Product Overview

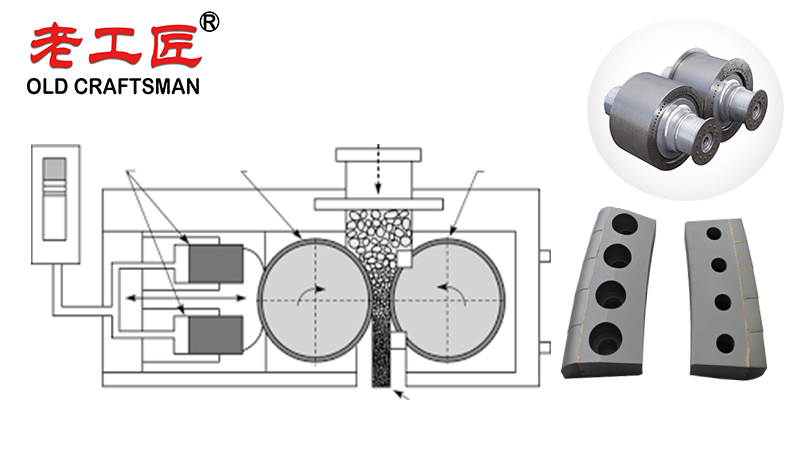

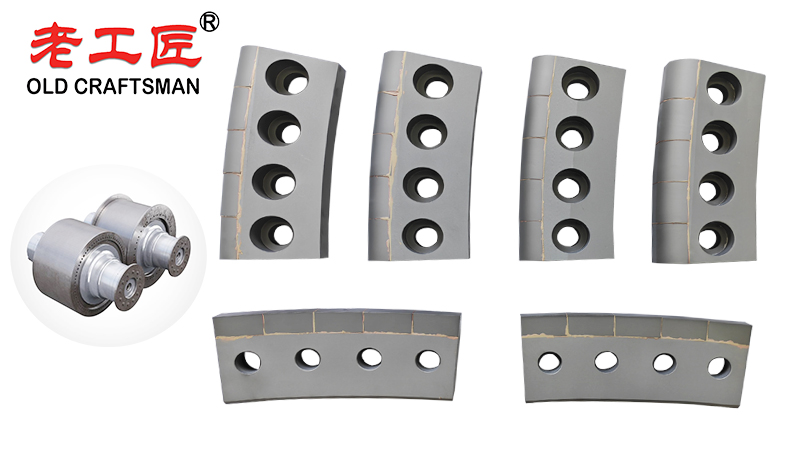

High Pressure Grinding Roller (HPGR) tungsten carbide edge blocks are critical wear parts used in mineral processing and mining operations. These customizable blocks provide superior wear resistance for crushing and grinding applications.

Key Features

- Material: Premium tungsten carbide (WC-Co) composition

- Customization Options:

- Various sizes and geometries to fit different HPGR models

- Multiple carbide grades available (YG8, YG11, YG15, etc.)

- Custom edge designs (square, chamfered, radiused)

- Special surface treatments available

- Brand-specific configurations (ZZ OLD CRAFTSMAN etc.)

- Performance Benefits:

- Exceptional wear resistance (3-5x longer life than standard alloys)

- High compressive strength

- Excellent impact resistance

- Maintains sharp edges longer

- Reduced downtime for replacements

Applications

- Ore crushing and grinding operations

- Cement production

- Diamond processing

- Industrial minerals processing

Ordering Information

Available as individual replacement blocks or complete edge assemblies. Custom designs require specifications including:

- HPGR model/make

- Current block dimensions

- Operating conditions (pressure, material processed)

- Required carbide grade

- Quantity needed

Technical Support

Our engineering team can assist with:

- Wear pattern analysis

- Performance optimization

- Custom design solutions

- Installation guidance

The consistent grinding gaps maintained by tungsten carbide edge blocks ensure uniform pressure distribution, resulting in higher throughput and more efficient crushing. This leads to better particle size distribution, which enhances downstream processes like flotation and leaching, ultimately improving overall productivity.

In summary, tungsten carbide edge blocks improve HPGR operations in mining by offering unmatched wear resistance, improved efficiency, and significant cost savings. Their ability to withstand extreme conditions and maintain consistent performance makes them a critical advancement in mineral processing technology.

The edge block in High Pressure Grinding Rolls (HPGR) is a critical wear component that operates under extreme conditions of high temperatures, ultra high pressure, high impact, and severe abrasion. To ensure long service life and high performance across a wide range of challenging ore types and particle size distributions, the edge block must be manufactured from advanced wear resistant tungsten carbide materials with exceptional mechanical properties, outstanding abrasion resistance, and superior resistance to high impact abrasive wear.

Key material requirements include high strength at the cutting edge, excellent surface roughness control after grinding, and proven low wear rates even when processing highly abrasive feeds. Rigorous testing methods including laboratory scale stainless steel wheel abrasion tests, pilot-scale HPGR campaigns, and full scale field trials are used to quantify the ability of a material to withstand these punishing conditions and deliver significantly extended service life compared to conventional solutions.

By combining optimized metallurgy with innovative design, modern HPGR edge blocks achieve breakthrough high wear performance, reducing downtime, lowering maintenance costs, and maximizing throughput in the most demanding mineral processing applications worldwide.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding