The impact of tungsten carbide scrapers on conveyor belt mining productivity is profoundly positive and multifaceted. While their primary function is belt cleaning, their effectiveness directly translates into significant gains in safety, operational efficiency, equipment longevity, and cost reduction. They are not merely a maintenance component but a critical productivity enhancing technology.

The Core Problem: Carryback

To understand the impact, we must first understand the problem they solve: carryback.

Carryback is the residual material that sticks to the conveyor belt after it passes the discharge point. This material falls off along the return strand, creating a cascade of operational inefficiencies:

- Spillage: Material piles up along the conveyor path.

- Belt Mistracking: Uneven material buildup can pull the belt off course.

- Roller Damage: Accumulated material hardens, causing idler rollers to seize and wear prematurely.

- Safety Hazards: Spillage creates slip-and-fall risks and requires manual cleanup, exposing workers to moving equipment.

- Increased Labor Costs: Significant man-hours are spent shoveling and cleaning up spillage.

How Tungsten Carbide Scrapers Work

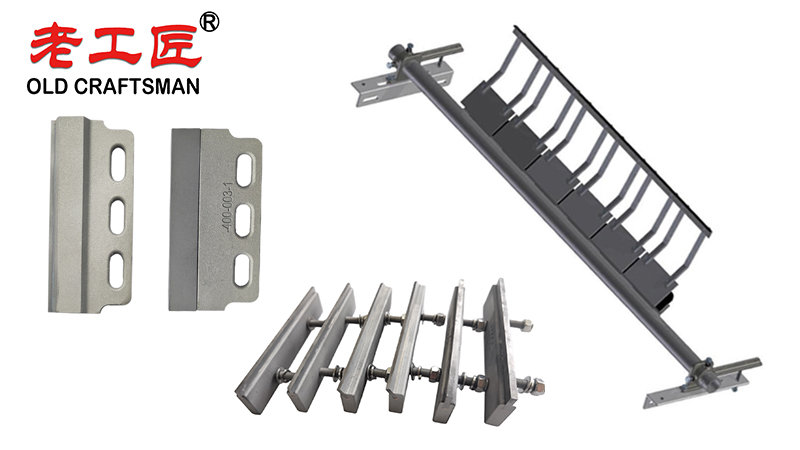

Tungsten carbide scrapers, often in the form of pre-tensioned polyurethane blades embedded with tungsten carbide tiles, are primary cleaners installed at the head pulley. Their extreme hardness and engineered flexibility allow them to aggressively and effectively scrape off sticky, abrasive material from the belt surface without causing damage.

The Direct and Indirect Impacts on Productivity

The following chart illustrates how this single component creates a cascade of positive effects throughout the mining operation:

Primary Productivity Impacts

TC Scraper Installation

Reduced Carryback

Less Spillage & Mistracking

Cleaner Belt & Rollers

Improved Safety

Less Downtime

for Cleanup & Repairs

Longer Lifespan of

Belt, Idlers, & Pulleys

Reduced Accident Risk &

Lower Labor Costs

Higher System Availability &

Sustained Throughput

1. Maximized Operational Uptime (The Biggest Impact)

- Direct Link: Less carryback means dramatically less spillage. This eliminates the need for frequent production stoppages to clean up tons of accumulated material.

- Productivity Gain: The conveyor system can run for longer, uninterrupted periods. In mining, uptime is directly equivalent to productivity. More tons are moved per shift, directly boosting output.

2. Extended Belt Life

- Direct Link: A clean belt is a healthy belt. Carryback that gets trapped between the belt and pulleys/rollers causes abrasion and damage. Tungsten carbide scrapers prevent this.

- Productivity Gain: Conveyor belts are a massive capital expense. Extending belt life by 20-30% defers replacement costs and avoids the extensive downtime required for a full belt change a process that can halt a section of the mine for days.

3. Reduced Damage to Idlers and Pulleys

- Direct Link: Spillage causes idler rollers to seize and bearings to fail. A clean return strand ensures rollers spin freely as intended.

- Productivity Gain: Reduced frequency of idler replacement lowers maintenance parts costs and labor. It also prevents secondary failures, such as a seized roller gouging the belt, which would lead to even more costly repairs and downtime.

4. Enhanced Safety and Reduced Labor Costs

- Direct Link: By virtually eliminating spillage, tungsten carbide scrapers remove a major slip, trip, and fall hazard. They also minimize the need for personnel to work near dangerous moving equipment to perform cleanup.

- Productivity Gain: Fewer accidents mean no lost time injuries and their associated human and financial costs. It also frees up valuable skilled labor from cleanup duties to focus on more productive tasks like proactive maintenance.

5. Improved System Efficiency

- Direct Link: A clean belt tracks better. A belt suffering from heavy, uneven carryback is prone to mistracking, which can lead to belt edge damage and material spillage.

- Productivity Gain: Consistent, proper belt tracking ensures the system runs smoothly and at its designed capacity, preventing downtime caused by belt alignment issues.

6. Environmental and Housekeeping Benefits

- Direct Link: A cleaner operation means less dust generation from spilled material and a reduced environmental footprint.

- Productivity Gain: While less direct, this contributes to smoother regulatory compliance and a better-organized worksite, which indirectly supports efficient operations.

Cost-Benefit Analysis: A Compelling ROI

The initial investment in a high quality tungsten carbide scraper system is higher than traditional rubber or steel scrapers. However, the return on investment (ROI) is rapid and substantial:

- Cost Savings From:

- Reduced spillage cleanup labor.

- Reduced idler and roller replacement.

- Extended belt life (often the single largest cost saving).

- Reduced energy consumption (a clean, well-aligned belt requires less power to move).

- Revenue Enhancement From:

- Increased material throughput due to higher uptime.

A high-quality conveyor belt scraper is a simple yet highly effective upgrade for any conveyor belt system, especially in facilities that handle bulk materials over long distances. By keeping the belt clean, the scraper prevents material carryback, significantly reducing cleanup time, belt wear, and unplanned downtime. This small investment proves extremely cost effective, delivering fast returns by reducing costs, protecting expensive belt systems, and improving efficiency across material handling operations.

Modern roller conveyors and various types of conveyor systems are the backbone of most assembly lines and distribution centers. When integrated properly, these systems allow even skilled workers to perform tasks more productively because materials flow smoothly and reliably. With less manual intervention needed, companies can focus on cross training employees for higher value work instead of requiring specialized personnel just to manage blockages or spillage.

Ultimately, adding a reliable scraper for conveyor belts directly contributes to the bottom line: lower maintenance costs, longer equipment life, reduced labor hours, and higher throughput, meaning your operation can move materials faster, safer, and more profitably than ever before.

Conclusion

The tungsten carbide scraper is a quintessential example of a “force multiplier” in mining operations. Its impact goes far beyond simple cleaning. By drastically reducing carryback, it directly catalyzes a chain of events that leads to higher uptime, lower operating costs, improved safety, and longer equipment life.

In an industry where every minute of downtime costs thousands of dollars, the implementation of robust, effective belt cleaning solutions like tungsten carbide scrapers is not an optional maintenance activity but a strategic imperative for maximizing conveyor belt mining productivity.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding