The High Pressure Grinding Rolls (HPGR) has become a cornerstone of modern, energy efficient comminution circuits in the mining industry. Its ability to induce micro-cracks in ore particles through inter-particle compression leads to significant energy savings and improved downstream liberation. However, the productivity and operating cost of an HPGR are critically dependent on the wear life of its key components: the rolls and the tungsten carbide cheek plates.

While much attention is given to the roll wear surface, the cheek plates play an equally vital role. They contain the feed material at the ends of the rolls, ensuring a consistent pressure zone and preventing sideward leakage. The adoption of High Performance Carbide Cheek Plates represents a transformative advancement, directly addressing the primary challenges of wear and downtime to unlock new levels of productivity.

The Challenge: Traditional Cheek Plate Limitations

Traditional cheek plates are often made from martensitic white cast iron or through hardened steels. While hard, these materials are no match for the highly abrasive nature of modern ores. This leads to several critical issues:

- Rapid Wear: The constant sliding abrasion from the ore stream quickly wears down traditional plates, creating gaps.

- Loss of Particle Bed Confinement: As the plates wear, the “seal” they form with the rolls is compromised. This allows fine material to bypass the grinding zone, reducing throughput and efficiency.

- Reduced Product Quality: Leakage leads to a higher proportion of un-pressed or poorly pressed material in the product, diminishing the benefits of micro-cracking and increasing the workload for downstream processes like ball mills.

- High Maintenance Frequency & Cost: Frequent replacement of cheek plates results in significant downtime, labor costs, and inventory expenses.

The Solution: High Performance Carbide Cheek Plates

Carbide, specifically tungsten carbide (WC-Co), is a composite material known for its exceptional hardness and wear resistance. High-performance carbide cheek plates are engineered to leverage these properties, typically through one of two methods:

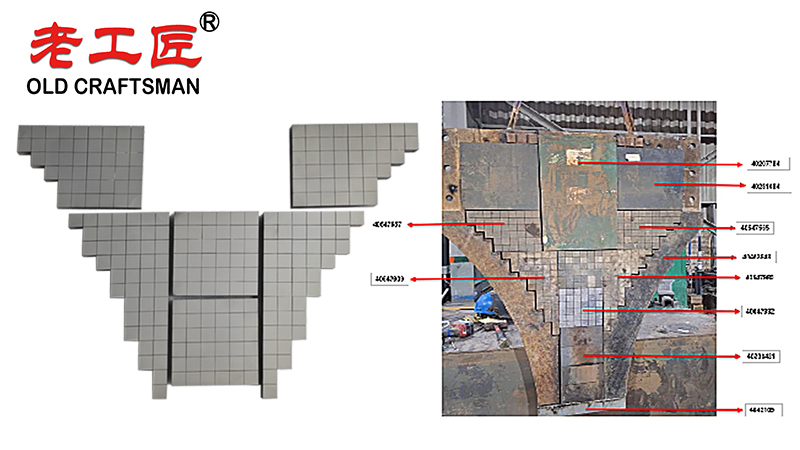

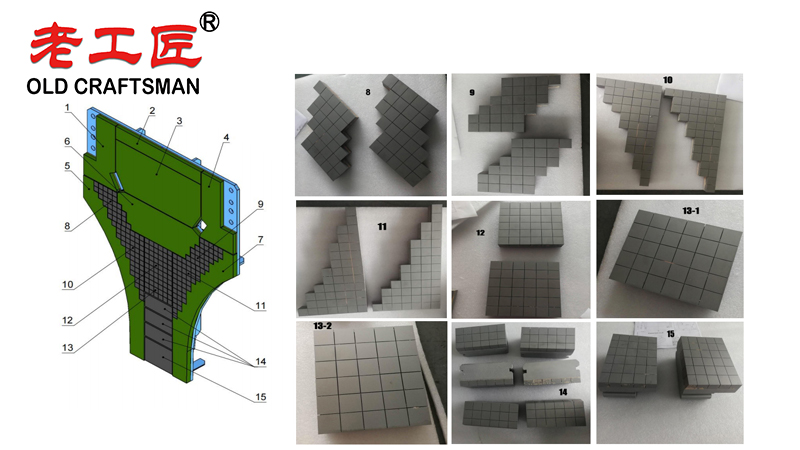

- Solid Carbide Inserts: Large, custom-shaped blocks of carbide are mounted into a robust steel holder.

- Carbide-Hardfaced / Clad Plates: A thick layer of wear resistant carbide is welded or fused onto a structural steel base plate.

Key Mechanisms for Productivity Enhancement

1. Dramatically Extended Service Life

- Mechanism: Carbide’s hardness (often 1300-1600 HV) is vastly superior to that of cast iron (~600-800 HV). This provides an order-of-magnitude improvement in resistance to abrasive wear.

- Productivity Impact:

- Reduced Replacement Frequency: Wear resistance, wear life increases of 3x to 10x are common compared to traditional materials.

- Maximized Uptime: Fewer stoppages for plate changes directly increase annual operating hours and throughput during mineral processing.

2. Maintained Optimal Grinding Geometry

- Mechanism: Because they wear so slowly, carbide plates maintain their original profile and the critical tight clearance with the roll ends for much longer.

- Productivity Impact:

- Consistent Throughput & Power Draw: Prevents the gradual decline in feed rate and specific energy consumption caused by side leakage.

- Improved Product Size Distribution: Consistent confinement ensures a stable particle bed, leading to a more predictable and finer crusher product with a higher degree of micro-cracking.

3. Enhanced Operational Stability and Control

- Mechanism: Stable wear plates geometry prevents the “edge effect,” edge blocks where uneven wear causes irregular pressure distribution and potential roll skewing.

- Productivity Impact:

- Reduced Mechanical Stress: Protects the rolls, bearings, and frame from uneven loads, reducing maintenance.

- Stable Operation: Allows the HPGR to operate at its design pressure and throughput consistently, simplifying process control.

4. Lower Total Cost of Ownership (TCO)

- Mechanism: While the initial capital outlay for carbide plates is higher, the long-term benefits far outweigh the cost.

- Productivity Impact:

- Reduced Parts & Labor Cost: Fewer plates need to be purchased, stored, and replaced.

- Lower Downtime Cost: The value of increased production from reduced unplanned stops often provides the fastest Return on Investment (ROI).

Quantifying the Benefits: A Comparative Table

| Performance Metric | Traditional Cast Iron Plates | High-Performance Carbide Plates | Impact on Productivity |

|---|---|---|---|

| Service Life | 1-3 months | 6-24+ months | ↑↑↑ Drastically reduced downtime |

| Material Hardness | ~600-800 HV | ~1300-1600 HV | ↑↑ Superior wear resistance |

| Leakage Control | Degrades quickly over time | Maintained consistently over life | ↑ Stable throughput & product quality |

| Replacement Cost (Annual) | High (frequent purchases) | Low (infrequent purchases) | ↓ Lower operating cost |

| Operational Stability | Can vary as plates wear | Highly stable | ↑ Predictable performance, less stress |

Case Study / Real-World Implication

A large copper mine was experiencing cheek plate failures on its primary HPGR every 6-8 weeks, resulting in 24 hours of downtime per changeout. After switching to custom engineered solid carbide inserts, the service life extended to 14 months.

- Downtime Avoided: ~10 fewer changeouts per year, saving 240 hours of critical production time.

- Throughput Gain: The stable confinement prevented a 5-7% throughput decline typically seen in the weeks before a cast iron plate failed.

- Financial Impact: The total savings in labor, parts, and most importantly recovered production revenue, resulted in an ROI on the carbide plates of under 4 months.

Our HPGR cheek plates and tungsten carbide wear parts are made from premium cemented carbide, specially engineered for high pressure grinding rolls (HPGR) under extreme high temperature and high wear conditions. These wear resistant tungsten carbide rings and components deliver outstanding performance in ball mills and high pressure grinding environments, providing excellent corrosion-resistant properties and significantly extending the service life of your equipment.

Through an advanced manufacturing process, we ensure every product offers superior durability, making maintenance simpler and more user-friendly while remaining highly cost effective and cost efficient. This combination not only reduces downtime and replacement frequency but also achieves extended service life, delivering maximum customer satisfaction for product developers and end-users alike.

Choose our tungsten carbide wear parts the reliable, high performance solution for cutting tools, pressure grinding rolls, and all demanding wear applications, offering exceptional value through proven product and service quality.

Conclusion

In the relentless pursuit of mining efficiency, every component matters. Researched and developed high quality carbide cheek plates are not just a incremental improvement; they are a fundamental upgrade that directly addresses the core limitations of HPGR technology in abrasive environments. By dramatically extending wear life, maintaining optimal grinding conditions, and maximizing operational uptime, they deliver a powerful boost to overall circuit productivity and a compelling reduction in total operating costs. For any operation looking to squeeze maximum value from its comminution circuit, upgrading to carbide cheek plates is a strategically sound and highly profitable decision.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear parts solutions to meet the customer requirements of industries such as iron ore, aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding