Tungsten carbide (WC) wear plates are widely used in industries where extreme abrasion, erosion, and impact resistance are required. Their exceptional hardness (up to 90 HRA) and wear resistance make them ideal for protecting equipment in harsh environments. Here are some key applications:

1. Mining & Mineral Processing

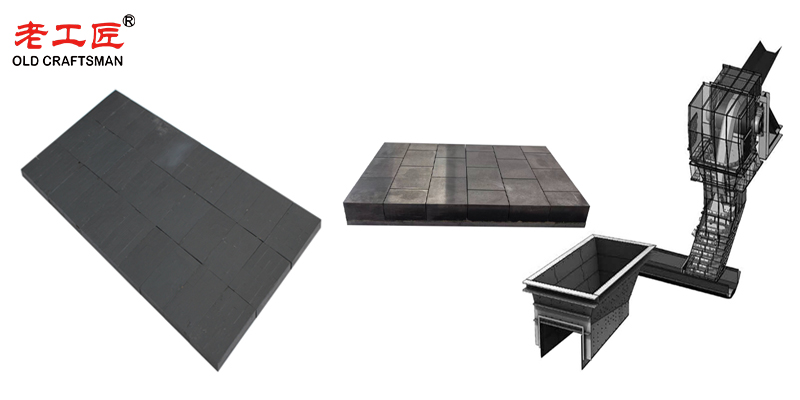

- Chutes, Hoppers, and Conveyors – Protects against abrasive materials like ore, coal, and gravel.

- Screens & Crushers – Extends lifespan by resisting wear from crushing and screening operations.

- Excavator Buckets & Blades – Used in digging and loading abrasive materials.

2. Oil & Gas Industry

- Drilling Equipment – Protects drill pipes, stabilizers, and mud nozzles from erosion.

- Valve Components – Used in choke and control valves to resist sand and slurry erosion.

3. Cement & Power Plants

- Pneumatic Conveying Systems – Shields pipelines handling fly ash, clinker, and cement.

- Fan Blades & Cyclones – Reduces wear from high velocity abrasive particles.

4. Steel & Metal Production

- Blast Furnace Components – Protects against slag and hot abrasive materials.

- Rolling Mills & Guides – Enhances durability in high wear areas.

5. Agriculture & Forestry

- Harvester Blades & Tillage Tools – Improves wear resistance in soil contact applications.

- Wood Chippers – Extends the life of cutting edges.

6. Recycling & Waste Handling

- Shredder Components – Protects against metal, glass, and plastic abrasion.

- Landfill Equipment – Used in bulldozer blades and compactor plates.

7. Construction & Demolition

- Bulldozer Blades & Excavator Teeth – Resists wear from rocks and debris.

- Tunnel Boring Machines (TBMs) – Used in cutter heads for hard rock excavation.

Advantages of Tungsten Carbide Wear Plates:

✔ Superior Hardness – Outlasts steel and ceramic alternatives.

✔ Impact Resistance – Withstands heavy loads without cracking.

✔ Corrosion Resistance – Performs well in wet and chemically aggressive environments.

✔ Customizable – Can be welded, bolted, or bonded to machinery.

Common Forms of Tungsten Carbide Wear Protection:

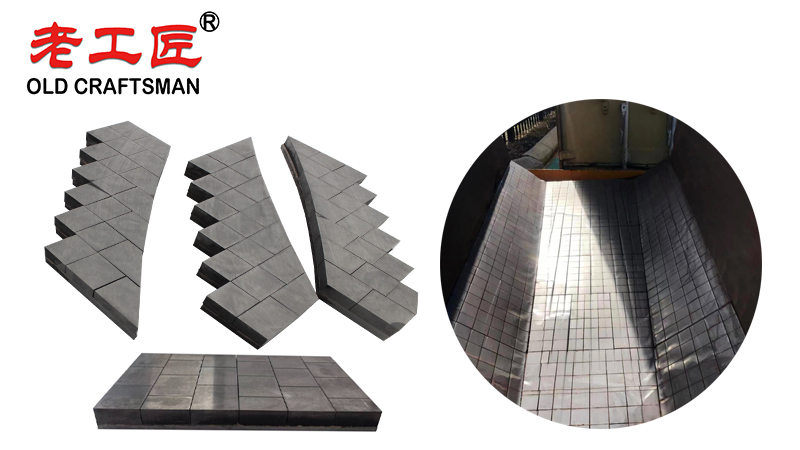

- Overlay Plates (WC particles fused onto steel substrate)

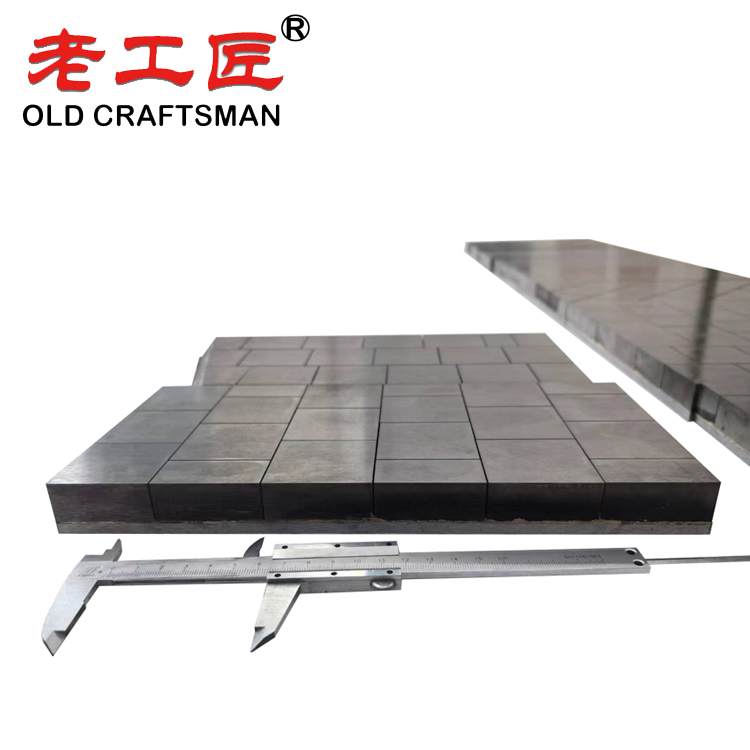

- Solid Carbide Inserts (For extreme wear areas)

- Clad Plates (Bonded layers for high impact zones)

Tungsten carbide wear plates significantly reduce downtime and maintenance costs in heavy industries, making them a cost effective solution for long term wear protection.

In the oil and gas industry, where equipment operates in extremely harsh environments with high temperatures, intense abrasive wear, and often corrosive environments, the material selection for critical wear parts such as landing gear components, pump liners, valves, and chutes is crucial for long term performance and reliability. Mining carbide wear plates are widely recognized as one of the most effective wear-resistant materials due to their exceptional combination of high strength, superior abrasion resistance, and ability to remain highly resistant to both mechanical and environmental factors. These wear plates come in many grades and compositions for different uses. They provide great resistance to gouging, sliding, and impact abrasion, even in extreme conditions. The manufacturing process of tungsten carbide plates typically involves powder metallurgy, hot isostatic pressing (HIP), and precision grinding, resulting in components that significantly extend service life in demanding industrial applications requiring maximum durability and minimal downtime.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding