Choosing the right tungsten carbide (TC) blade for an industrial intensive mixer depends on several factors, including the material being processed, mixer design, operating conditions, and wear resistance requirements. Here’s a structured guide to help you select the best blade:

1. Material Being Processed

- Abrasive Materials (e.g., ceramics, minerals, hard plastics):

- Use high grade tungsten carbide (WC-Co) with high cobalt (8-12%) for better toughness.

- Consider ultra-fine grain carbide for enhanced wear resistance.

- Corrosive or Chemical-Laden Mixes (e.g., pharmaceuticals, food, chemicals):

- Opt for corrosion-resistant carbide grades or coatings (e.g., TiAlN or DLC coatings).

- High Impact Mixing (e.g., rubber, composites, metals):

- Choose tungsten carbide with a tough binder (e.g., 6-10% cobalt) to prevent chipping.

2. Blade Design & Geometry

- Straight vs. Curved Blades:

- Straight blades are better for shear-intensive mixing.

- Curved/helical blades improve material flow and reduce power consumption.

- Edge Sharpness & Angle:

- Sharp edges (20°-30°) for fine dispersion (e.g., paints, inks).

- Blunt/rounded edges for high impact mixing (e.g., rubber, metals).

3. Wear Resistance & Longevity

- Coated vs. Uncoated Carbide:

- TiN/TiCN coatings improve lifespan in abrasive environments.

- Uncoated carbide is cost effective for moderate wear applications.

- Grain Size of Tungsten Carbide:

- Sub-micron (0.5-1µm) grains for extreme wear resistance.

- Coarser grains (2-5µm) for better impact resistance.

4. Mixer Operating Conditions

- High Speed Mixers (>500 RPM):

- Require balanced, high density carbide to avoid vibration and cracking.

- High Temperature Mixing:

- Use heat resistant grades (e.g., WC-CoCr) to prevent thermal cracking.

5. Manufacturer & Customization

- Reputable Suppliers:

- Kennametal, Sandvik, Mitsubishi Materials, Zhuzhou Cemented Carbide.

- Custom Blades:

- Some mixers need bespoke blade shapes (e.g., asymmetrical, reinforced tips).

6. Cost vs. Performance Trade-Off

- Premium Grades (e.g., Kennametal K68, Sandvik H10F):

- Best for 24/7 operations, but higher upfront cost.

- Economy Grades (e.g., Chinese YG6, YG8):

- Suitable for low-to-medium duty cycles.

Final Recommendation

For heavy-duty industrial mixing (e.g., ceramics, minerals, rubber):

✅ Grade: WC-10%Co (e.g., Kennametal K10)

✅ Coating: TiAlN (if corrosive/abrasive)

✅ Geometry: Curved with reinforced edges

✅ Grain Size: Sub-micron (0.8µm)

For food/pharmaceutical mixing:

✅ Grade: Corrosion resistant WC-CoCr

✅ Coating: Polished or DLC-coated for hygiene

✅ Geometry: Smooth, easy-to-clean design

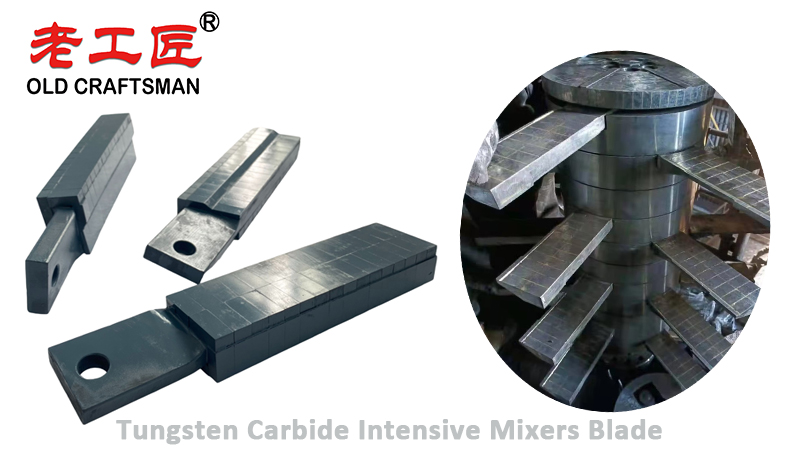

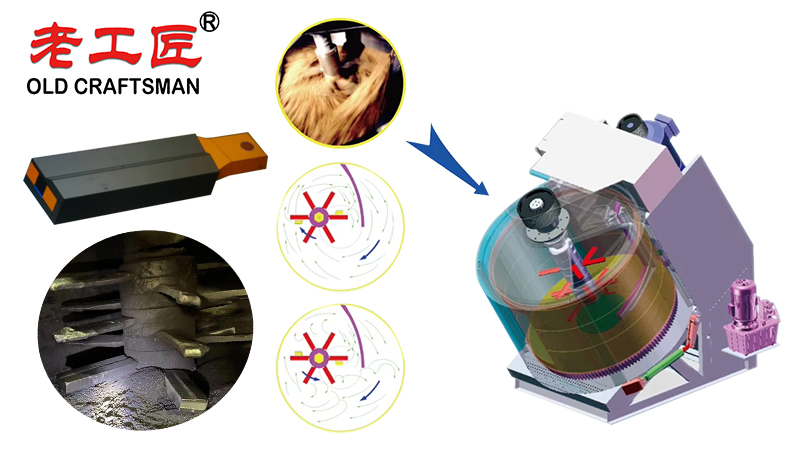

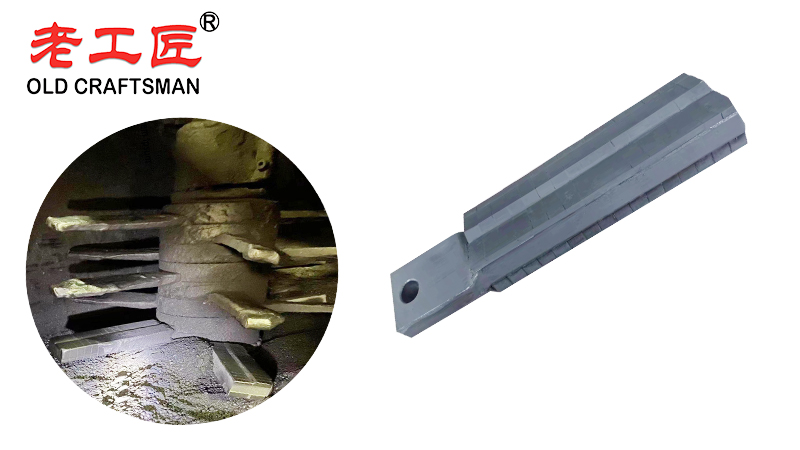

In the manufacturing process of carbide intensive mixers, the blade cutting edge is typically made from premium cemented carbide (tungsten carbide) to ensure exceptional high strength, outstanding abrasion resistance, and superior performance under abrasive wear conditions. Compared to traditional carbon steel or even standard stainless steels, cemented carbide wear parts deliver significantly longer service life in high temperature environments, making them far more heat resistant and corrosion resistant when processing highly abrasive materials. This combination of mechanical properties ensures reliable, high performance operation while remaining a cost effective solution across a wide range of demanding industrial applications. For less extreme conditions, high quality stainless steel or specially treated steels can still resist material wear effectively, but for maximum durability and efficiency, cemented carbide remains the cutting tool material of choice.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding