There is no single “best” carbide tip. The best tip is the one that provides the lowest cost-per-ton for your specific application, balancing wear life and crushing performance.

Step 1: Understand the Two Key Components of a Carbide Tip

A carbide tip is not pure tungsten carbide. It’s a composite material:

- Tungsten Carbide (WC): The hard, wear resistant particles. Higher WC content generally means better wear life.

- Cobalt (Co) Binder: The metallic “glue” that holds the carbide particles together. A higher cobalt content makes the tip tougher and more shock resistant but slightly less wear resistant.

The ratio and quality of these components, along with the manufacturing process (e.g., sintering), define the tip’s properties.

Step 2: Analyze Your Crushing Application

This is the most important step. You must match the tip’s properties to the material you are crushing.

| Application Factor | What to Look For | Recommended Carbide Grade / Characteristic |

|---|---|---|

| Material Type & Abrasiveness | High Abrasion, Low Impact: • Sandstone • Granite • Gravel • Recycled Asphalt (without steel) | High Wear Resistance: • Fine-to-medium grain carbide. • Lower cobalt content (6-8%). • Focus on maximizing life. |

| High Impact & Abrasion: • Basalt • Dolerite • Taconite • Recycled Concrete with rebar | High Toughness: • Medium-to-coarse grain carbide. • Higher cobalt content (9-12%). • Prioritizes shock resistance over pure wear life. | |

| Feed Size & Throughput | Large Feed Size & High Tonnage: Creates more impact stress on the tips. | High Toughness: A tougher grade is essential to prevent chipping and catastrophic failure. |

| Desired Product Shape | Producing Cubical Aggregates or Manufactured Sand: Requires a well-formed tip to maintain the rock-on-rock “anvil” action in the crushing chamber. | Balanced Grade & Good Geometry: The tip must maintain its shape as long as possible. A balanced grade (e.g., 10% Co) is often ideal. |

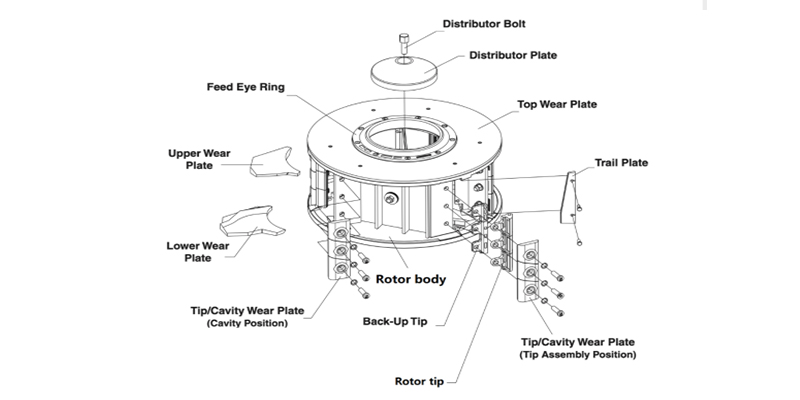

| Rotor Speed & Crusher Model | High Rotor Speed: Increases impact energy, demanding higher toughness. Different crusher models (e.g., Metso Barmac, Sandvik, Terex Canica) have specific tip designs and mounting systems. | Check OEM Specifications: Ensure the tip geometry and locking mechanism are correct. High speed rotors may need a tougher grade. |

Step 3: Choose the Right Carbide Grade

Carbide grades are typically categorized by their intended use. Reputable suppliers will provide this classification.

| Carbide Grade Type | Cobalt Content | Grain Size | Best For | Compromise |

|---|---|---|---|---|

| Wear-Resistant | Low (6-9%) | Fine | Highly abrasive, non-explosive rock. Maximizing tip life in “easy” conditions. | Lower impact resistance. Prone to chipping. |

| Balanced / General Purpose | Medium (9-11%) | Medium | The most common choice. Handles a mix of abrasion and impact (e.g., basalt, granite). | The “jack-of-all-trades.” Excellent balance for most mining apps. |

| High-Impact / Tough | High (12-15%) | Coarse | Very hard, explosive rock or large feed with tramp metal. High impact recycling. | Lower wear resistance. Will wear faster in purely abrasive conditions. |

Key Takeaway: For most hard rock mining applications (basalt, granite, etc.), a Balanced or High Impact Grade is the safe and most cost effective choice.

Step 4: Evaluate Tip Design and Quality

Not all tips of the same grade are created equal.

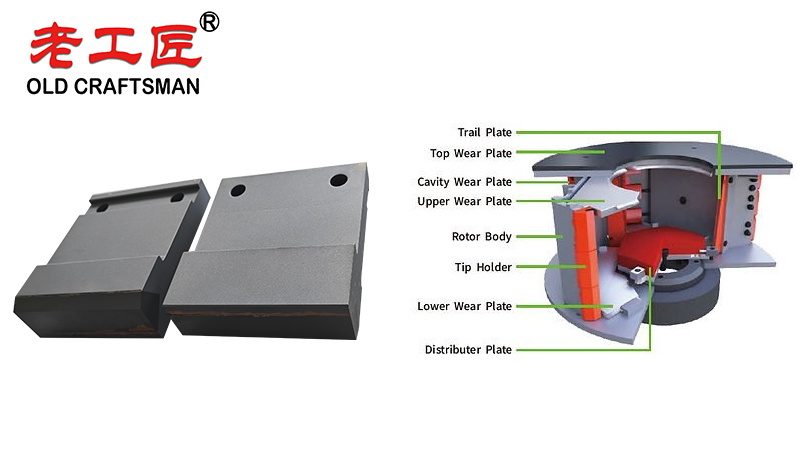

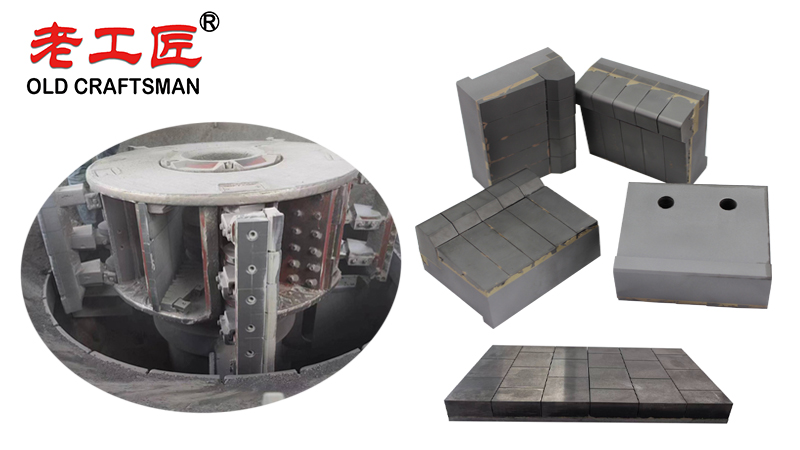

- Geometry & Fit: The tip must fit the rotor perfectly. Poor fit leads to movement, uneven wear, and premature failure. Always use the correct design for your crusher model.

- Carbide Quality: The quality of the raw tungsten carbide powder and the sintering process matters. Reputable brands have consistent, high-quality control.

- The “Brazing” Debate:

- Brazed Tips: The carbide tip is brazed onto a steel holder. This is the traditional method.

- Pros: Lower initial cost.

- Cons: The braze joint is a potential failure point. If the tip breaks, the entire assembly is often lost. Requires skilled labor for replacement.

- Cartridge Tips / Locking Tip Systems: The carbide tip is a self-contained cartridge that locks mechanically into the rotor.

- Pros: Faster, easier, and safer replacement. No burning or risk of damaging the carbide with heat. The steel holder is protected and reused.

- Cons: Higher initial cost per tip.

- Recommendation: For mining applications, cartridge systems are almost always superior due to reduced downtime and safer maintenance.

- Brazed Tips: The carbide tip is brazed onto a steel holder. This is the traditional method.

Step 5: Partner with a Reputable Supplier

Your supplier is a key partner in this process.

- OEM (Original Equipment Manufacturer): e.g., Metso, Sandvik. They offer guaranteed compatibility and performance but often at a premium price.

- Quality Aftermarket Suppliers: Many specialized foundries produce excellent aftermarket tips that can meet or exceed OEM performance at a lower cost.

- Look for suppliers who are willing to discuss your application and recommend a specific grade.

- Ask for testimonials or case studies from similar applications.

- Inquire about their quality control processes and warranties.

Final Recommendation

For a typical VSI in a hard rock mining application:

- Start with a Balanced Grade carbide tip (e.g., ~10% Cobalt).

- Strongly consider a cartridge-style tip system for operational efficiency.

- Work with a knowledgeable supplier and be prepared to provide details about your operation.

The cheapest tip per piece is rarely the cheapest per ton crushed. Investing time in selecting the right rotor tip will pay significant dividends in reduced downtime, lower maintenance costs, and higher quality final product.

VSI carbide rotor tips are manufactured using high performance carbide powders, primarily tungsten carbide (WC) and pure tungsten-based cemented carbide, selected for their exceptional combination of properties. These premium grade powders, with precisely controlled particle size, ensure superior mechanical properties, including outstanding tensile strength, high impact resistance, and excellent abrasion resistance. Thanks to tungsten carbide’s extremely high melting point and inherent corrosion resistant nature, the resulting wear resistant materials demonstrate exceptional high resistance to both abrasive wear and chemical attack, giving them the ability to withstand the most demanding wear applications. Advanced manufacturing processes further optimize density and microstructure, making these cemented carbide components the preferred choice for high temperature cutting tools and heavy duty impact environments where long service life and reliability are critical.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding