratings of any alloy used in industrial applications. It can withstand the tremendous pressures (often exceeding 200-300 MPa) generated in the grinding zone without deforming or fracturing. This allows the flanges to maintain their precise geometry and containment function far longer than steel alternatives.

Result: This strength directly translates to a massive reduction in wear rates. Tungsten carbide flanges can last 5 to 10 times longer than their steel counterparts. This drastically reduces downtime for flange replacement and maintenance, leading to significantly higher equipment availability and throughput.

2. Resilience: The Ability to Withstand Punishment

“Resilience” in this context refers to the material’s ability to absorb energy, resist crack propagation, and perform under cyclic loading without failing. While extremely hard materials can sometimes be brittle, modern tungsten carbide grades are engineered for resilience.

- Toughness (Fracture Resistance): The cobalt/nickel binder provides crucial toughness. It acts as a metallic “glue” that allows the material to absorb impact energy from uncrushable objects (like tramp metal or very hard ore pieces) without shattering. Advanced manufacturing techniques create a fine, uniform microstructure that prevents cracks from easily spreading.

- Fatigue Resistance: HPGR operation involves constant, cyclical loading as ore passes through the rolls. Steel flanges can suffer from plastic deformation and fatigue cracking over time. Tungsten carbide’s high fatigue strength allows it to endure these millions of cycles with minimal damage, maintaining its structural integrity.

- Thermal Stability: The grinding process generates significant heat. Tungsten carbide retains its hardness and strength at elevated temperatures much better than steel, which can soften and lose its protective properties when hot.

Result: This resilience means the flanges are not just hard, but also robust and reliable. They are far less likely to suffer from catastrophic chipping, spalling, or breakage due to unexpected impact events, ensuring operational stability and protecting the more expensive roll bodies from damage.

The Perfect Combination: Why It Matters for HPGRs

The synergy of strength and resilience in tungsten carbide flanges creates transformative benefits for mining operations:

- Dramatically Extended Service Life: The most direct benefit. Longer lasting flanges mean fewer change-outs, reducing maintenance costs, labor hours, and inventory requirements for spare parts.

- Increased Availability and Throughput: Less downtime for maintenance translates directly to more hours of operation and higher tons processed per year, boosting overall plant productivity.

- Consistent Grinding Performance: Worn steel flanges lead to a loss of pressure in the grinding bed, reducing efficiency and product quality (particle size distribution). Tungsten carbide flanges maintain their profile for much longer, ensuring stable and efficient grinding performance throughout their life.

- Reduced Total Cost of Ownership (TCO): While the initial investment in tungsten carbide flanges is higher than steel, the vastly extended lifespan and improved operational efficiency result in a significantly lower cost per ton of ore processed.

- Enhanced Protection: A resilient tungsten carbide flange acts as a superior shield, protecting the underlying roll structure and the mechanical components of the HPGR from damage caused by escaped material or direct impact.

High Performance Grinding Rolls (HPGR) widely used in the mining and cement industries rely heavily on carbide studded flanges to resist extreme abrasive wear. These flanges are typically manufactured from high quality wear resistant carbide inserts precisely pressed or brazed into a base flange body made of heat treated carbon steel or corrosion resistant stainless steel, depending on the operating environment.

The carbide studs provide exceptional wear resistance even under high temperature conditions (often exceeding 300–500 °C during operation), while maintaining mechanical properties such as high yield strength and ultimate tensile strength over a wide range of operating parameters. The raw material for the carbide is tungsten carbide (WC) with cobalt binder; careful control of carbon content and alloying elements ensures the optimal combination of hardness, toughness, and corrosion resistance.

The steel base material is usually a low alloy or medium carbon steel that is heat treated (quenched and tempered) to achieve yield strength typically between 600–1000 MPa and ultimate tensile strength of 800–1200 MPa at room temperature, providing the necessary structural support while the carbide surface handles the primary wear duty.

This composite design delivers high performance, long lasting HPGR rolls that significantly outlast conventional hardfacing solutions, making them the preferred choice for cutting tools and high pressure comminution applications demanding both wear resistant and corrosion resistant properties under severe service conditions.

Conclusion

The move to Tungsten Carbide Flanges in mining HPGRs is a prime example of selecting the right material for an extreme environment. By combining the unyielding strength needed to resist abrasive wear with the engineered resilience to withstand impact and fatigue, they solve the primary failure mode of the HPGR grinding process. This powerful combination is not just an incremental improvement but a step change technology that drives productivity, lowers operating costs, and maximizes the return on investment for modern mineral processing operations.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding