Here’s a detailed explanation of how tungsten carbide blades reduce wear in intensive mixers, breaking down the “why” and the “how.”

The Problem: The Extreme Environment of an Intensive Mixer

First, it’s crucial to understand the challenges that mixer blades face. Intensive mixers (like paddle mixers, plough shear mixers, or Banbury mixers) are designed to blend tough, abrasive, and sometimes corrosive materials. Common examples include:

- Ceramic Powders: Alumina, silicon carbide

- Metal Powders: For powder metallurgy

- Minerals: Sand, silica, cement

- Reinforcing Fillers: Carbon black, glass fibers

- Pharmaceuticals: Some active ingredients and excipients

In these mixers, the blades (or rotors) are subjected to several destructive mechanisms simultaneously:

- Abrasive Wear: Hard, sharp particles scrape and micro-cut the blade surface, like sandpaper.

- Adhesive Wear: Under high pressure and temperature, material can temporarily weld to the blade surface and then be torn away, taking blade material with it.

- Impact Wear: Agglomerates or dense chunks of material can cause chipping or deformation at the blade’s leading edge.

- Corrosion: Some materials or cleaning agents can chemically attack the blade.

Standard steel blades, even hardened ones, wear down quickly in these conditions. This wear leads to:

- Increased Downtime: Frequent stops for blade replacement.

- Inconsistent Product Quality: As blades wear, their shape changes, altering the mixing action and resulting in uneven batches.

- Contamination: Worn blade material (iron/steel) enters the product mix.

- Higher Operating Costs: Constant replacement of blades and lost production time.

The Solution: Tungsten Carbide’s Superior Properties

Tungsten carbide (WC) is a ceramic-metallic composite (a “cermet”) made of tungsten carbide particles bonded together with a cobalt or nickel metal binder. This combination gives it a set of properties that are almost perfectly suited to combat the wear in intensive mixers.

Here’s how its key properties directly address the problem:

| Property of Tungsten Carbide | How It Reduces Wear in Mixer Blades |

|---|---|

| 1. Extreme Hardness | This is the most critical property. Tungsten carbide is significantly harder than hardened steel (often 2-3 times harder on the Rockwell C scale). This hardness makes it highly resistant to abrasive wear. The abrasive particles have a much harder time scratching or cutting into the blade surface. |

| 2. High Compressive Strength | Tungsten carbide can withstand immense pressure without deforming. This is vital for resisting impact wear and preventing the blade’s leading edge from being battered and rounded off over time. It maintains its precise geometry. |

| 3. Excellent Wear Resistance | This is a result of its hardness and strength. Tungsten carbide parts have a service life that can be 10 to 100 times longer than steel parts in the same application. This directly translates to less downtime and lower maintenance costs. |

| 4. Good Corrosion Resistance | While not as corrosion resistant as some specialty alloys, the cobalt bonded tungsten carbide offers reasonable resistance to many chemicals, providing an advantage over plain steel in mildly corrosive environments. |

How Tungsten Carbide is Applied to Blades

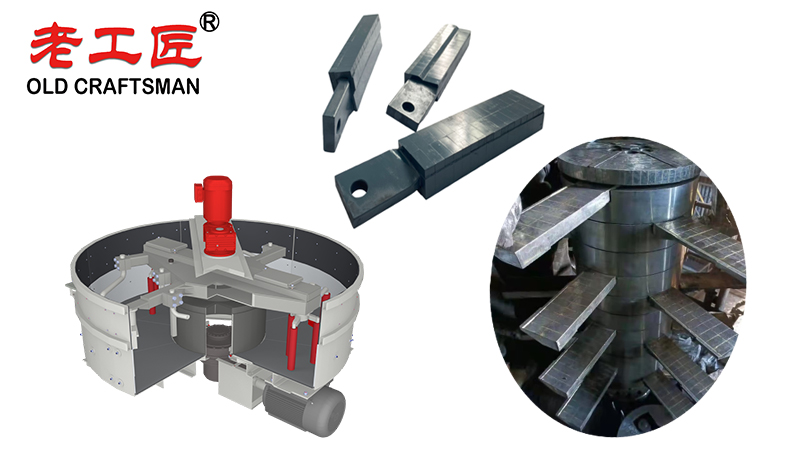

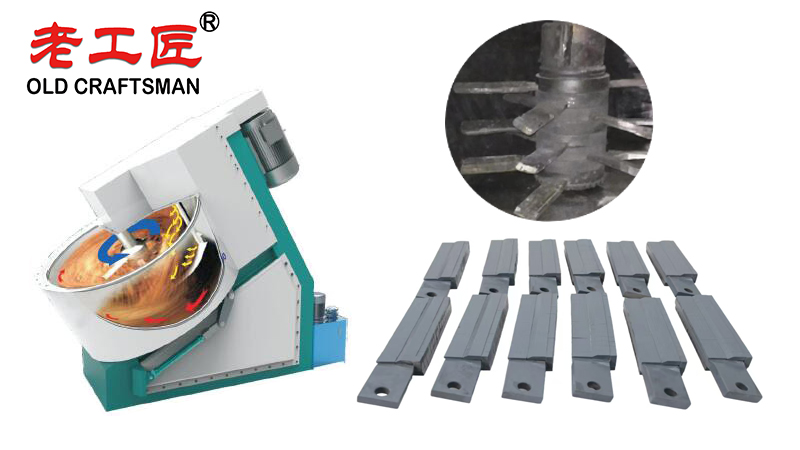

Tungsten carbide isn’t typically used to make the entire blade because it is brittle and expensive. Instead, it is strategically applied to the high-wear areas of a tough, steel blade body. The two most common methods are:

- Tungsten Carbide Overlay (Hardfacing/Welding):

- A layer of tungsten carbide weld wire or rod is deposited onto the critical surfaces of the steel blade, especially the leading edges and tips.

- This creates a thick, wear resistant “armor” that protects the underlying steel.

- Analogy: It’s like putting an extremely durable, replaceable “shield” on the parts of the blade that take the most punishment.

- Tungsten Carbide Tiles (Mechanically Attached):

- Pre-fabricated tiles or inserts of tungsten carbide are brazed (a high temperature soldering process) or mechanically fastened to the steel blade.

- This method allows for the use of very high grade tungsten carbide in specific shapes and patterns optimized for the material flow.

Left: Blade with a tungsten carbide overlay on the leading edge. Right: Blade with tungsten carbide tiles attached.

Summary of Benefits: The Bottom Line

By using tungsten carbide on mixer blades, operators achieve:

- Dramatically Extended Blade Life: The primary benefit. Blades last for months or years instead of weeks, drastically reducing replacement frequency.

- Reduced Maintenance Downtime: Fewer blade changes mean the mixer stays in production longer, increasing overall equipment effectiveness (OEE).

- Consistent Mixing Performance: Because the blade profile doesn’t change significantly over time, every batch is mixed with the same shear and action, ensuring product quality and consistency.

- Lower Contamination Risk: The extreme wear resistance means very little blade material is shed into the product mix.

- Improved Cost-Efficiency: Although the initial cost is higher, the total cost of ownership is much lower due to reduced downtime, labor, and replacement part costs.

High-performance carbide intensive mixers equipped with specially designed blades are capable of withstanding extremely high temperatures and severe abrasive conditions during demanding production processes. When machining abrasion-resistant stainless steel and high quality tool steel, these cutting tools deliver exceptional long term durability, minimal types of wear, and consistently low surface roughness, ensuring superior product quality and significantly reduced quality issues. Thanks to advanced heat treatment of the raw material and optimized manufacturing processes, customers achieve higher throughput, lower operating costs, and outstanding cost effective performance in real-time operations, ultimately leading to maximum customer satisfaction.

In conclusion, tungsten carbide reduces wear in intensive mixers by providing a surface that is orders of magnitude more resistant to the abrasive, adhesive, and impact forces that quickly destroy conventional steel blades. It is a prime example of using advanced materials engineering to solve severe industrial wear problems.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding