At its simplest, the choice boils down to a trade-off between ultimate thermal performance and versatility/cost effectiveness.

- Carbide Molds (e.g., Tungsten Carbide): The “Premium Workhorse.” Exceptional thermal conductivity, wear resistance, and longevity. Best for high volume, repetitive processes where thermal management is critical and cost is secondary. Think Die Casting.

- Ceramic Molds: The “Versatile Specialist.” Excellent thermal and chemical stability, high refractoriness, and configurable properties. Best for extreme temperatures, complex geometries, and one-off or short-run products where surface finish and chemical inertness are paramount. Think Investment Casting and Glass Molding.

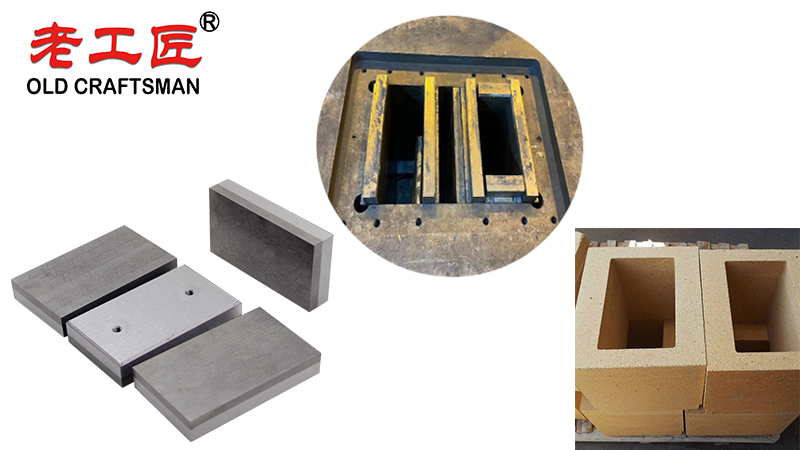

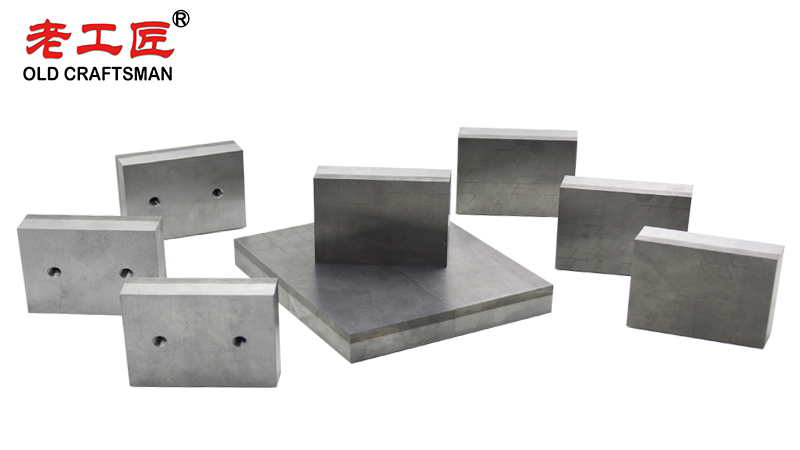

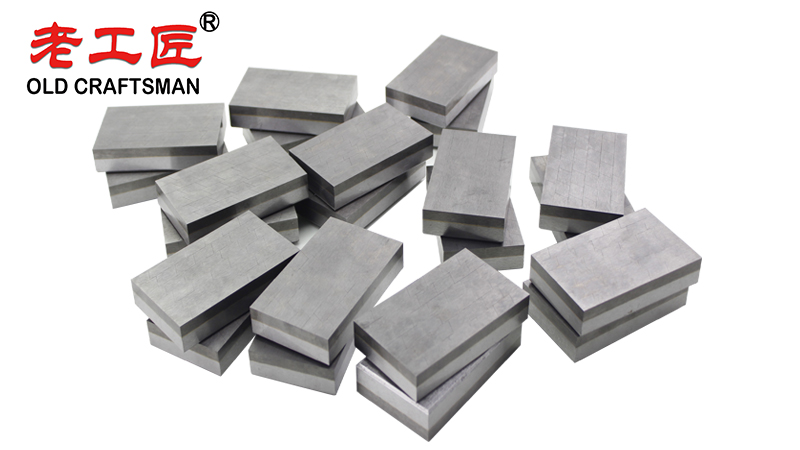

Part 1: Carbide Molds

Carbide molds typically refer to Cemented Carbides or Hard Metals, most commonly Tungsten Carbide (WC) bonded with a cobalt (Co) or nickel (Ni) matrix.

Key Characteristics:

- Extreme Hardness & Wear Resistance: Their primary advantage. They resist erosion from molten metal flow, abrasion, and mechanical fatigue far better than tool steels or most ceramics.

- High Thermal Conductivity: This is a game changer. Carbide molds pull heat away from the casting rapidly, leading to faster solidification and shorter cycle times.

- Good Compressive Strength: They can withstand the immense clamping forces of high pressure die casting machines without deforming.

- High Density & Low Porosity: Results in a very smooth, non-porous mold surface that produces excellent surface finish on the cast part and prevents metal penetration.

- Brittleness: This is their Achilles’ heel. While hard, they are susceptible to thermal shock and can crack if heated or cooled too rapidly or subjected to impact.

Primary Applications:

- Die Casting Dies: Especially for aluminum, zinc, and magnesium. The high thermal conductivity and wear resistance are perfect for millions of cycles.

- Extrusion Dies: For non-ferrous metals and plastics.

- Forging Dies: In certain applications where wear is the primary failure mode.

- Components in High Wear Environments: Core pins, ejector pins, and nozzles where abrasion is a problem.

Part 2: Ceramic Molds

“Ceramic” is a broad term encompassing a wide range of inorganic, non-metallic materials. Their properties vary drastically based on composition (e.g., Alumina, Zirconia, Fused Silica, Silicon Carbide).

Key Characteristics:

- Exceptional Refractoriness: They can withstand significantly higher temperatures than carbides. While carbides may oxidize or soften above 1000°C, advanced ceramics like Zirconia (ZrO₂) can operate above 2000°C.

- Excellent Thermal & Chemical Stability: They are highly inert and resist oxidation and reaction with most molten metals (including superalloys and titanium) and glass.

- Low Thermal Conductivity: This is a double edged sword. It’s excellent for insulating the melt, allowing it to stay fluid to fill thin sections, but it can lead to slower cycle times.

- High Configurability: The composition, grain size, and binder of a ceramic slurry can be engineered to create porous or dense structures, control thermal expansion, and create incredibly complex shapes.

- Inherent Brittleness: Like carbides, they are brittle and have low fracture toughness, making them sensitive to mechanical and thermal shock.

Primary Applications:

- Investment Casting Shells: This is the dominant application. A ceramic slurry and stucco are built up around a wax pattern, which is then melted out, leaving a precise, monolithic ceramic mold for casting superalloys, titanium, and other high performance metals.

- Glass Molding: Pressing glass lenses and components requires extreme surface smoothness and chemical inertness at high temperatures, which ceramics like Silicon Carbide provide.

- Permanent Mold Casting: For ferrous and high temperature non-ferrous metals where steel molds would fail.

- Foundry Cores: Used to create internal cavities in sand castings.

Head-to-Head Comparison Table

| Property | Carbide Molds (Tungsten Carbide) | Ceramic Molds (e.g., Alumina, Zirconia) | Winner & Rationale |

|---|---|---|---|

| Hardness & Wear | Extremely High | High to Very High | Carbide. Unmatched abrasion resistance for high volume production. |

| Fracture Toughness | Low | Very Low | Carbide. Still brittle, but generally tougher than most ceramics. |

| Thermal Conductivity | Very High | Very Low | Carbide. For rapid heat extraction. Ceramic wins for insulation. |

| Maximum Service Temp. | ~1000°C (can oxidize) | >1500°C – 2000°C+ | Ceramic. The clear choice for ultra-high-temperature processes. |

| Thermal Shock Resistance | Poor | Fair to Good (depends on type) | Ceramic (typically). Fused Silica, for example, has a very low CTE, making it excellent. |

| Chemical Inertness | Good, but can react | Excellent | Ceramic. Inert to virtually all molten metals and slags. |

| Formability / Complexity | Low (Machined from solid) | Very High | Ceramic. Can be cast or built into intricate, near-net shapes. |

| Initial Cost | Very High | Low to Moderate | Ceramic. Machining a solid block of carbide is extremely expensive. |

| Lifecycle Cost | Can be lower for high volume | Lower for prototypes/short runs | Tie. Depends entirely on the application volume and process. |

| Primary Application | Die Casting Dies | Investment Casting Shells | Tie. Each dominates its respective field. |

The Deeper Dive: Selecting the Right Refractory

The choice isn’t just about material properties; it’s about the entire manufacturing process.

When to Choose CARBIDE:

- Volume and Speed: You are running a high volume die casting operation (e.g., automotive parts). The high initial cost is justified by the mold’s long life and the productivity gains from fast cycle times.

- Precision and Finish: You require a mirror-like surface finish and dimensional stability over hundreds of thousands of cycles.

- Abrasion is the Enemy: The primary failure mode of your current tooling is wear or erosion, not thermal cracking.

When to Choose CERAMIC:

- Extreme Temperature: You are casting metals with very high melting points (e.g., titanium, cobalt, or nickel-based superalloys). No carbide can survive this environment.

- Complex Geometry: The part has intricate details, undercuts, or internal passages that are impossible to machine into a solid block. The investment casting process is ideal here.

- Chemical Purity is Critical: The molten material is highly reactive, and any contamination from the mold would ruin the product (e.g., in semiconductor or aerospace applications).

- Prototyping or Short Runs: The lower initial cost and the ability to create a mold without expensive machining make ceramics the economical choice.

Hybrid and Niche Solutions

The line isn’t always black and white. Advanced applications often use hybrid approaches:

- Ceramic Cores in Carbide Dies: A complex internal passage is formed by a precision ceramic core placed inside a carbide die for die casting.

- Ceramic Coatings: Tool steel or carbide molds can be coated with a thin layer of ceramic (e.g., via Thermal Spray) to enhance wear and corrosion resistance, combining the toughness of the substrate with the surface properties of the ceramic.

- Silicon Carbide (SiC): This material blurs the line! It’s a ceramic but has thermal conductivity rivaling some metals. It’s expensive but is used in high performance applications like brake discs, foundry furniture, and premium glass molds.

Conclusion

There is no universal “best” material. The selection between carbide and ceramic molds is a fundamental engineering decision based on the process requirements.

- For the brutal, high volume, repetitive world of die casting non-ferrous metals, Carbide is the undisputed champion of durability and productivity.

- For the demanding, high temperature, geometrically complex world of investment casting superalloys or glass molding, Ceramic molds offer the necessary refractoriness, stability, and formability.

Investment casting, also known as lost wax casting, is a highly versatile and cost effective precision casting method widely used for manufacturing complex, high performance components such as turbine blades. This process excels at producing parts with exceptional dimensional accuracy, high strength, and superior surface finish from difficult-to-machine materials, including high temperature refractory alloys, carbide, stainless steel, and other thermally conductive metals.

Unlike permanent mold casting processes, investment casting uses expendable wax patterns coated with refractory molds that can withstand extreme temperatures, enabling the production of intricate geometries that would be impossible or prohibitively expensive with traditional machining. The resulting components offer high quality and high precision while maintaining tight tolerances, making the process ideal for cutting tools, aerospace turbine blades, medical implants, and other demanding applications requiring a wide range of high-performance materials.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding