Tungsten carbide belt scraper for conveyors is a wear resistant component used to clean and maintain conveyor belts, typically in heavy duty industrial applications. Here’s a detailed breakdown:

Purpose of the belt scraper:

- Cleaning Belts: Removes sticky or abrasive material (e.g., coal, ore, cement, grain) adhering to conveyor belts.

- Reducing Wear: Prevents carryback (material buildup), which can damage rollers and pulleys.

- Improving Efficiency: Ensures smooth belt operation and reduces downtime.

Why Tungsten Carbide belt scraper?

- Extreme Hardness (HV 1400-1800): Resists abrasion far better than steel or polyurethane.

- Long Service Life: Lasts significantly longer than conventional scrapers, reducing replacement frequency.

- Corrosion Resistance: Suitable for wet or chemically aggressive environments.

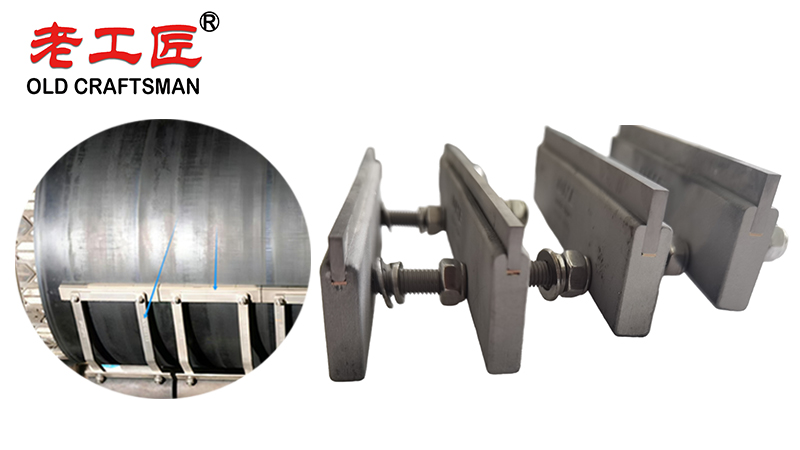

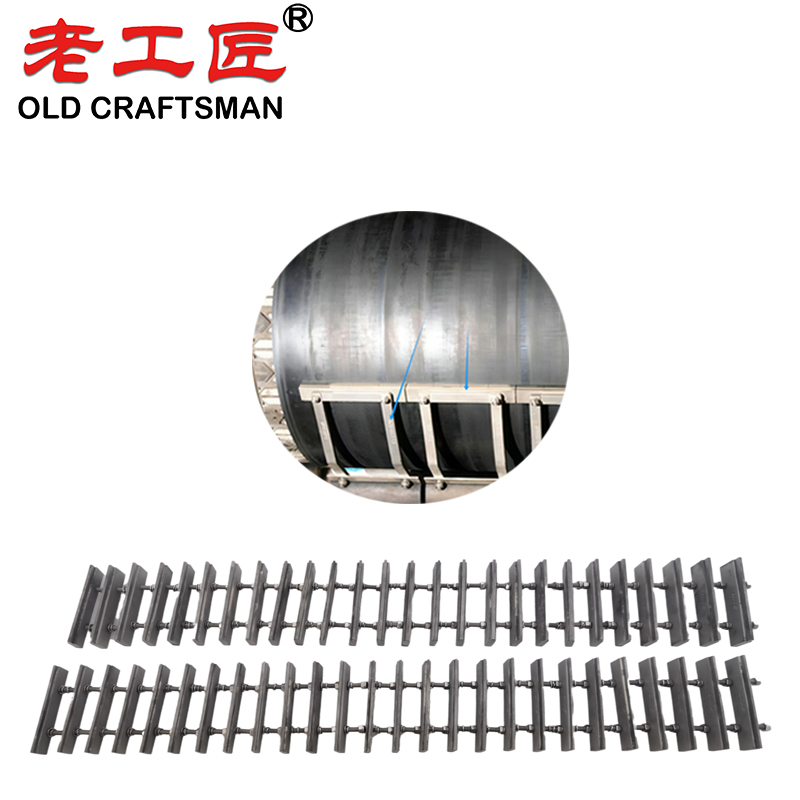

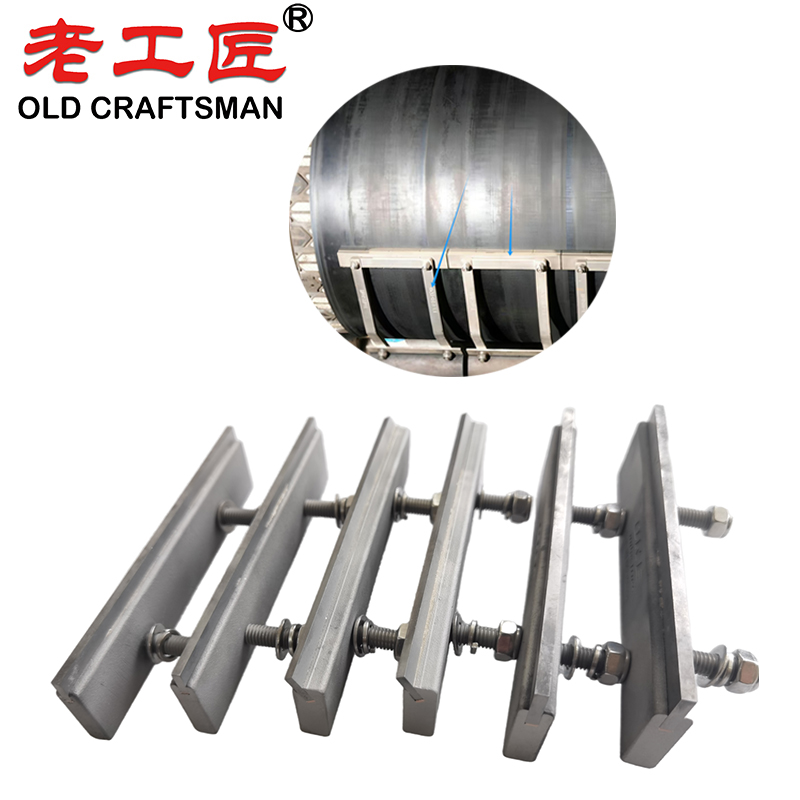

Design Features of our tungsten carbide belt scraper:

- Blade Profile:

- Straight or Curved: Matches belt contour for optimal contact.

- Multi-Segmented: Allows modular replacement of worn sections.

- Mounting System:

- Adjustable tension to maintain consistent pressure on the belt.

- Often paired with a holder (e.g., aluminum or steel frame).

- Surface Treatments:

- Some variants have polished or coated surfaces to reduce belt friction.

Applications of tungsten carbide belt scraper:

- Mining/Quarrying: High abrasion ores, coal.

- Cement/Steel Plants: Clinker, slag, raw materials.

- Power Plants: Ash, biomass handling.

- Food Processing: Sugar, grains (food grade versions available).

Installation Tips of the tungsten carbide belt scraper:

- Angle: Typically 30°–45° to the belt for effective scraping.

- Pressure: Balanced to avoid belt damage while ensuring cleaning.

- Alignment: Parallel to the belt to prevent uneven wear.

Maintenance:

- Inspect regularly for wear or chipping.

- Rotate or replace segments as needed.

- Ensure bolts and mounts remain secure.

Alternatives:

- Polyurethane Scrapers: Softer, less abrasive to belts but wear faster.

- Steel Scrapers: Cheaper but prone to rapid wear in harsh conditions.

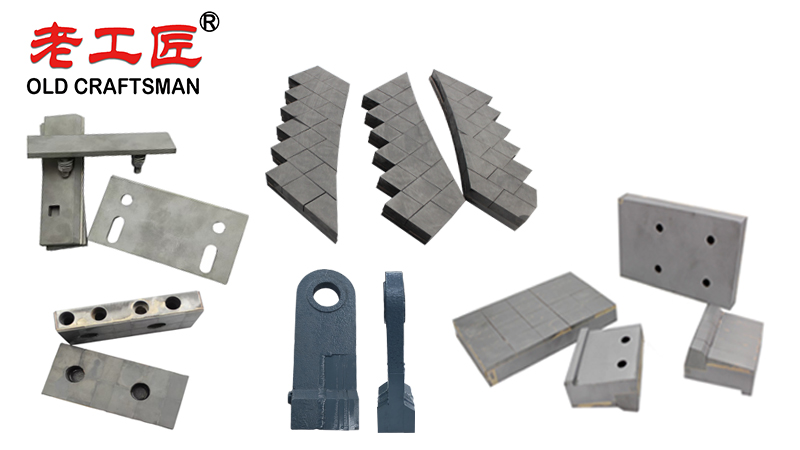

In demanding industrial applications such as mining and cement plants, conveyor belt scraper cutting edges are critical wear parts that directly affect the efficiency and long term operating cost of conveyor systems. To achieve high performing, cost effective solutions under extreme wear and tear and high temperature conditions, leading manufacturers offer a wide range of premium cutting tools made from advanced materials including cemented carbide, tungsten carbide rings, stainless steel, and silicon carbide materials that rank exceptionally high on the Mohs scale of hardness. These bonded abrasives and ultra hard composites ensure superior resistance to abrasion, significantly extending service life while keeping maintenance costs low, making them the preferred choice for heavy duty conveyor belt cleaning systems worldwide.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

We produce carbide vacuum brazed wear parts, like wear liners, hammers and wear spare parts for crushers, mixing blades, conveyor belt scrapers, etc. for mining and crushing. The performance is tens of times longer than the present material, these products can help users save lots of time and money on the shutdown. If you have any wear problems, welcome to contact us for free customized design.

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding