In the harsh environment of mining, conveyor belts are the lifelines for transporting bulk materials like coal, ore, and aggregates. However, a significant and common hazard associated with these systems is material carryback the sticky, often abrasive residue that clings to the belt after it passes over the head pulley and fails to discharge completely.

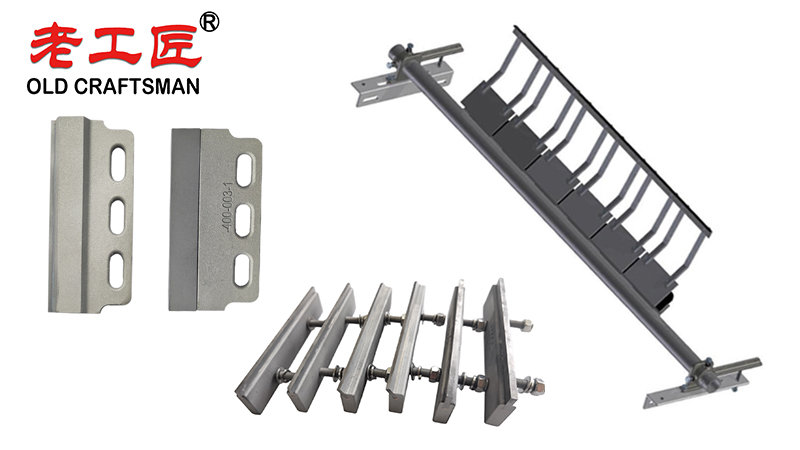

A secondary tungsten scraper is a robust, engineered blade system installed on the return side of the conveyor belt (after the primary cleaner) to remove this residual carryback. Its role in enhancing workplace safety is multi faceted and critical.

Here’s how they contribute to a safer mining operation:

1. Elimination of Slip, Trip, and Fall Hazards (The Primary Safety Benefit)

This is the most direct and impactful safety improvement.

- The Problem: Without an effective secondary cleaner, carryback material falls off the return side of the belt along the entire conveyor length. This accumulation creates piles of loose, often unstable material on walkways, access platforms, and around conveyor structures.

- The Solution: A tungsten-tipped secondary scraper efficiently removes up to 90-95% of remaining carryback at the source (the head pulley). This prevents it from being dispersed throughout the plant.

- The Safety Outcome: Cleaner walkways and structures drastically reduce the risk of miners slipping on debris or tripping over accumulated piles, which are leading causes of injuries in mining operations.

2. Reduction of Airborne Dust and Improved Respiratory Safety

- The Problem: As dried carryback falls from the moving return belt, it can become airborne. In mining, this dust can contain silica (a known carcinogen causing silicosis), coal dust (a combustibility hazard and cause of black lung disease), or other harmful particulates.

- The Solution: By removing the material while it is still damp and consolidated at the pulley, the scraper prevents it from being ground into fine dust and dispersed into the air as the belt travels over idlers.

- The Safety Outcome: Improved air quality protects workers from serious long-term respiratory illnesses and reduces the risk of dust explosions. It also improves visibility around equipment.

3. Prevention of Structural Damage and Associated Hazards

- The Problem: Accumulated carryback is heavy and abrasive. When it builds up under the conveyor, it can:

- Put stress on structures, leading to potential fatigue and failure.

- Jam rotating components like tail pulleys, return idlers, and rollers. A seized roller can create extreme friction, leading to a friction fire a catastrophic event underground.

- Cause belt mistracking and damage, which can lead to sudden and dangerous belt failures.

- The Solution: The secondary scraper prevents this buildup, ensuring idlers and pulleys rotate freely and the structure remains clear.

- The Safety Outcome: It mitigates the risk of structural collapse, equipment seizure, and fire, creating a more predictable and stable operating environment.

4. Reduction in Manual Cleaning Tasks (Lockout/Tagout Exposure)

- The Problem: In systems without effective scrapers, workers are often required to perform dangerous manual cleaning. This involves using bars, shovels, or high pressure water jets to remove built-up material from operating or recently stopped equipment.

- The Solution: An automatic, effective secondary scraper performs this job continuously without human intervention.

- The Safety Outcome: This drastically reduces the need for workers to be in close proximity to moving machinery (nip points, rollers, belts), eliminating exposure to entanglement and crushing hazards. It also reduces the frequency of requiring Lockout/Tagout (LOTO) procedures for cleaning, which, while safe, always carries some inherent risk during the application and removal process.

5. Why “Tungsten” Specifically Enhances Safety and Performance

The choice of tungsten carbide as the blade material is not arbitrary; it directly contributes to the reliability and safety of the system:

- Exceptional Wear Resistance: Tungsten is incredibly hard and abrasion resistant, far outperforming polyurethane or steel scrapers. This means it maintains a consistent blade edge and effective cleaning performance for much longer periods.

- Consistent Performance: A worn scraper is an ineffective scraper. Because tungsten lasts longer, the system doesn’t degrade quickly, providing reliable safety benefits without constant adjustment or replacement.

- Reduced Maintenance Frequency: Longer service intervals mean maintenance personnel are required to inspect, adjust, or replace the scraper less often. This reduces their exposure to hazards at the head pulley, which is often a confined and elevated space.

Summary: The Safety Chain Reaction

The implementation of a secondary tungsten scraper creates a positive chain reaction for safety:

Effective Scraper → Reduced Carryback →

- Cleaner Walkways → Fewer Slips/Trips/Falls

- Less Airborne Dust → Improved Respiratory Health & Visibility

- No Material Buildup → Reduced Equipment Damage & Fire Risk

- No Manual Cleaning → Reduced Exposure to Moving Machinery

In conclusion, a secondary tungsten scraper is far more than just a maintenance tool to protect the belt. It is a fundamental engineering control designed to proactively eliminate hazards at their source, making it a crucial component for any safety focused mining operation.

The mining conveyor belt scraper operates in one of the harshest work environments imaginable, where air quality is often severely compromised by large amounts of respirable dust and silica particles. These high quality health problems including silicosis, lung cancer, and chronic obstructive pulmonary disease make airborne hazardous materials a constant threat. Extreme temperatures, high humidity, poor ventilation, and potential fire hazards from frictional heat or combustible dust further worsen the environmental conditions.

Despite being a powerful tool for belt cleaning that significantly improves efficiency and reduces material carryback and spillage on construction sites and mining operations, the belt scraper itself can generate additional airborne contaminants if not properly maintained. For this reason, wearing a respirator that has passed a proper fit test remains the last critical line of defense to protect workers from inhaling dangerous particles, ensuring both their long term health and safe continuation of operations in these challenging settings.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding