High Pressure Grinding Rolls (HPGRs) are critical in mineral processing, and selecting the proper tungsten carbide wear plates is essential for optimal performance and longevity. Here’s a guide to help you choose the right wear plates:

Key Selection Factors

- Material Composition

- Look for high grade tungsten carbide with optimal cobalt binder content (typically 6-12%)

- Consider specialized formulations for extreme abrasion or impact conditions

- Hardness vs. Toughness Balance

- Higher hardness (up to 1500 HV) for maximum wear resistance

- Higher cobalt content for better impact resistance in more demanding applications

- Grain Size

- Fine grain sizes (1-3 μm) for superior wear resistance

- Medium grain sizes for applications requiring both wear resistance and toughness

- Plate Geometry

- Match the plate size and thickness to your specific HPGR model

- Consider interlocking designs for better stability

Application-Specific Considerations

- Ore Characteristics: Harder ores require more wear resistant grades

- Operating Pressure: Higher pressures may require tougher formulations

- Throughput Rates: Higher volumes may justify premium wear plates

Leading Manufacturers

Consider reputable suppliers like:

- Zhuzhou Old Craftsman Precision Alloy Co.,Ltd.

Maintenance Tips

- Regular inspection for cracks or excessive wear

- Proper installation to avoid stress concentrations

- Monitor performance to determine optimal replacement intervals

A successful tungsten carbide HPGR wear plate solution balances material science, engineering design, and operational practicality. Prioritize high impact zones with tunsgten carbide, optimize installation for quick maintenance, and partner with experienced suppliers to ensure longevity in harsh mining environments.

Zhuzhou Old Craftsman Precision Alloy Co.,Ltd. a professional Chinese manufacturer of tungsten carbide products. Our main products are tungsten carbide blanks, precision products and brazing mining wear products.

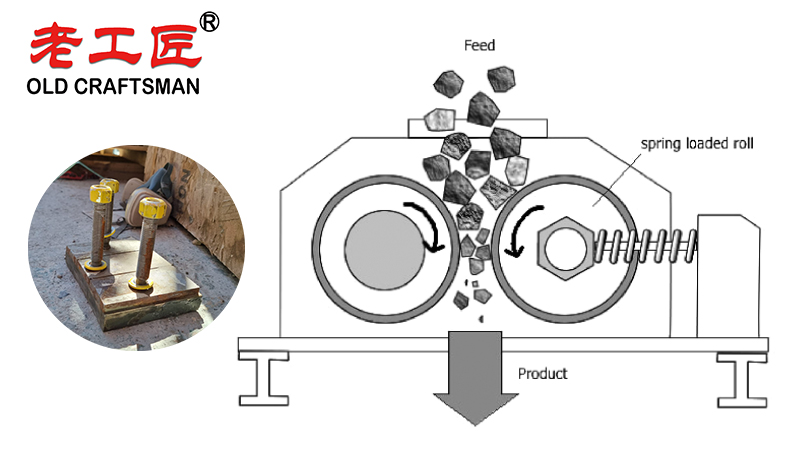

In the demanding field of mechanical engineering, High Pressure Grinding Rolls (HPGR) flanges and associated heavy duty wear parts are manufactured using advanced wear resistant materials that offer exceptional abrasion resistance, high strength, and superior mechanical properties even under extreme high temperature conditions. These wear plates, studded surfaces, and customized wear protection components are available in a wide range of shapes and sizes to suit specific applications. The advanced manufacturing processes and specially developed resistant materials with low coefficient of friction, the service life of HPGR components, cutting tools, and other abrasive wear exposed parts is significantly extended, delivering reliable, long lasting wear solutions even in the harshest, most abrasive environments (from mining to cement and beyond), while dessert plates remain blissfully unaffected by such industrial concerns.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding