In the harsh, abrasive world of mining, equipment longevity and operational efficiency are paramount. For decades, chutes the critical channels that guide bulk materials like ore, coal, and gravel have been protected by materials like AR400 steel, UHMW plastic, or ceramic tiles. While these have their place, tungsten carbide based liners are emerging as the definitive future of wear protection. Here’s why.

1. Unmatched Abrasion Resistance: The Core Advantage

The primary enemy in a mining chute is abrasive wear. When tons of hard, sharp material slide and impact against a surface, it grinds it away like sandpaper.

- The Hardness Factor: Tungsten carbide is one of the hardest materials available for industrial use, second only to diamond. On the Rockwell C (HRC) hardness scale, where standard hardened steel (AR400) sits around 60 HRC, tungsten carbide can reach 70-90 HRC.

- The Result: Carbide liners can last 10 to 25 times longer than traditional steel liners. This dramatic increase in service life is the single most compelling reason for their adoption.

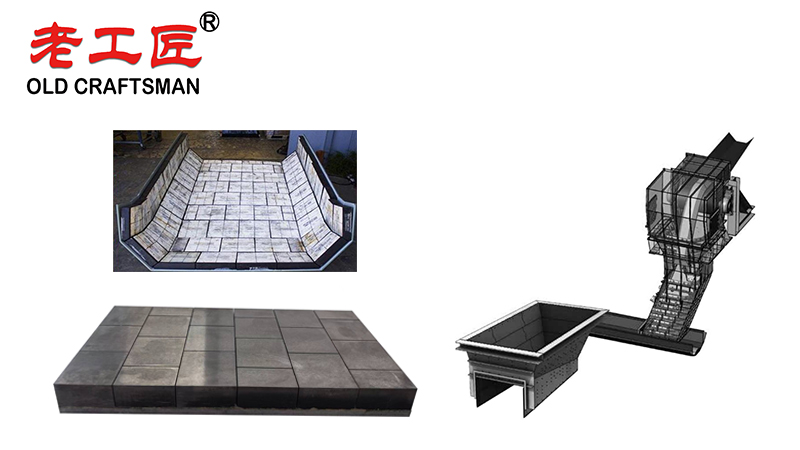

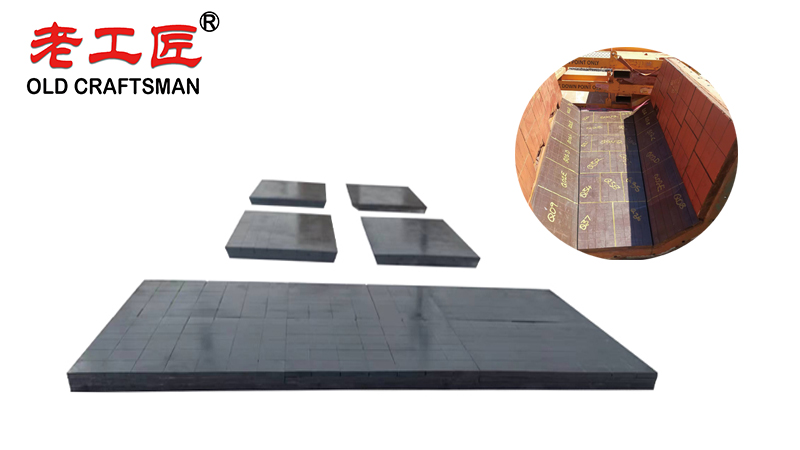

2. The “Self-Relief” Design: Smarter Than a Flat Surface

Many carbide liners are not flat plates. They are often applied as carbide tiles or rods that are embedded into a steel backing plate, creating a patterned surface.

- How it Works: As abrasive material flows over the liner, it contacts the hard, protruding carbide elements. The spaces between the elements allow a protective layer of the material being transported (e.g., ore fines) to build up. This “rock-on-rock” principle means the flowing material grinds against itself, not the steel backing.

- The Benefit: This drastically reduces friction and drag, further enhancing the liner’s life and often improving material flow by reducing build-up and plugging.

3. Significant Reduction in Downtime and Maintenance Costs

In mining, time is money. Unplanned downtime for chute repair is incredibly costly.

- Longer Intervals: Replacing a steel liner every 3-6 months versus a carbide liner every 3-5 years translates to far fewer shutdowns.

- Reduced Labor: Fewer replacements mean less labor spent on the dangerous and physically demanding task of cutting out worn steel and welding in new plates.

- Predictable Maintenance: The long, predictable lifespan of carbide liners allows for planned maintenance during scheduled shutdowns, optimizing entire production schedules.

4. Enhanced Safety and Operational Reliability

A failing chute liner isn’t just an operational headache; it’s a safety hazard.

- Preventing Catastrophic Failure: A worn-through steel liner can lead to material spillage, creating massive cleanup operations, tripping hazards, and even structural damage to underlying equipment.

- Reduced Fire Risk: In certain applications (like coal handling), the sparking caused by metal-on-metal contact from a failed liner can be a fire or explosion hazard. The reliability of carbide mitigates this risk.

- Fewer “At-Risk” Maintenance Tasks: By extending maintenance cycles, the number of times personnel must enter confined spaces or work around heavy machinery is significantly reduced.

5. Improved Flow and Reduced Build-Up

The slick, hard surface of carbide and the self-relief design promote a much smoother flow of material.

- No “Stick-Slip”: Damp, sticky materials are less likely to adhere to the non-stick surface of carbide compared to rusty or pitted steel.

- Reduced Plugging: Consistent flow prevents the blockages and ratholing that plague traditional chutes, leading to a more efficient and continuous operation.

Comparison with Traditional Liner Materials

| Feature | Tungsten Carbide | AR400/500 Steel | Ceramic Tiles | UHMW Plastic |

|---|---|---|---|---|

| Abrasion Resistance | Extremely High (10-25x steel) | Good | High, but brittle | Moderate |

| Impact Resistance | High (with proper backing) | Very High | Low (can shatter) | High |

| Lifespan | Very Long (3-10+ years) | Short (3-12 months) | Moderate | Short-Moderate |

| Weight | Moderate | Heavy | Heavy | Light |

| Installation | Welding/Bolting | Welding | Epoxy/Bolting | Bolting |

| Cost (Initial) | High | Low | Moderate | Low-Moderate |

| Total Cost of Ownership | Lowest | High | Moderate | High |

Addressing the Elephant in the Room: The Initial Cost

Yes, the upfront cost of a carbide chute liner is significantly higher than a steel one. However, the mining industry is shifting its focus from initial purchase price to Total Cost of Ownership (TCO).

When you factor in the dramatically extended service life, massive reductions in downtime, and savings on labor and maintenance, carbide liners almost always prove to be the more economical choice over the lifespan of the equipment.

The Verdict: Why They Are the Future

Carbide chute liners represent a fundamental shift from viewing liners as a consumable item to viewing them as a long term capital investment.

- For New Projects: Engineers are specifying carbide from the design phase to build more reliable, efficient, and “maintenance light” facilities.

- For Existing Operations: Mines are retrofitting problem chutes those with the highest wear rates and most frequent failures with carbide to break the cycle of constant repair.

In conclusion, while traditional materials still have their applications, tungsten carbide chute liners are the future because they directly address the core challenges of modern mining: maximizing uptime, minimizing operating costs, and enhancing safety. Their superior performance and lower total cost of ownership make them not just a premium option, but the most intelligent and economical long-term solution for wear protection.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding