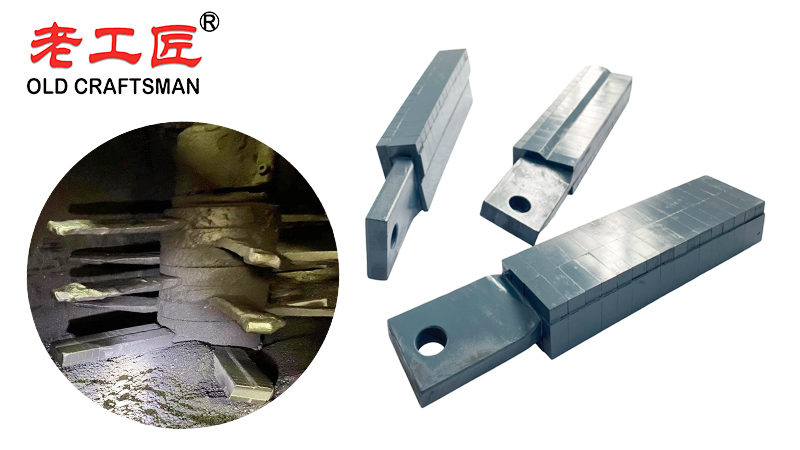

Concrete mixer carbide blades offer several advantages over traditional steel or iron paddles due to the superior properties of tungsten carbide. Here are the key benefits:

1. Extreme Wear Resistance

- Carbide is much harder than steel (up to 3-4 times more wear resistant), making it ideal for abrasive concrete mixes.

- Significantly extends paddle lifespan, reducing replacement frequency.

2. Reduced Downtime & Maintenance Costs

- Longer service life means fewer replacements, lowering labor and part costs.

- Ideal for high volume mixing operations (e.g., ready mix plants, precast factories).

3. Improved Mixing Efficiency

- Maintains sharp edges longer, ensuring consistent mixing performance.

- Prevents material buildup (less “concrete sticking”), leading to better homogeneity.

4. Corrosion Resistance

- Tungsten carbide resists chemical corrosion from cement alkalinity and additives, unlike standard steel.

5. Cost-Effective in the Long Run

- Higher upfront cost but lower total cost per hour due to extended durability.

6. Suitable for Harsh Mixes

- Performs well with abrasive aggregates (e.g., granite, gravel) and fiber reinforced or high strength concrete.

Applications:

- Drum mixers (stationary or mobile)

- Twin shaft mixers

- Pan mixers

- High intensity mixing systems

In intensive mixers, blades face heavy wear from friction and contact with materials. This often creates high temperatures that can damage standard materials. For high performance applications requiring superior mechanical properties, such as elevated tensile strength and resistance to abrasive wear at elevated temperatures, tungsten carbide intensive designs stand out among wear resistant materials. These carbide based blades stay hard and strong in many conditions. They are stronger and resist wear better than options like 316 stainless steel. While 316 provides excellent corrosion resistance, it lacks the hardness achievable through precipitation hardenable stainless steels or carbide reinforcements, which can be further enhanced via heat treatment. The production process for high performance blades usually involves sintering or cladding techniques. These methods have higher initial costs. However, they offer long term durability. This reduces overall expenses by extending service life and minimizing downtime.

Comparison vs. Steel Paddles:

| Feature | Carbide Paddle | Steel Paddle |

|---|---|---|

| Wear Resistance | ⭐⭐⭐⭐⭐ | ⭐⭐ |

| Lifespan | 5-10x longer | Standard |

| Corrosion Resistance | High | Moderate |

| Initial Cost | Higher | Lower |

| Long-Term ROI | Better | Lower |

High-performance cemented carbide cutting tools, such as those used in intensive mixers, feature blades and wear parts made from tungsten carbide or high trength stainless steel. These wear resistant materials are specifically engineered to resist material abrasion and maintain excellent mechanical properties even under high temperatures. By using tungsten carbide rings and other strong parts, manufacturers can greatly reduce wear on important components. This leads to lower costs from needing fewer replacements. While the initial fixed costs and total fixed cost for such premium tools may be higher, the overall production costs decrease over time due to extended service life and reduced downtime, making them a cost effective choice for demanding industrial applications.

Conclusion:

Carbide paddles are ideal for heavy uty concrete mixing where abrasion resistance and longevity are critical. While they cost more upfront, they save money over time by reducing downtime and replacement frequency.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

We produce carbide vacuum brazed wear parts, like wear liners, hammers and wear spare parts for crushers, mixing blades, conveyor belt scrapers, etc. for mining and crushing. The performance is tens of times longer than the present material, these products can help users save lots of time and money on the shutdown. If you have any wear problems, welcome to contact us for free customized design.

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding