At their simplest, these are plates or liners made from tungsten carbide, a super-hard ceramic metal composite (a “cermet”), designed to be welded or bolted onto equipment in high wear areas. They are the “armor” for your most valuable mining machinery.

The term “Advanced Ultra Durable” isn’t just marketing; it signifies key technological improvements over standard hardened steel or basic carbide overlays:

- Superior Hardness: Tungsten carbide particles are significantly harder than quartz, the primary abrasive in most rock and ore.

- Engineered Microstructure: Advanced manufacturing allows for precise control over the carbide particle size, shape, and distribution within the tougher, metallic binder (usually cobalt or nickel).

- Composite Design: They are often part of a composite system a tough, impact resistant steel backing plate with a thick, wear-resistant carbide layer on top.

Why They Are a Game-Changer for Mining Durability

Mining equipment faces a brutal combination of Abrasion, Impact, and Corrosion. Standard materials fail quickly, leading to:

- Frequent downtime for repairs and replacement.

- High maintenance costs (labor and parts).

- Lost production due to halted operations.

- Component failure and potential for secondary damage.

Here’s how advanced carbide wear plates solve these problems:

1. Unmatched Resistance to Abrasive Wear

This is their primary strength. When sharp, hard rock and ore particles slide or impinge against a surface, they gouge out material.

- Mechanism: The ultra-hard tungsten carbide particles resist this gouging and cutting action. Instead of the plate wearing down, the abrasive material itself is worn away.

- Result: Lifespans can be 10 to 25 times longer than 400-500 Brinell hardness (BHN) steel, and significantly longer than chromium carbide overlays.

2. Excellent Impact Resistance (The “Advanced” Part)

Pure hardness can be brittle. Early carbide overlays could crack under heavy impact. Advanced versions solve this by:

- Optimized Carbide/Binder Ratio: Using a higher percentage of the metallic binder in critical areas to absorb impact energy without fracturing.

- Tough Steel Backing: The composite design allows the steel backing to absorb and distribute impact forces, while the carbide surface resists abrasion.

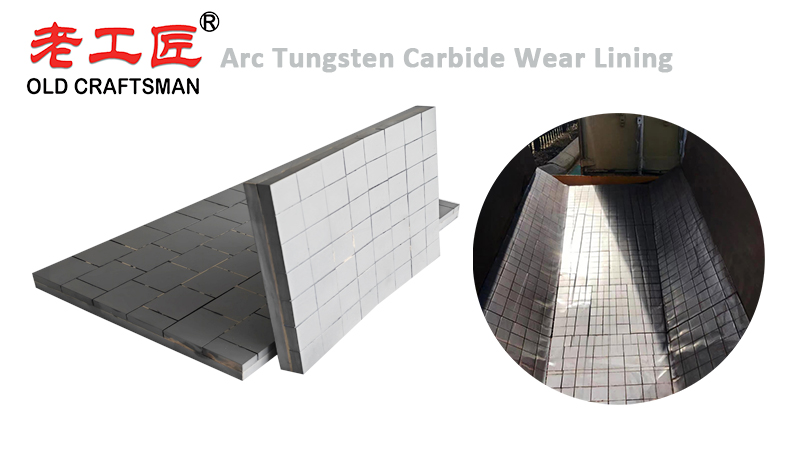

- Segmented Designs: Many plates are made of small, individual carbide tiles embedded in a steel matrix. This allows the plate to flex slightly upon impact, preventing large scale cracking.

3. Enhanced Corrosion & Erosion Resistance

In wet mining environments (slurry pumps, hydro transport), the combination of corrosive water and abrasive particles (erosion corrosion) is devastating.

- Mechanism: The carbide particles and advanced binder alloys (e.g., nickel-based) are highly resistant to chemical attack, maintaining their structural integrity where steel would rapidly corrode and erode.

Key Applications in Mining

You will find these plates protecting the most critical and expensive-to-replace components:

- Haul Truck Beds & Liners: Protecting the body from the constant impact and abrasion of loaded rock.

- Excavator Buckets & Loader Lips: At the point of attack for digging and loading.

- Chutes, Hoppers, and Feeders: Lining surfaces where high velocity, abrasive material changes direction.

- Screw Conveyors & Augers: Protecting the flighting from wear.

- Pump Casings & Impellers: Essential for slurry handling, resisting both abrasion and cavitation.

- Shaker Screen Decks & Liners: Withstanding the constant vibration and abrasion of screening ore.

- Crusher Liners & Hammers: In secondary and tertiary crushing applications.

Types and Selection Criteria

Not all “ultra durable carbide plates” are the same. The “advanced” nature comes from choosing the right type for the job.

| Feature | Description | Best For |

|---|---|---|

| Carbide Particle Size | Fine: Smoother surface, excellent for fine abrasives. Coarse: More resistant to heavy, gouging abrasion. | Slurries, Fine Sands Large, Sharp Rock |

| Binder Composition | Cobalt: Standard, good overall properties. Nickel: Superior corrosion resistance. | General Mining Wet/Salty Environments |

| Form Factor | Continuous Overlay: A solid layer of carbide. Tungsten Carbide Tiles: Individual blocks embedded in steel. | Severe, uniform abrasion. High impact and abrasive conditions. |

| Attachment Method | Weld-On: Permanent, high strength bond. Bolt-On: Allows for easier replacement in the field. | Most applications. Large, complex liners (e.g., truck beds). |

The Economic Justification: Total Cost of Ownership (TCO)

While the upfront cost of advanced carbide plates is significantly higher than steel, the Total Cost of Ownership tells the true story.

Consider this simplified comparison for a haul truck bed liner:

| Factor | AR400 Steel Liner | Advanced Carbide Plate Liner |

|---|---|---|

| Initial Cost | $ (Baseline) | $$$$ (5-8x more) |

| Service Life | 6 Months | 5+ Years (10x longer) |

| Replacements over 5 yrs | 10 | 1 |

| Downtime for Changes | 10 instances | 1-2 instances |

| Labor & Equipment Cost | 10x the cost | 1x the cost |

| Lost Production | Significant | Minimal |

| 5-Year TCO | Very High | Much Lower |

Conclusion: The massive reduction in downtime, maintenance labor, and lost production makes advanced carbide wear plates one of the most cost effective investments a mining operation can make.

Summary

Advanced Ultra Durable Carbide Wear Plates are no longer just a “premium option.” They are a critical engineering solution for maximizing uptime and profitability in the mining industry. Tungsten carbide combines extreme hardness with smart designs that reduce brittleness, offering unmatched protection against abrasion, impact, and corrosion. When chosen correctly for the application, it delivers excellent ROI by significantly lowering the total cost of ownership for mining equipment.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding